Adaptive high-voltage frequency conversion turning method

A high-voltage variable frequency, self-adaptive technology, applied in electrical components, control systems, AC motor control, etc., can solve problems such as unstable rotor speed, and achieve the effect of solving unstable rotor speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

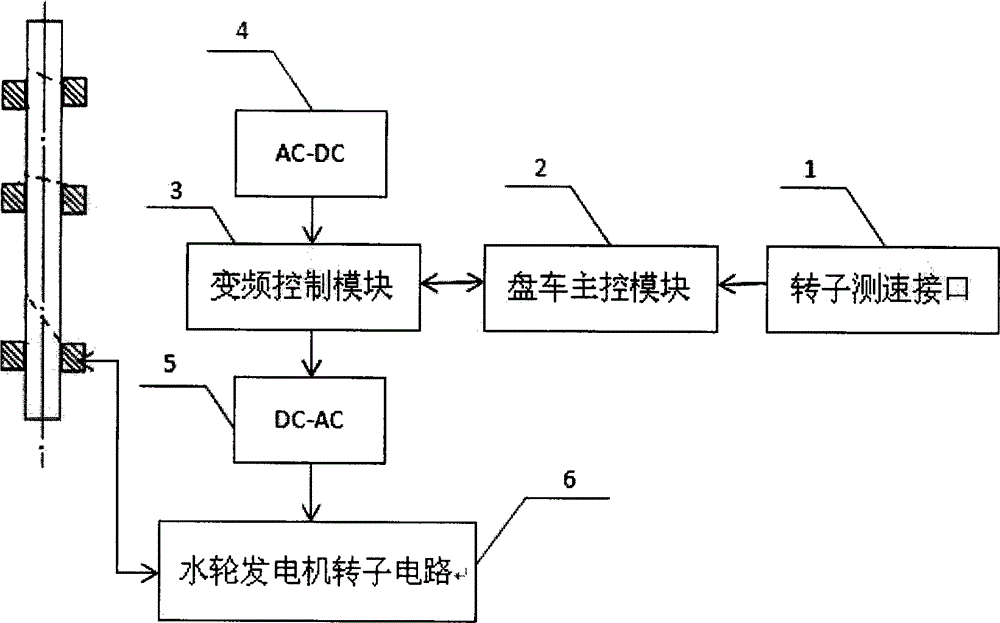

[0007] exist figure 1 Among them, the cranking main control module (2) receives the stator magnetic field pole data of the speed measuring device through the rotor speed measuring interface (1), the speed data is processed by frequency algorithm to obtain the corresponding frequency suitable for the speed, and the calculated frequency signal is sent to To the frequency conversion control module (3), the frequency conversion control module (3) controls the rotor circuit (6) of the hydro-generator through the DC-to-AC module (5), and the frequency algorithm calculates the rotor speed from the magnetic pole data of the stator magnetic field through the algorithm, and calculates the rotor speed according to the speed The switch switching frequency required by the frequency conversion control module is obtained, so as to realize more precise stepless frequency conversion speed control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com