Installation tool for suspension seat of dump truck frame

A technology for installing tooling and suspension seats, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inaccurate installation positions of suspension seats, long-time adjustment and fixing, and lack of positioning tooling for vehicle frames, etc., to achieve The effect of light weight, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further explained below in conjunction with the accompanying drawings of the specification.

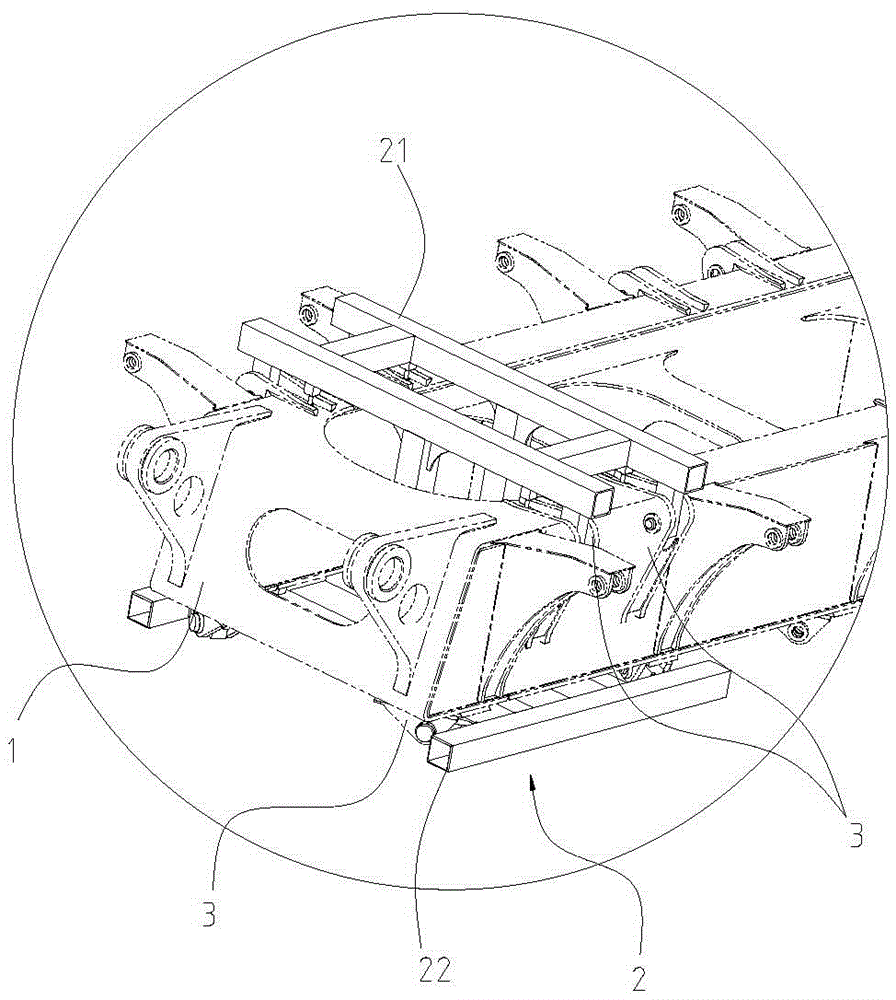

[0022] Such as figure 1 As shown, a tool for installing a suspension seat of a dump truck frame includes an upper clamp 21 and a lower clamp 22 matched with the upper clamp 21.

