Rotating anode mount adaptive to thermal expansion

A rotating anode and thermal expansion technology, which is applied in cold cathode manufacturing, electrode system manufacturing, X-ray tube electrodes, etc., can solve the problems of increasing anode disks, unwanted vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

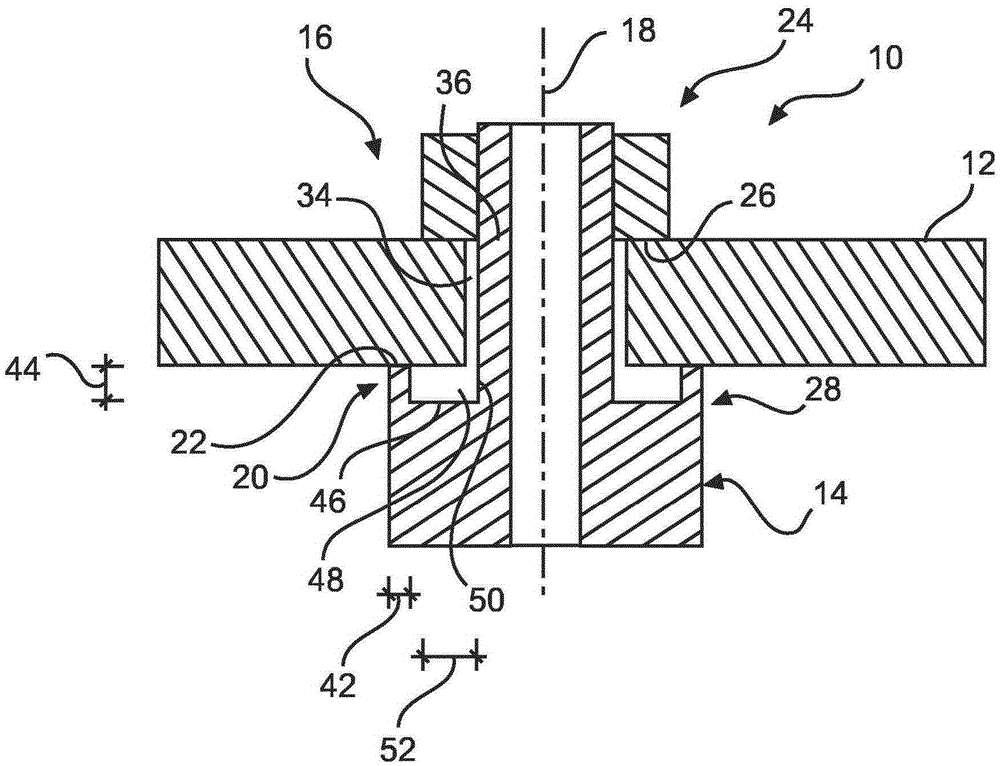

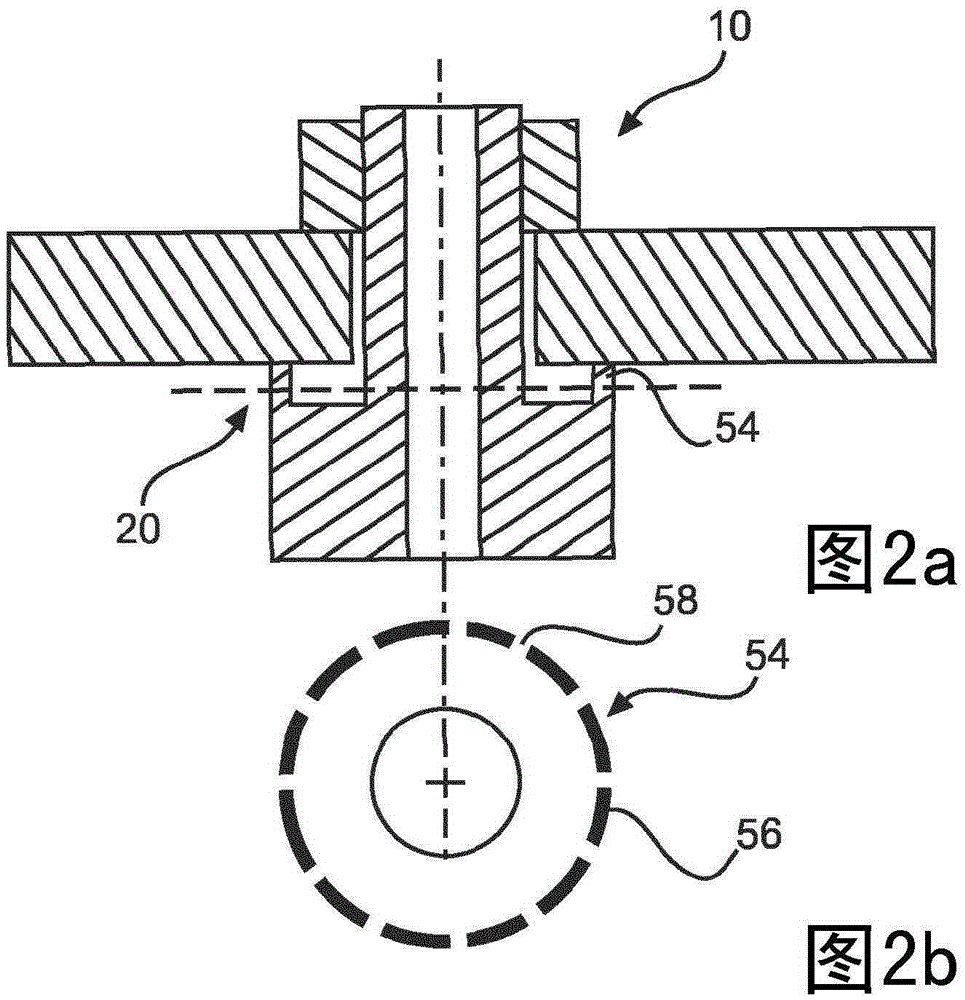

[0042] FIG. 1A shows a rotating anode assembly 10 comprising an anode disk 12 , a rotating rod 14 and an anode disk support 16 . In addition, the rotation axis 18 of the rotation rod 14 is indicated. The anode disk 12 is mounted concentrically to the rotation axis 18 of the rotation rod 14 via an anode disk support 16 . The anode disc