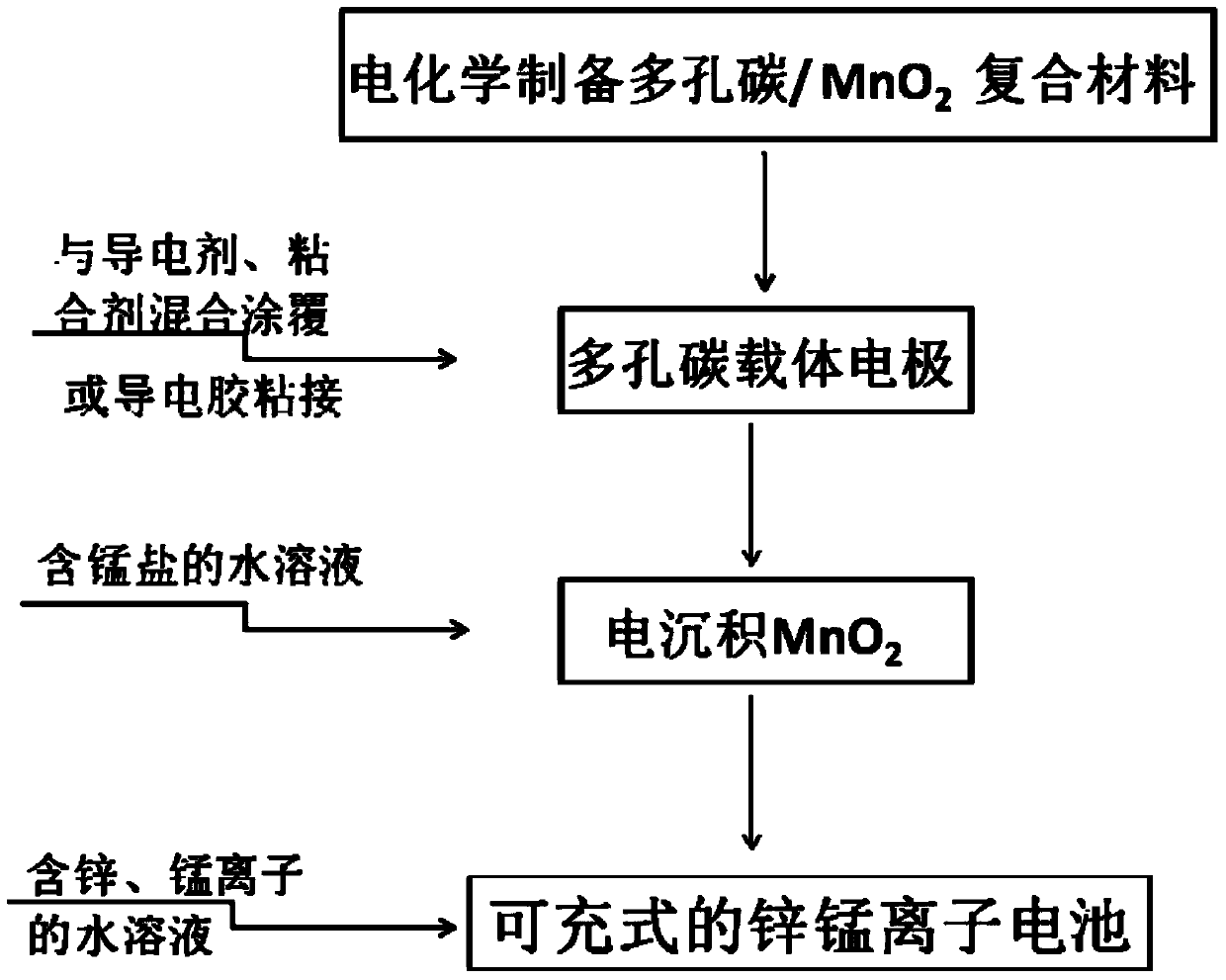

A kind of porous carbon/manganese dioxide composite material electrode, its preparation method and rechargeable zinc-manganese ion battery

A manganese dioxide and composite material technology, applied in the field of electrochemistry, can solve the problems of poor rate performance, poor conductivity, large particle size, etc., and achieve the effects of increasing the active specific surface, improving the filling rate, and improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Stainless steel mesh with a cutting area of 20×20mm and graphite felt with a cutting area of 20×20×1mm are used as the substrate and porous carbon carrier electrode respectively. The graphite felt is bonded to the stainless steel substrate electrode with graphite emulsion conductive adhesive, and the metal tab is welded on the stainless steel mesh. , to make the working electrode. Put the prepared graphite felt electrode into a solution containing 1 mol / L manganese acetate and 1 mol / L sodium sulfate to form an electrolytic cell with a metal zinc sheet, adjust the pH to 5, and the solution is in a flowing state, and the selected potential value is 2.0 V vs .Zn / Zn 2+ , and performed potentiostatic electrolysis at room temperature for 1 h. The electrode was taken out, washed with deionized water, dried, and weighed. With the obtained graphite felt / manganese dioxide composite electrode as positive electrode and zinc electrode as negative electrode, 1M ZnSO 4 +1M Na ...

Embodiment 2

[0030] 0.25 g of commercial carbon nanotubes were heated and mixed in a mixed acid solution of sulfuric acid and nitric acid (volume ratio 3:1) for purification, and then washed and dried. Add 5% binder PTFE to the dried carbon nanotubes, roll them into sheets, and press the pole pieces with a cutting area of 20×20 mm on a stainless steel mesh, and dry them in a vacuum to form carbon nanotube electrodes. Put the prepared carbon nanotube electrode into a solution containing 0.5 mol / L manganese sulfate and 1 mol / L sodium sulfate to form an electrolytic cell with metal zinc sheet, adjust the pH to 5, and the solution is in a flowing state, with a current of 10mA, room temperature Under constant current electrolysis for 2.5 hours. The electrode was taken out, washed with deionized water, dried, and weighed. With the obtained carbon nanotube / manganese dioxide composite as the positive electrode and the zinc electrode as the negative electrode, 2MZnSO 4 +0.5M MnSO 4 The aqueous...

Embodiment 3

[0032] Graphene powder, conductive agent carbon black and binder polyvinylidene fluoride are mixed in a mass ratio of 8:1:1 and then coated on stainless steel mesh, cut into a certain size, and dried in a vacuum to form graphene electrode. Put the prepared graphene electrode into a solution containing 1 mol / L manganese sulfate and 1 mol / L sodium sulfate to form an electrolytic cell with a metal zinc sheet, adjust the pH to 4.5, and the solution is in a flowing state, and the selected potential value is 2.0 Vvs. Zn / Zn 2+ , at room temperature for 2 h at constant potential pulse electrolysis. The electrode was taken out, washed with deionized water, dried, and weighed. With the obtained graphene / manganese dioxide composite as positive electrode and zinc electrode as negative electrode, 1M ZnSO 4 +1M Na 2 SO 4 +1M MnSO 4 The aqueous solution is used as the electrolyte to assemble the battery, its specific capacity is 230 mAh / g, and the capacity retention rate is over 80% af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com