Car tyre

A technology for automobile tires and tires, which is applied to tire parts, tire treads/tread patterns, vehicle components, etc. It can solve problems such as increased load, excessive and very sudden changes in tread marks, and reduced load, etc., to achieve Effects of increased structural rigidity, excellent drivability, and high structural uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

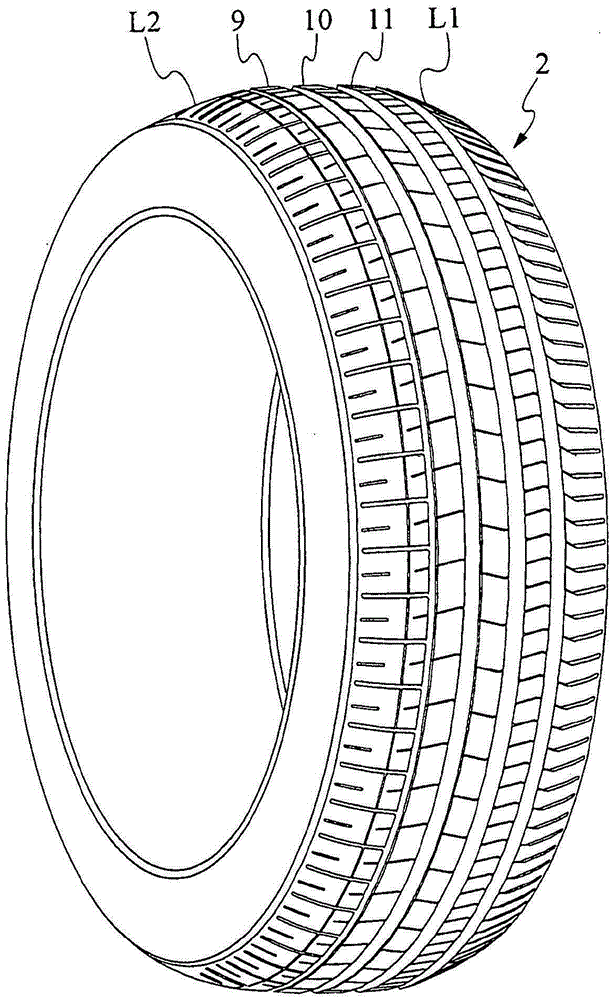

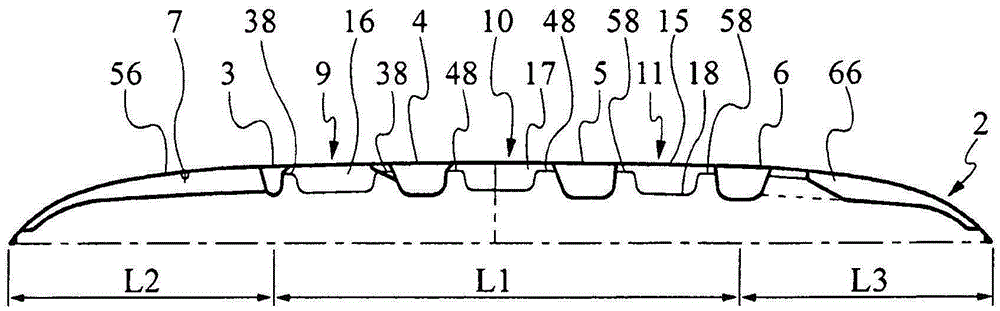

[0067] exist Figure 2 to Figure 7 In , a tire 1 with a tread 2 according to the invention is shown.

[0068] The tire 1 is of conventional construction and comprises: a carcass; a tread band located at the top of the carcass; a pair of axially opposite sidewalls terminating in a In the bead reinforced by the bead core and the corresponding bead filler. The tire preferably also comprises a belt structure interposed between the carcass and the tread band. The carcass is reinforced by one or more carcass plies secured to bead cores, while the belt structure consists of two belt strips radially superimposed on each other. The belt strips are formed from rubberized fabric parts enclosing metal cords in each belt strip parallel to each other and intersecting the metal cords in adjacent belt strips and preferably The metal cords in adjacent belt strips are inclined symmetrically with respect to the equatorial plane. Preferably, the belt structure further comprises a third belt l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com