support 16 comprises a support 20 having a first circular axial support surface 22 provided at the rotating shaft 14 concentrically with the rotating shaft 18 . The first support 20 and the first circular axial support surface 22 are further described below. The anode disc support 16 also comprises a second support 24 having a second axial support surface 26 which is at least temporarily attached to the rotating rod 14 to face in the axial clamping direction The first support surface 22 urges the anode disk 12 . The first support 20 is provided as a radially flexible support 28, also shown in FIG. 1B .

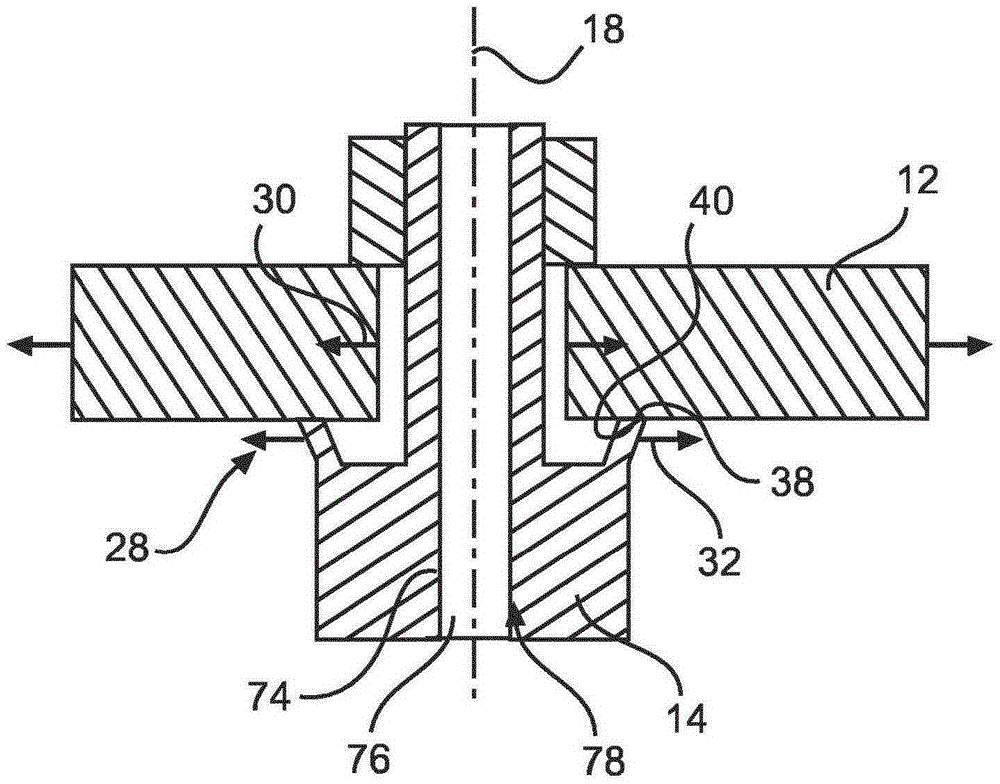

[0043] FIG. 1B shows the situation whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com