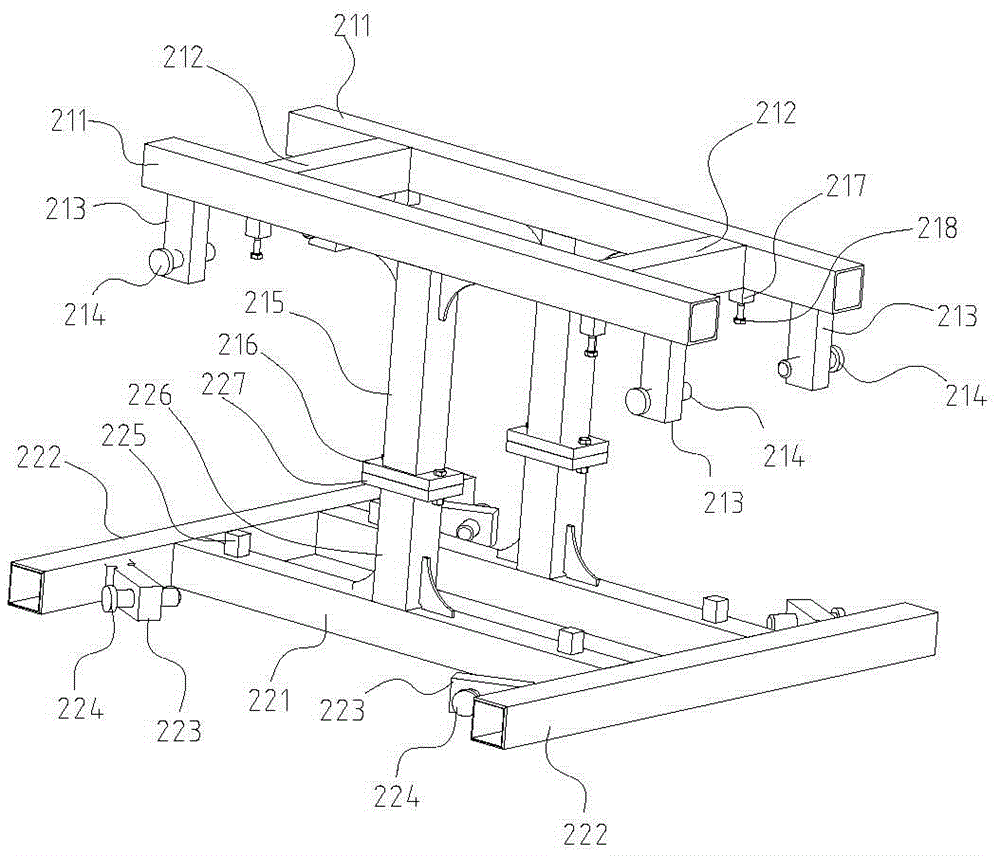

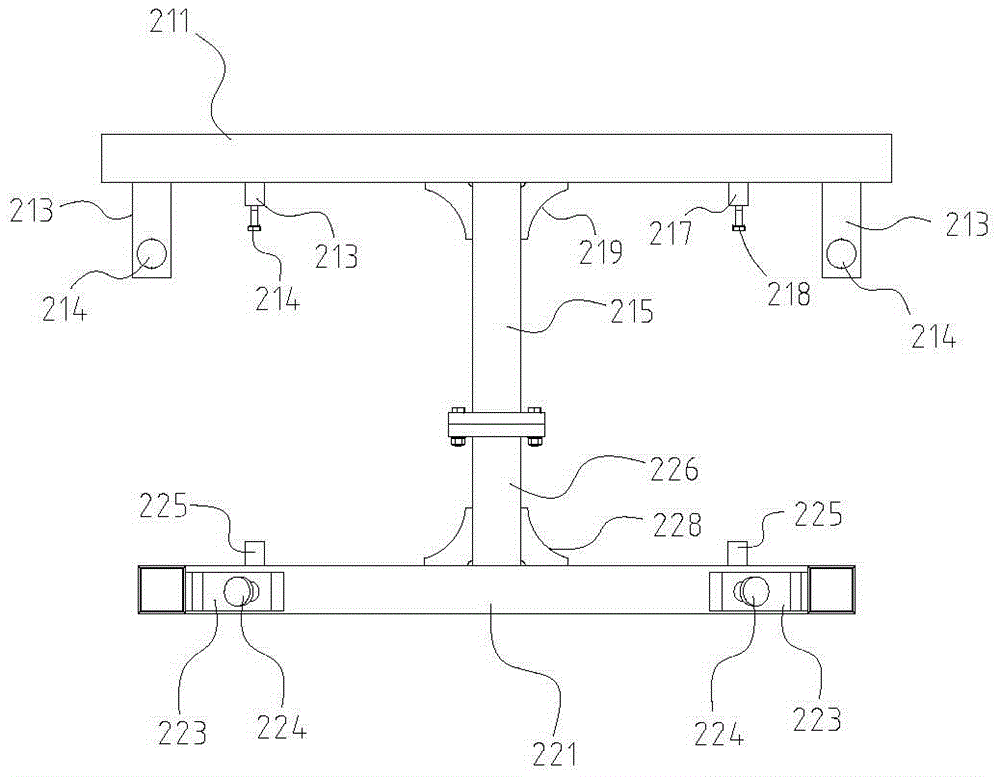

[0023] Such as Figure 2 to 4 As shown, the upper clamp 21 includes two first pressure rods 211 arranged parallel to each other, and a connecting rod 212 is provided between the two first pressure rods 211 to connect the two first pressure rods 211 into one body. The bottom of both ends of the first pressure rod 211 is provided with first positioning seats 213. The length of the first pressure rod 211 is slightly longer than the width of the frame 1, so that the first positioning seats 213 are located on both sides of the frame 1. A positioning seat 213 and the first pressing rod 211 are perpendicular to each other; the first positioning seat 213 is provided with a first positioning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com