Air gun cylinder cover rotating structure

A technology of rotating structure and cylinder head, applied in the field of air guns, can solve the problems of lower efficiency, high labor cost, easy to connect wrong lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

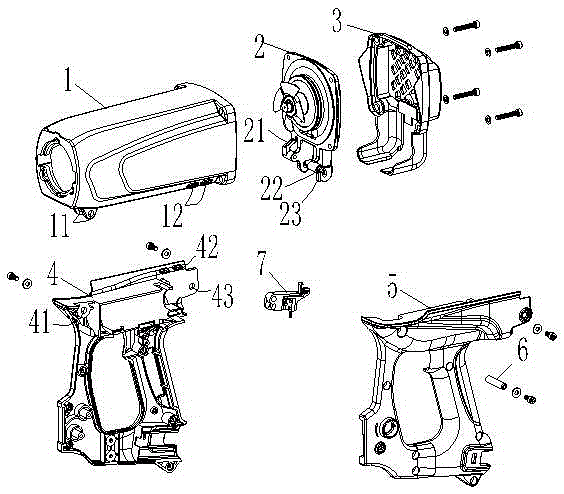

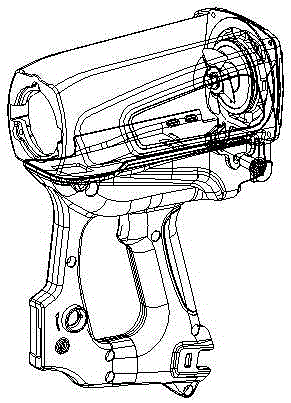

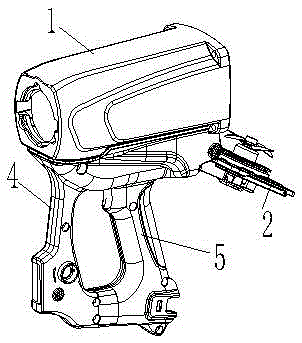

[0032] Such as figure 1 , 2 As shown, a cylinder head rotation structure of an air gun includes a casing 1, a cylinder head 2, a rear cover 3, and a handle. The handle is detachably connected to the bottom of the casing 1, and the rear cover 3 covers the cylinder head 2. And it is detachably connected to the end of the shell 1 together with the cylinder head 2, and the bottom of the cylinder head 2 is connected to the handle in rotation. The core components installed in the shell 1 are as image 3 shown.

[0033] The handlebar is divided into two parts, the right-hand handle 4 and the left-hand handle 5, as Figure 4 , 5 shown. The right-hand handle 4 and the left-hand handle 5 are respectively fixed on both sides of the bottom of the housing 1 , and the bottom of the cylinder head 2 is rotatably connected between the right-hand handle 4 and the left-hand handle 5 .

[0034] A connection hole 11 is provided on both sides of one end of the bottom of the housing 1, and a s...

Embodiment 2

[0038] Such as figure 1 , 2 As shown, a cylinder head rotation structure of an air gun includes a casing 1, a cylinder head 2, a rear cover 3, and a handle. The handle is detachably connected to the bottom of the casing 1, and the rear cover 3 covers the cylinder head 2. And it is detachably connected to the end of the shell 1 together with the cylinder head 2, and the bottom of the cylinder head 2 is connected to the handle in rotation. The core components installed in the shell 1 are as image 3 shown.

[0039] The handlebar is divided into two parts, the right-hand handle 4 and the left-hand handle 5, as Figure 4 , 5 shown. The right-hand handle 4 and the left-hand handle 5 are respectively fixed on both sides of the bottom of the housing 1 , and the bottom of the cylinder head 2 is rotatably connected between the right-hand handle 4 and the left-hand handle 5 .

[0040] A connection hole 11 is provided on both sides of one end of the bottom of the housing 1, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com