Correcting device for correcting shape of opening of conveying pipe

A technology for conveying pipes and nozzles, applied in the field of pipe butt joints, which can solve the problems of long correction time and achieve the effects of short correction time, convenient and quick use, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

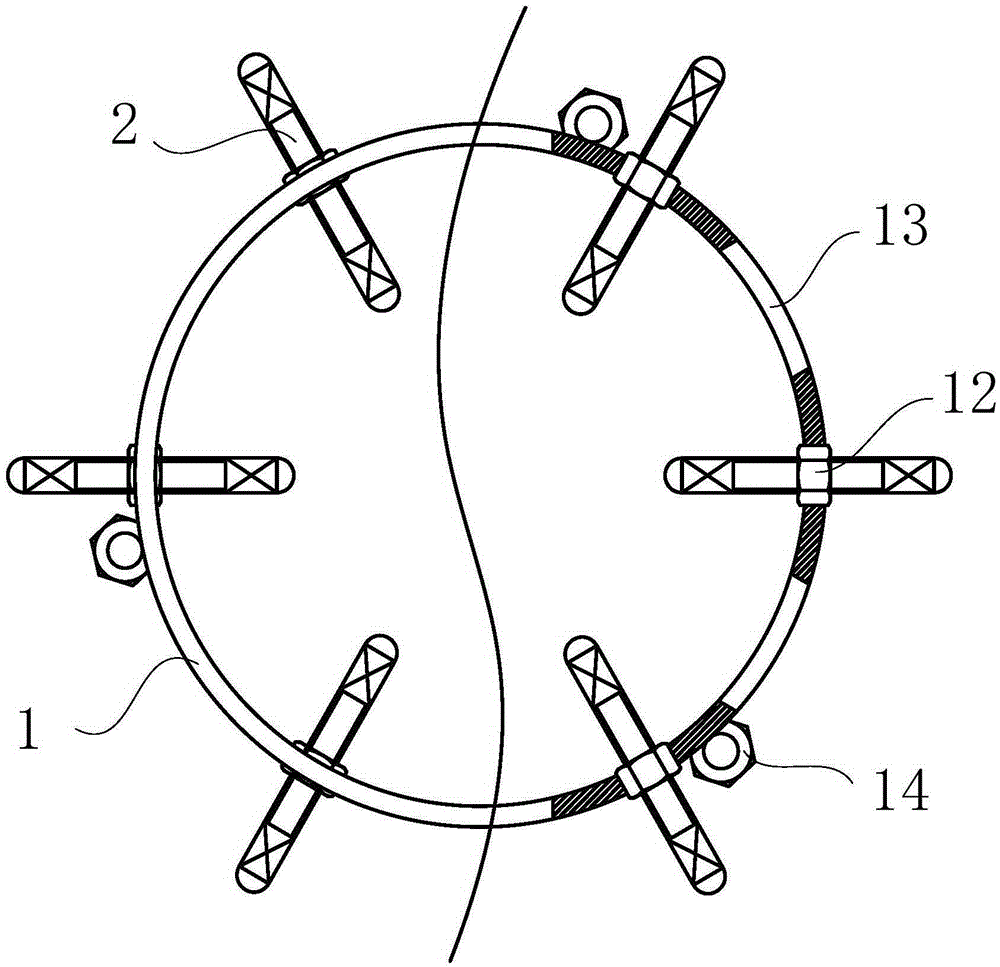

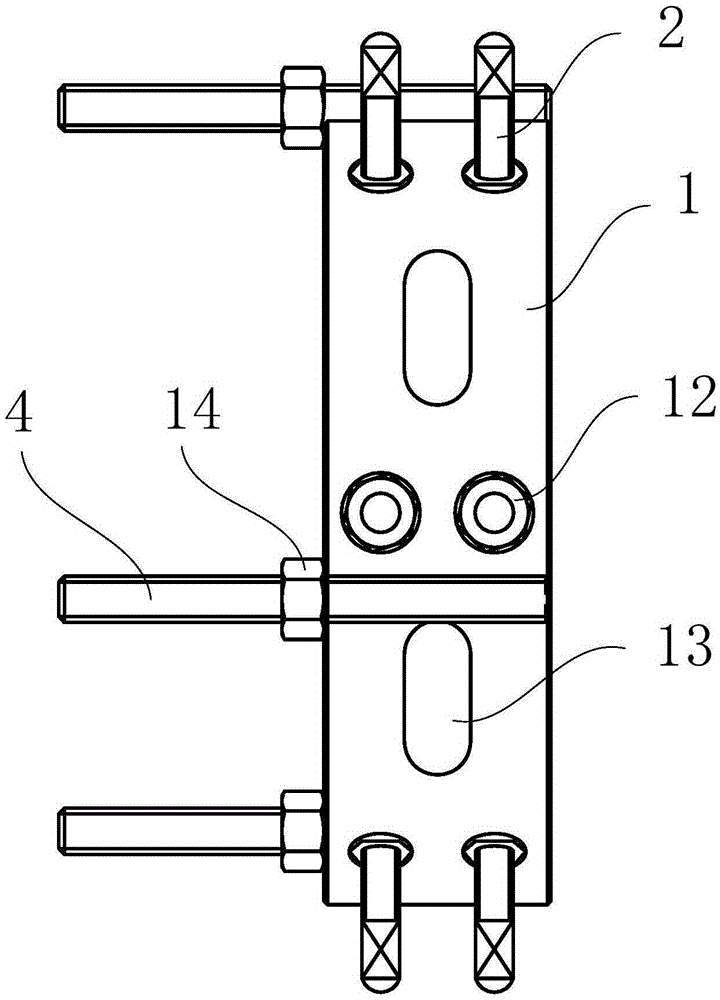

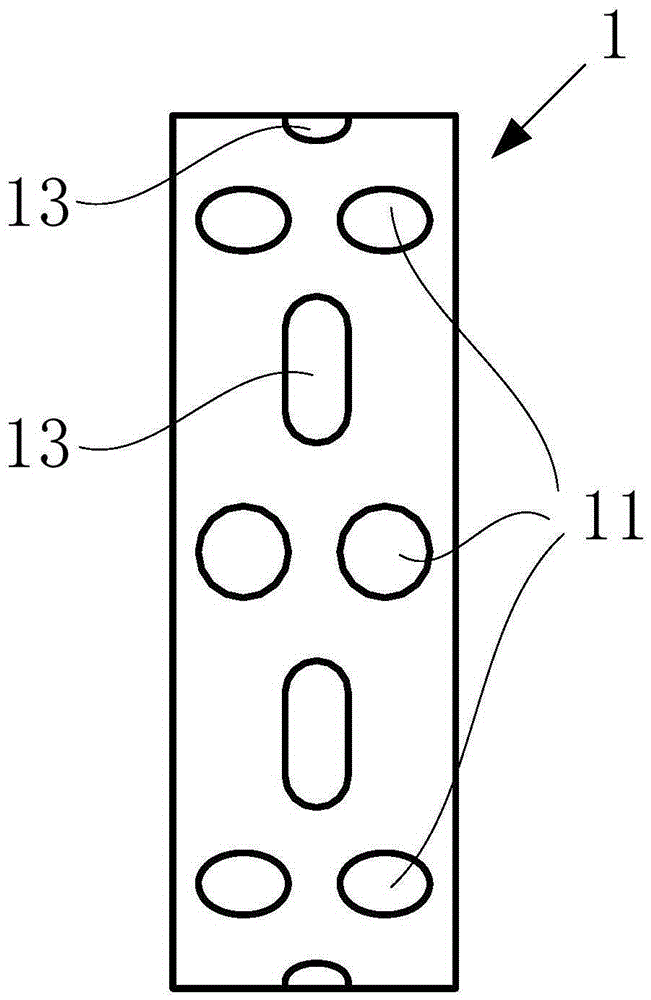

[0029] An embodiment of the present invention provides a correction device for correcting the shape of the delivery tube nozzle, see Figure 1-Figure 3 , the correction device includes: a sleeve 1 and at least one set of wire tops 2;

[0030] The surface of the sleeve 1 is provided with a plurality of installation holes 11, and each group of wire tops 2 includes at least three wire tops 2, and each wire top 2 included in each group of wire tops 2 corresponds to an installation hole 11, and each wire top 2 is respectively Threaded connection with respective corresponding mounting holes 11;

[0031] Each wire top 2 is arranged along the radial direction of the sleeve 1 , and one end of each wire top 2 is used to contact the nozzle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com