A device and method for testing vibration absorber frequency

A vibration absorber and frequency technology, which is applied in the field of devices for testing the frequency of vibration absorbers, can solve the problems of lowering work efficiency, inconsistency of test results, and non-uniformity of single vibration absorbers, and achieves the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

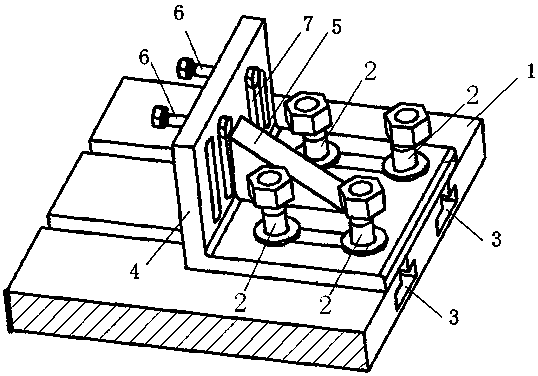

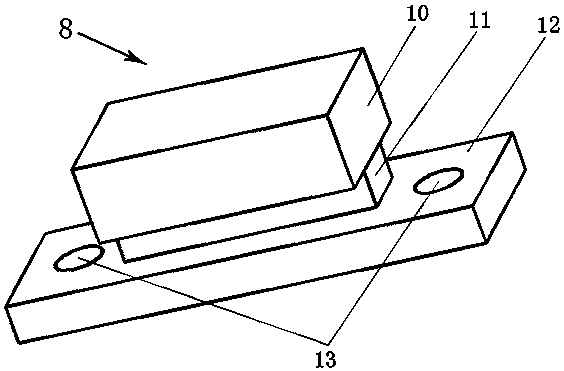

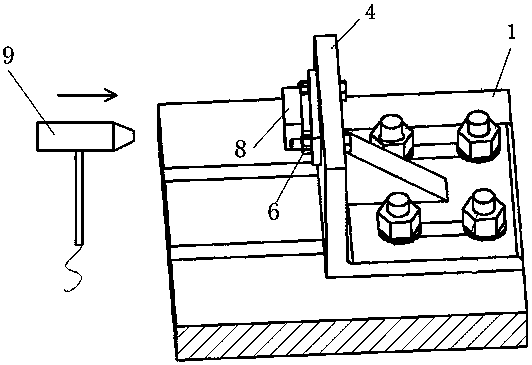

[0021] The device for testing the vibration absorber frequency of the present invention includes a data acquisition front end, a force hammer 9, an acceleration sensor and a vibration absorber fixing device, such as figure 1 As shown, the shock absorber fixing device includes a floor 1 and a base 4, the base is L-shaped, its horizontal part is fixed to the floor, and its vertical part is provided with two vertical first strip-shaped holes 7 , the spacing between the two first strip-shaped holes is equal to the spacing between the two bolt holes 13 on the mounting bracket of the vibration absorber to be tested, and the first bolt 6 passes through the two first strip-shaped holes Holes 7 and two bolt holes 13 on the absorber mounting bracket 12 secure the absorber to the vertical portion of the base. The two vertical first strip-shaped holes provided on the vertical pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com