Sheet-fed printing press ink fountain with fluorocarbon resin coating and color separating device

A technology for printing presses and ink fountains, applied in the field of ink fountain color separation devices of printing presses, can solve the problems of swelling deformation, adverse effects of operating environment, low efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

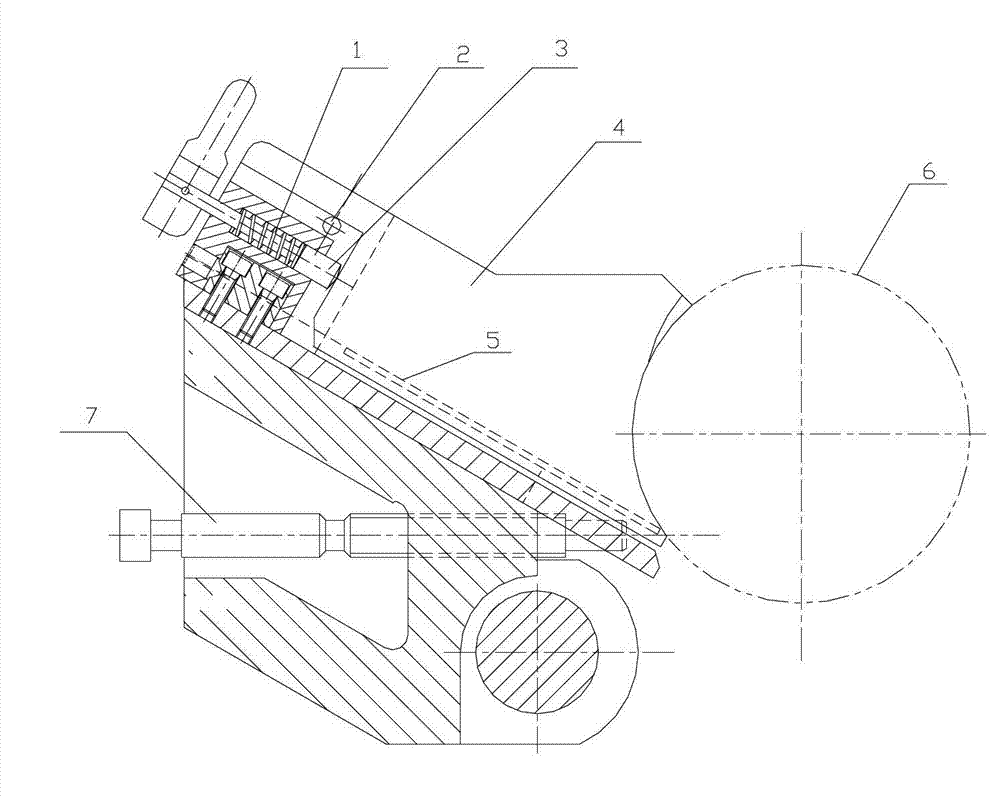

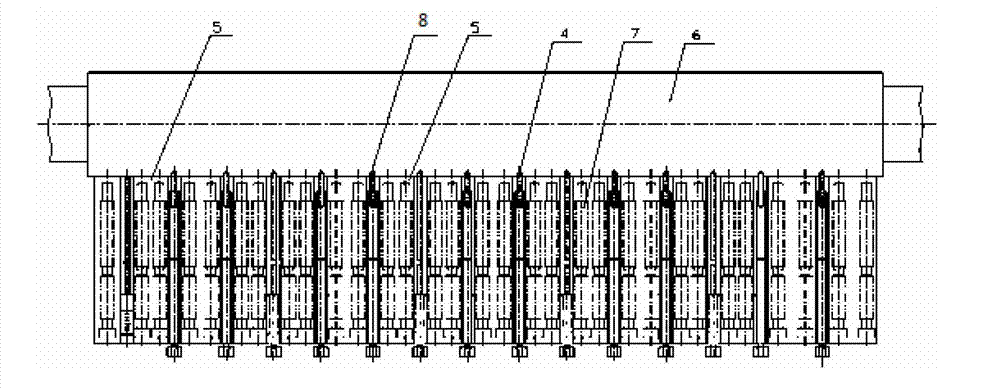

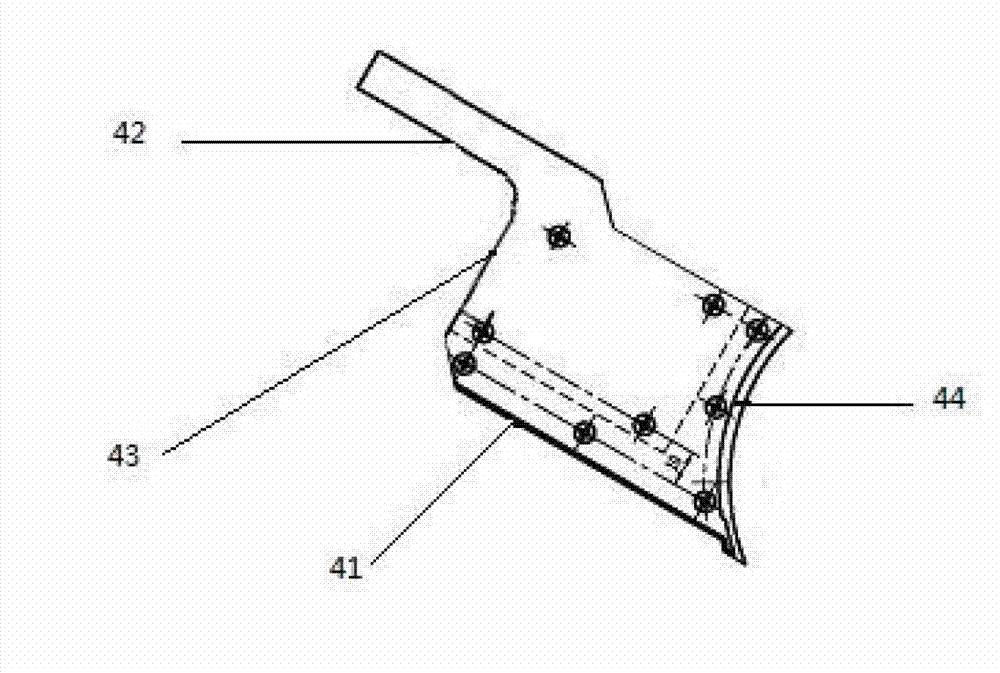

[0022] like figure 1 and figure 2 As shown, the ink fountain color separation device of the printing machine includes a plurality of ink fountain blades 5 and a plurality of color separation sheets 4, and also includes a plurality of color separation sheet supports 9, and gaps are provided between adjacent ink fountain blades 5, which are independent of each other, and the ink fountain blades 5 The width of the color spacer is determined by the specifications of the product; the color spacer bracket 9 is installed in the gap between the adjacent ink fountain blades 5, and there is a groove in the middle of the color spacer bracket 9; the color spacer 4 is inserted in the groove, and the color spacer Sheet bottom 41 and groove bottom are provided with space, and the upper end 42 of color-separating sheet afterbody is fixed on the pivot point 2, and the lower end 43 of color-separating sheet afterbody is connected with the position adjuster that is made of spring 1 and push pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com