Internal carrier module for communication cabinet

A technology for carrying modules and communication cabinets. It is used in data centers, support structure installation, installation board safety devices, etc. It can solve the problems of non-adjustable width, difficult processing, and difficult assembly, and achieve adjustable height and connection. Simple way, efficient and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing of description, the present invention will be further described.

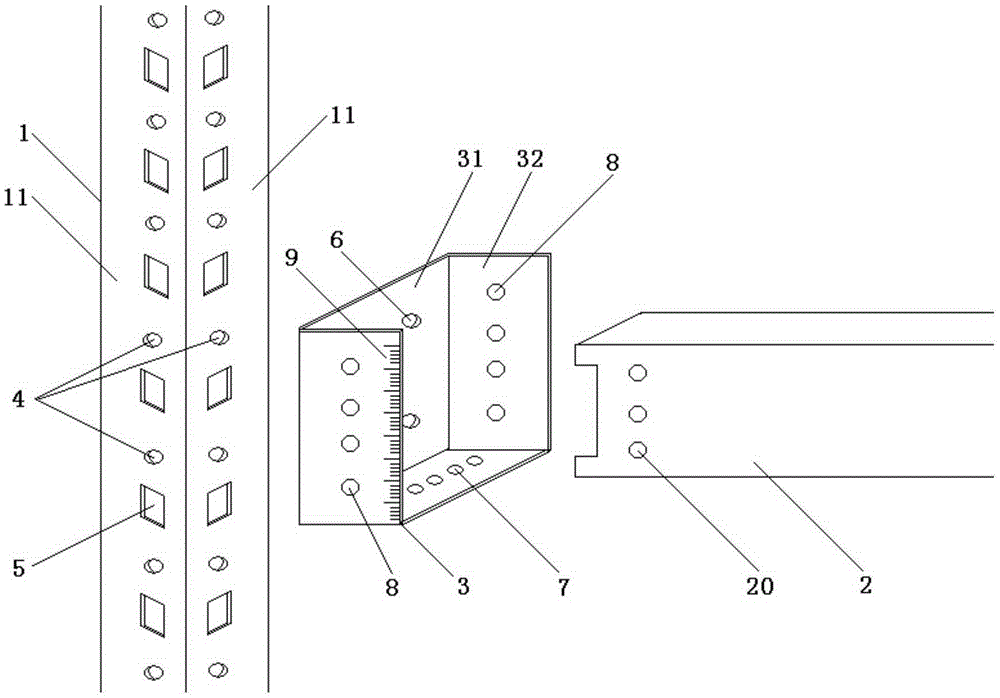

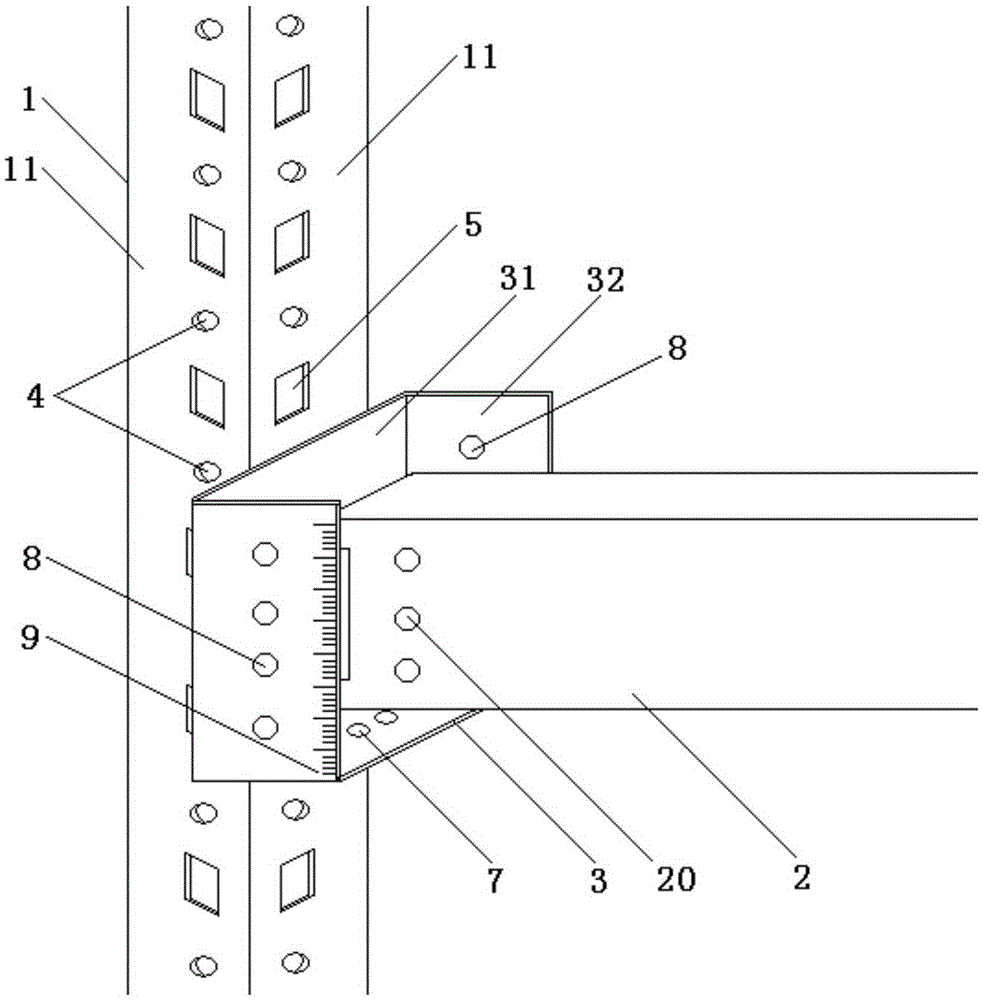

[0026] Such as figure 1 and figure 2 The shown load-carrying module in the cabinet suitable for communication cabinets includes a vertically distributed column 1 and a horizontally distributed installation bar 2 arranged in the cabinet, and the installation bar 2 is connected to the column 1 through an adapter 3; The column 1 is hollow and square. Two rows of through holes 4 in the shape of circular bolt holes distributed at equal intervals are opened on the cylindrical surface 11 of the column 1 along the axial length direction. The two rows of through holes 4 are respectively located on the adjacent two cylindrical surfaces 11. Above; the cylindrical surface 11 of the column 1 along the axial length direction is provided with square holes 5 that are coaxial with the through holes 4 and distributed at equal intervals, and the square holes 5 are located be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com