Bitobar flowmeter

A technology of Pitoba flowmeter and flow totalizer, which is applied in the field of flowmeters, can solve the problems of poor pressure taking effect, easy loosening or even falling off, and inaccurate gas flow measurement in pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

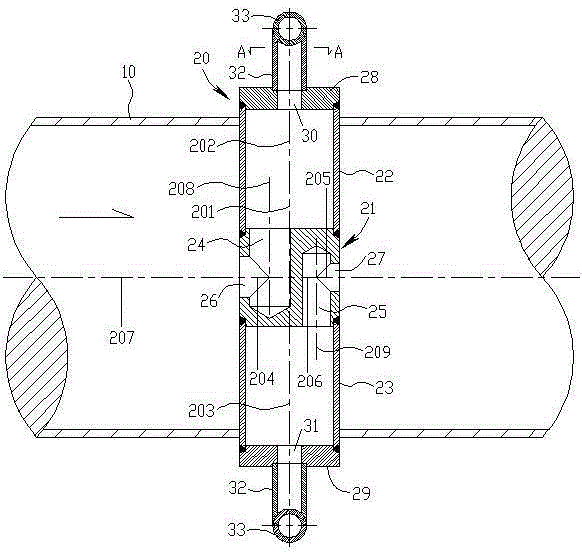

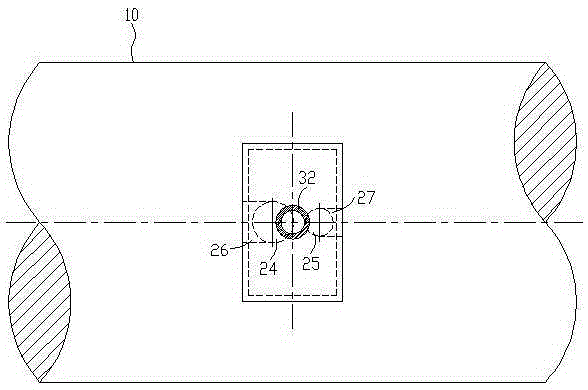

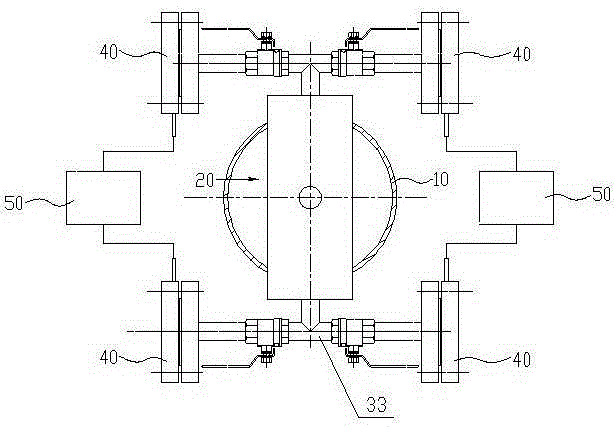

[0012] see figure 1 - image 3 , the Bitoba flowmeter of the present invention includes a sensor 20, a differential pressure transmitter 40 and a flow totalizer 50, and also includes a pipeline section 10, the sensor 20 is inserted into the pipeline section 10, and the sensor 20 includes Straight hexahedral pressure taking head 21 and the full pressure guide square tube 22 and static pressure guide square tube 23 that are sealed and connected to the upper and lower ends of the straight hexahedron shape pressure get head, the full pressure guide square tube 22 and the static pressure guide The square tubes 23 are sealed and fixedly connected with the pipeline section 10 respectively, and the upper end of the full-pressure guiding square tube 22 and the lower end of the static pressure guiding square tube 23 respectively extend out of the pipeline section 10, and the straight hexahedral pressure-taking head 21 is provided with The full pressure semi-hole 24 and the static press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com