Method for reducing grounding resistance in manner of digging grounding deep well in transformer station

A grounding resistance, substation technology, applied in circuits, connections, electrical components, etc., can solve the problems of high experience requirements, impossible to talk about, waste of financial and material resources, etc., to achieve high soil resistivity, simple design, and reduce the effect of grounding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

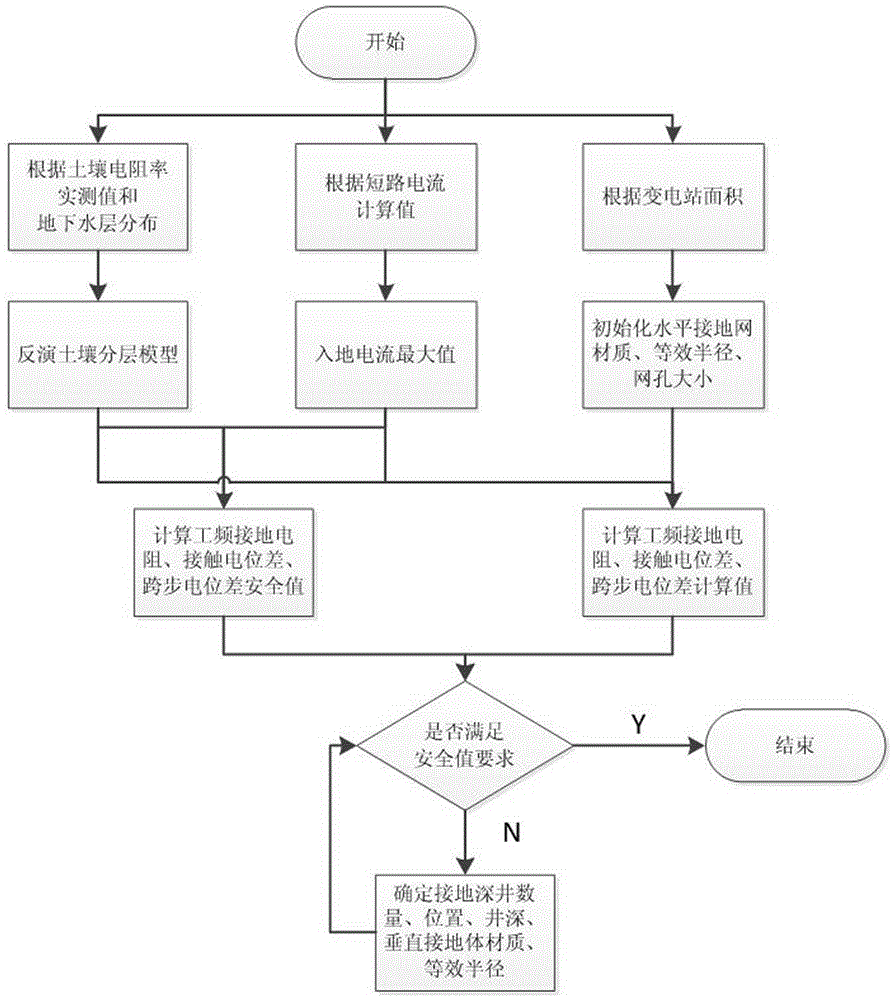

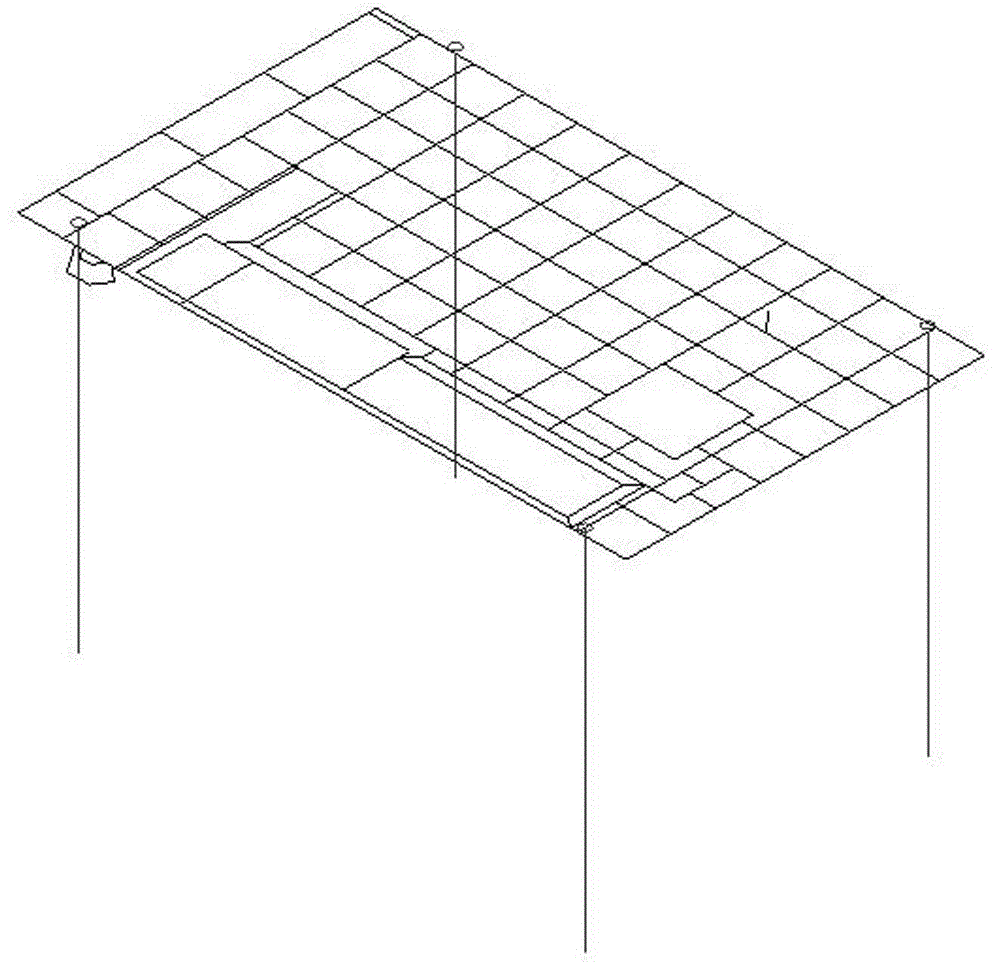

[0016] Embodiment 1, with reference to Figure 1-2 , Embodiment 1 takes a 110kV substation in Anqing, Anhui as an example:

[0017] (1) Initial conditions of substation grounding system

[0018] 1) The measured value of soil resistivity and geological conditions,

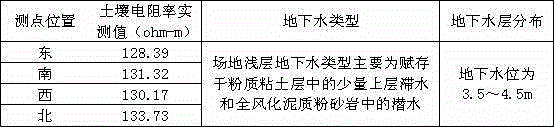

[0019] The substation is located in the Anqing area. The size of the station area is 48m×81.5m. The measured value of the soil resistivity at the location is relatively high, as shown in Table 1. According to the survey professional "Geotechnical Engineering Survey Report", the foundation rock and soil of this station are 0.5m~4.2 m is silty clay, and the buried depth of groundwater at first sight is 3.5~4.5m.

[0020] Table 1

[0021]

[0022] 2) The initial parameters of the horizontal grounding grid are shown in Table 2, and the maximum value of the calculated grounding current is 3.43kA.

[0023] Table 2

[0024] Material of horizontal ground grid Section (mm*mm) Mesh size (mm*mm) Buried ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap