Prefabricated assembled cover beam structure and construction method using steel shear key

A technology of prefabricated assembly and construction method, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of low occlusal matching degree and complicated construction, and achieve the improvement of aging performance, saving template materials, and high matching degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

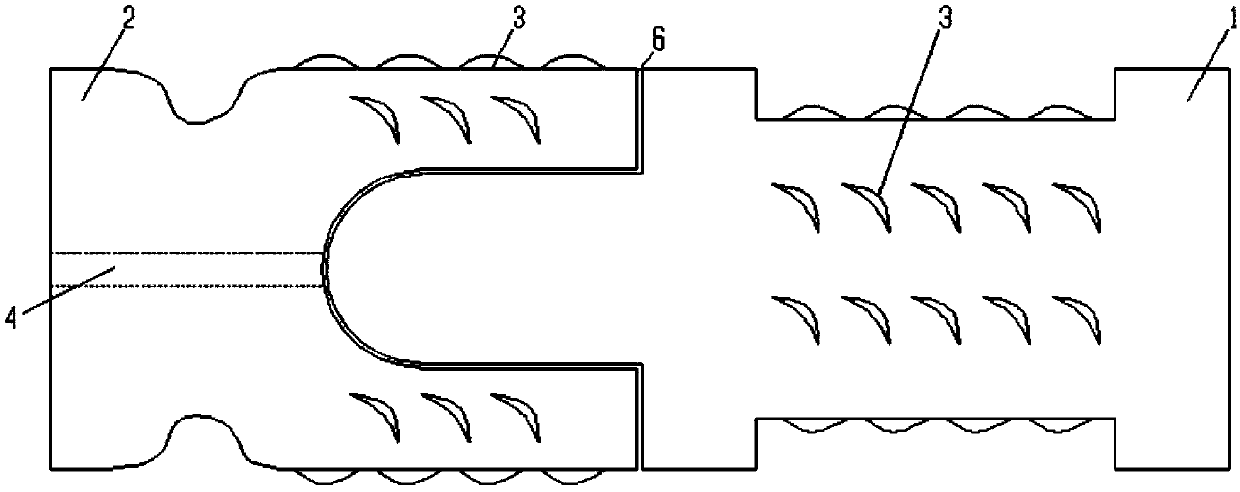

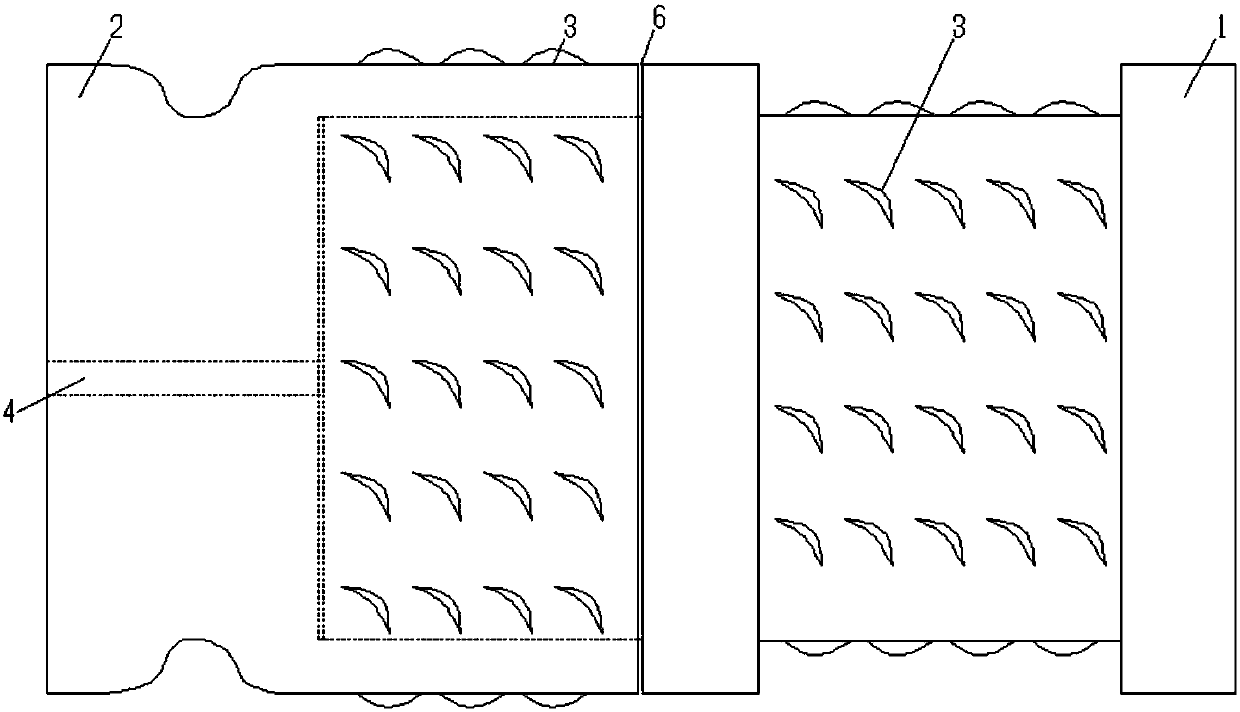

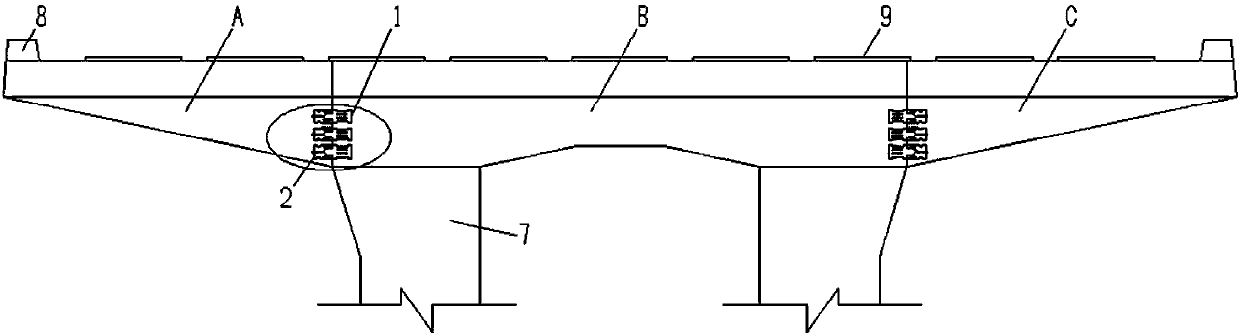

[0030] Such as Figure 1 to Figure 6 As shown, the prefabricated assembled cover beam structure using steel shear keys of the present invention includes concrete components of the prefabricated cover beam, steel shear keys, grouting holes 4, PVC pipes 5, and the like. The concrete components of the prefabricated cover beams are connected by pre-embedded steel shear keys. A single steel shear key is divided into a male shear key 1 and a female shear key 2. The boss on the male shear key 1 is connected to the The grooves on the female shear key 2 are paired and connected, and the steel shear key is cast from ductile iron or high-quality carbon structural steel; the male shear key 1 and the female shear key 2 are on the contact surface with the concrete There are crescent patterns 3, the purpose of which is to generate mechanical engagement with concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com