Device for sealing and evacuating a container having a paste-like liquid

A technology for containers and liquids, applied in devices for coating liquids on surfaces, liquid distribution, transport or transfer devices, distribution devices, etc., can solve problems such as damage, material sealing, production process interruption, etc., to achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

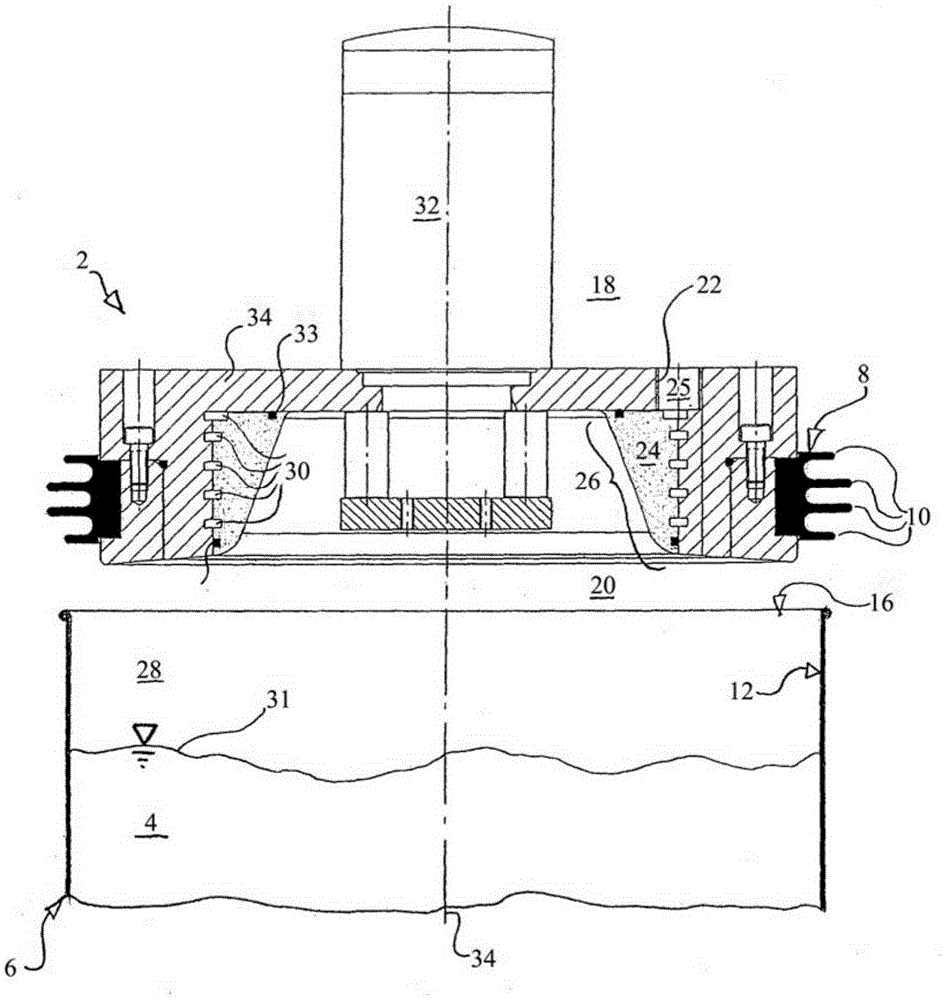

[0022] The device 2 shown in the figures is used to seal and empty a container 6 of a particularly viscous liquid 4, or to apply air pressure to the liquid.

[0023] The device 2 has a cylindrical rubber seal 8 arranged on the circumference of the device 2 . The sealing part comprises 4 axially arranged one after the other, radially outward protruding, staggered outer diameter sheet seal rings 10 (however, all possible other sealing methods and forms can also be considered, for example with solid or hollow (hose type) cross-section of one or more sealing rings). Thus, the sealing portion 8 is adapted to be placed in the cylindrical inner contour 12 of the thin steel drum 6 and is also circumferentially sealed. The inner profile of the bucket 6 matched with the device 2 of the present invention extends to the outside of the thin steel lid bucket without narrowing the size to the bung mouth 16. In order to store and transport the high-viscosity liquid contained, the bung mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com