Test tube double-spray-washing and spin-drying device

A test tube, double technology, applied in the field of test tube double spray washing and drying device, can solve the problems of taking up a lot of working time, secondary pollution, human health hazards, etc., and achieve the goals of improving cleaning efficiency, accurate automatic cleaning, and early start time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

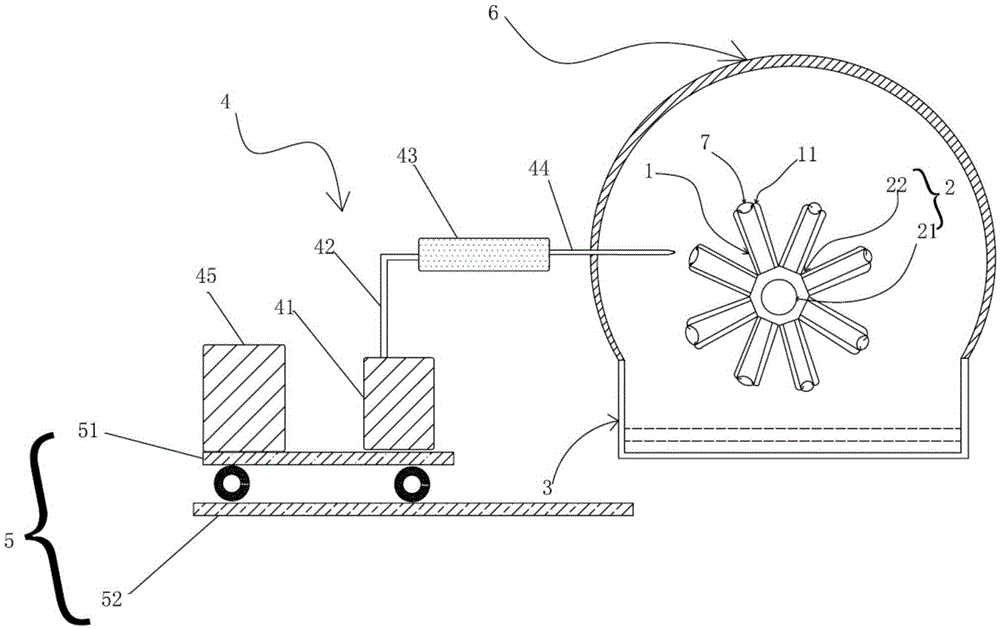

[0021] See figure 1 , Which is a schematic diagram of the structure of the test tube double spray washing and spin drying device of the present invention.

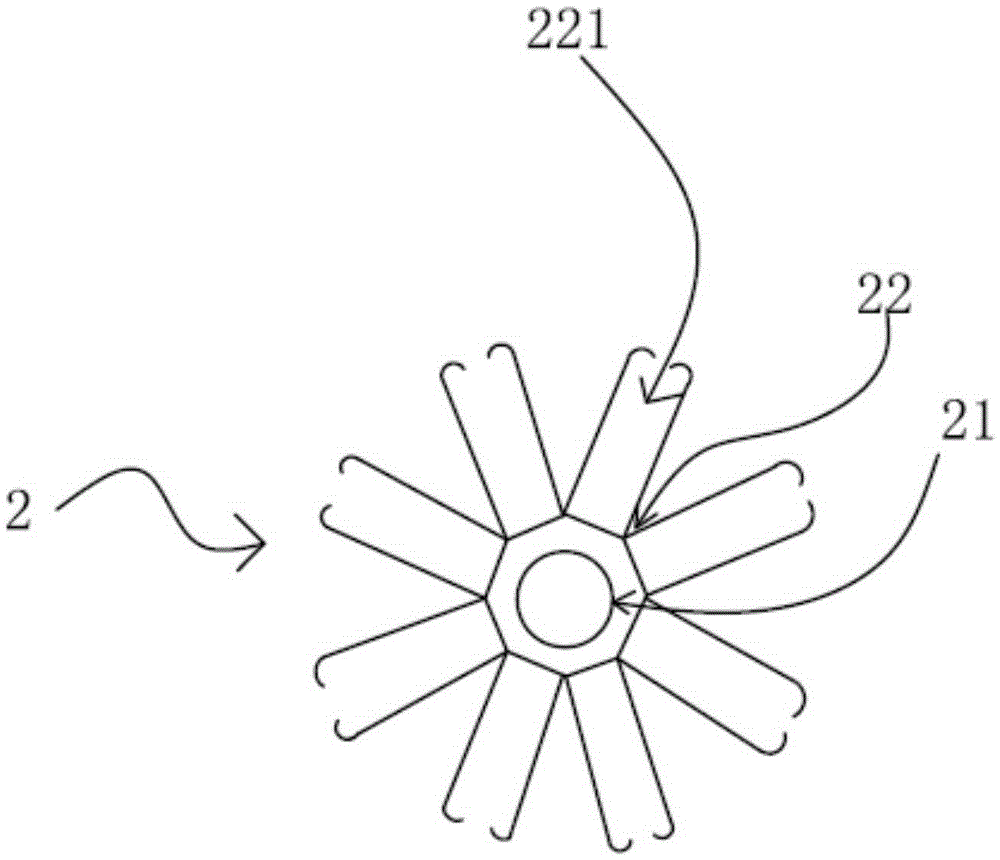

[0022] The invention provides a test tube double spray washing and drying device, which comprises a clamping mechanism 1, a rotating mechanism 2, a waste liquid tank 3, a spray washing mechanism 4, a driving mechanism 5 and a sealing cover 6.

[0023] The clamping mechanism 1 is arranged on the rotating mechanism 2 for fixing the test tube 7 in the clamping mechanism 1.

[0024] The rotating mechanism 2 is used to control the rotation of the clamping mechanism 1.

[0025] The waste liquid tank 5 is arranged below the rotating mechanism 2.

[0026] The sealing cover 6 covers the clamping mechanism 1 and the rotating mechanism 2, and the bottom of the sealing cover 6 is attached to the upper edge of the waste liquid tank. The sealing cover 6 is provided with a spray washing opening 61.

[0027] The spray cleaning mechanism 4 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com