The thimble device with the head can be automatically swung

A head and thimble technology, which is applied to the accessories of the tool holder, tailstock/top, turning equipment, etc., can solve the problems of affecting the thimble bearing, unstable cutting process, and the inability to align the processed object with the center, so as to increase the service life , stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to be able to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the specification, the preferred embodiment shown in the accompanying drawings will be described in detail as follows:

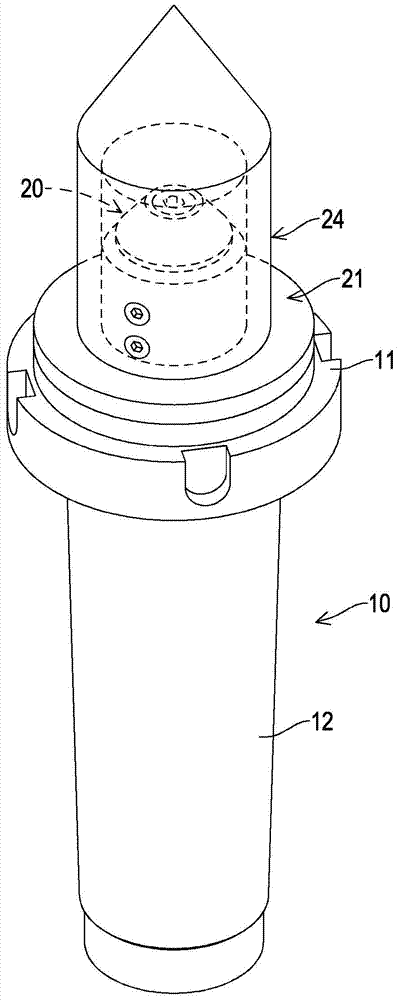

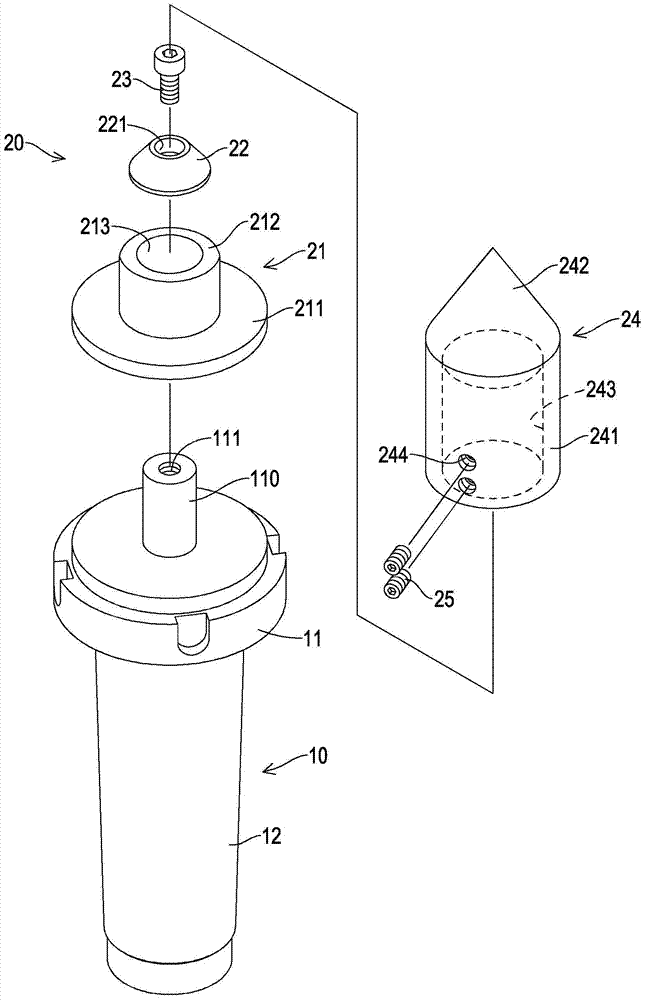

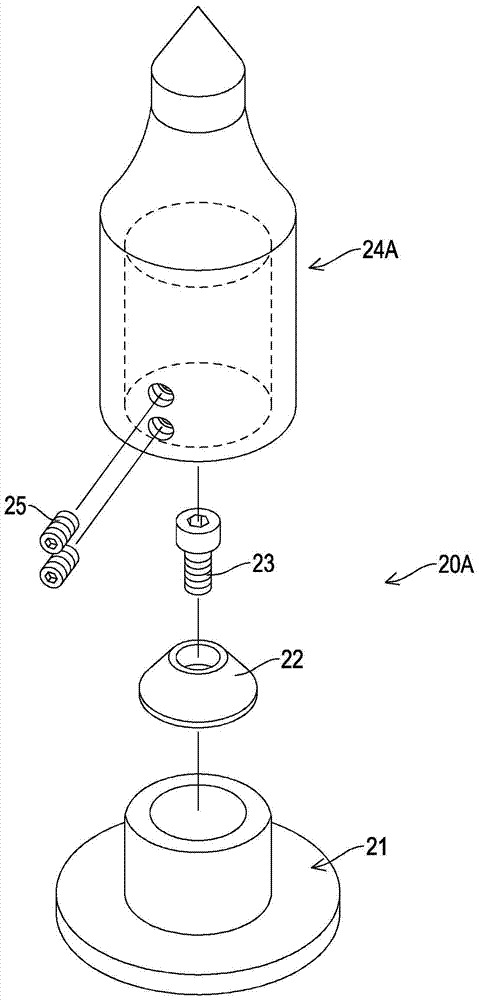

[0067] The present invention is a thimble device whose head can swing automatically, please refer to figure 1 and figure 2 The first preferred embodiment of the present invention comprises a top mandrel 10 and a head slider 20 .

[0068] Such as figure 1 and figure 2 As shown, the centering handle 10 is the centering handle of a fixed thimble, and is a handle body extending in the front and rear directions. A head 11 is formed at the top of the centering handle 10, and a head 11 is formed on the top of the head 11. A tapered shank 12 is formed on the lower side, and a coupling portion 110 is provided at the axial center on the top surface of the head 11. In this embodiment, the cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com