A long-life wireless power transmission device between rotating interfaces of moving parts

A technology for wireless power transmission and moving parts, applied in circuit devices, electrical components, etc., can solve the problems of not fully satisfying long-life power transmission, inability to discharge during grinding, poor thermal conductivity, etc., and achieve stable and reliable power transmission process. The effect of impedance matching and extending transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

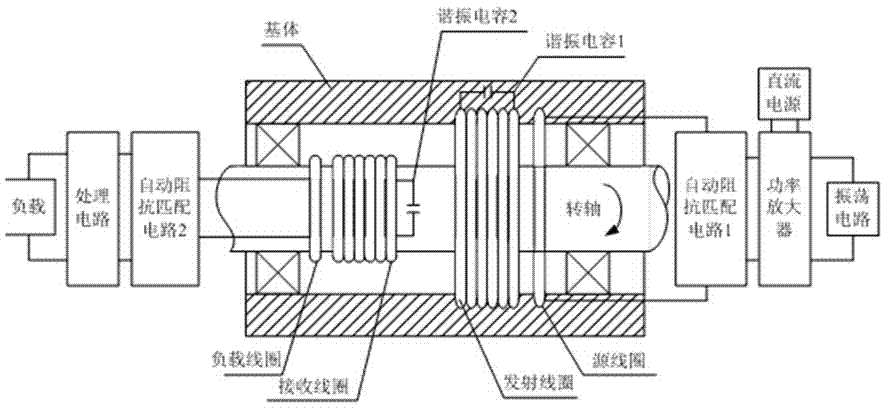

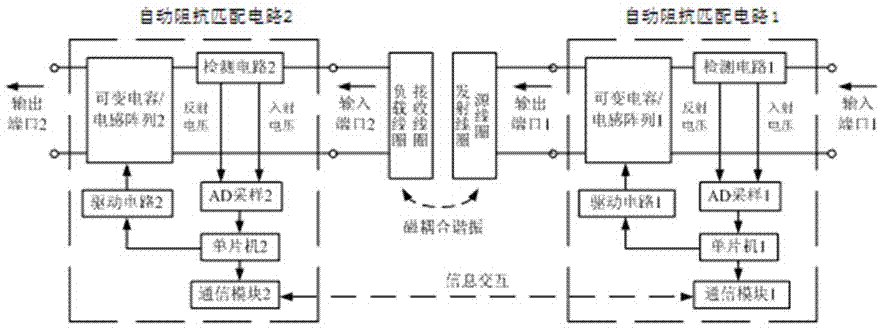

[0014] The long-life wireless power transmission device between the rotating interfaces of movable parts provided by the present invention, such as figure 1 As shown, it includes a base body, a rotating shaft set in the base body, a fixed part and a rotating part that rotates relative to the fixed part; the fixed part includes a DC power supply, an oscillating circuit, a power amplifier, an automatic impedance matching circuit 1, Source coil, transmitting coil, resonant capacitor 1, oscillation circuit, power amplifier, automatic impedance matching circuit 1, and source coil are electrically connected in sequence, the DC power supply is connected to the power amplifier, the transmitting coil is connected to resonant capacitor 1, and the transmitting coil is connected to the source coil The shaft is installed on the base body; the rotating part includes a receiving coil, a resonant capacitor 2, a load coil, an automatic impedance matching circuit 2, a processing circuit, and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com