A Material Alignment and Feeding Control System

A control system and controller technology, applied in the field of sanitary napkins, can solve the problems of reducing equipment production efficiency, waste products, and failure to position and dock normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

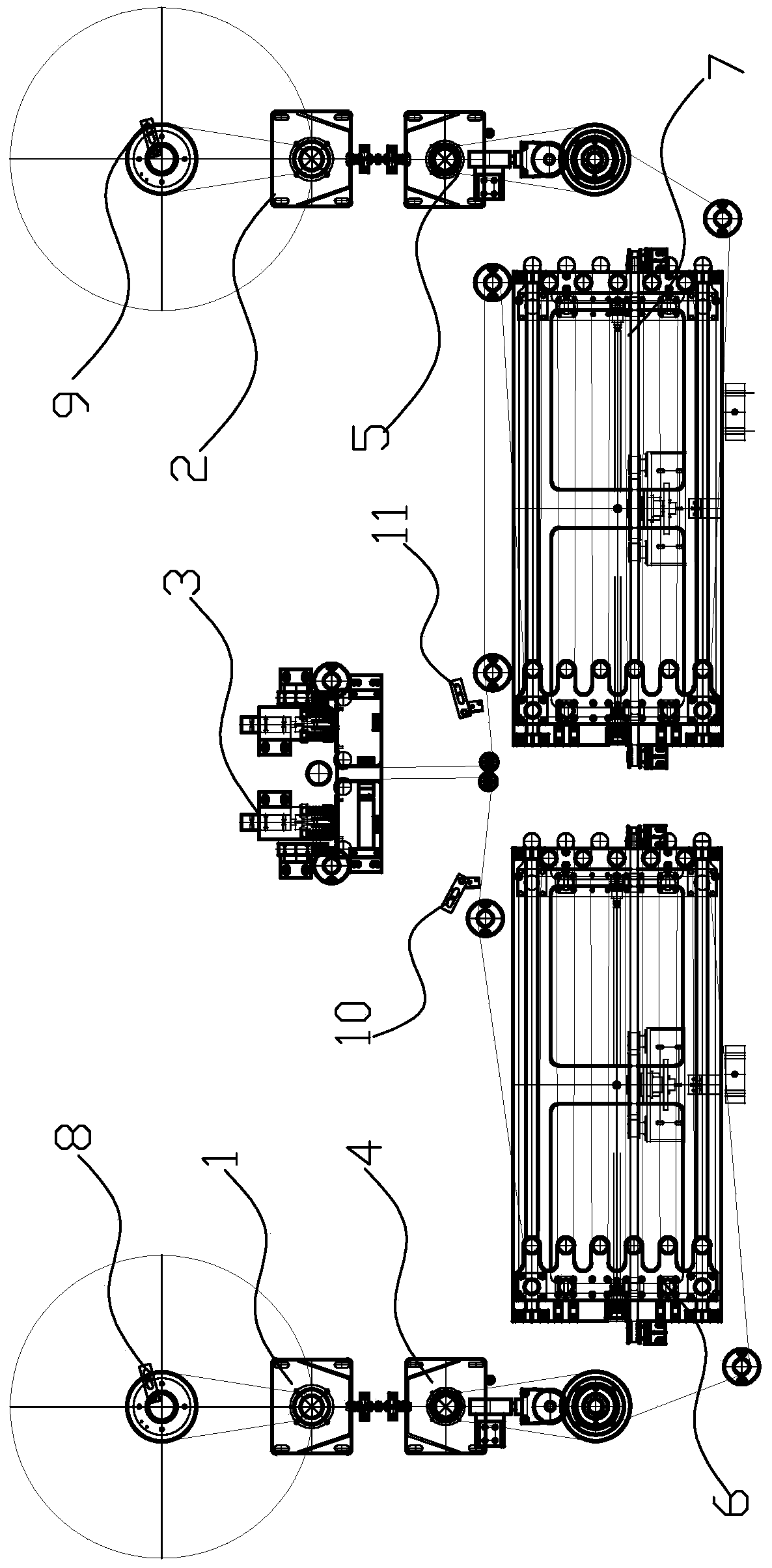

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0010] refer to figure 1 , the preferred material alignment material receiving control system of the present invention is characterized in that it includes a frame, a first unwinding mechanism 1, a second unwinding mechanism 2, a material changing mechanism 3, and a first material fixed-length conveying mechanism 4 , the second material fixed-length conveying mechanism 5, the first material storage mechanism 6, the second material storage mechanism 7, the first acceleration sensor 8, the second acceleration sensor 9, the first color mark sensor 10, the second color mark sensor 11, The third color mark sensor, the fourth color mark sensor, PLC controller and control panel, the material changing mechanism 3, the first material fixed-length conveying mechanism 4, the second material fixed-length conveying mechanism 5, the first material storage mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com