Hydraulic tensioning clamp

A technology of tightening clamps and hydraulic pressure, applied in the field of clamps for disc parts, can solve the problems of large ovality, thin positioning surface wall, easily deformed disc parts, etc., to achieve uniform force, stable precision, and lower production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples will further illustrate the hydraulic tensioning clamp and its usage method of the present invention.

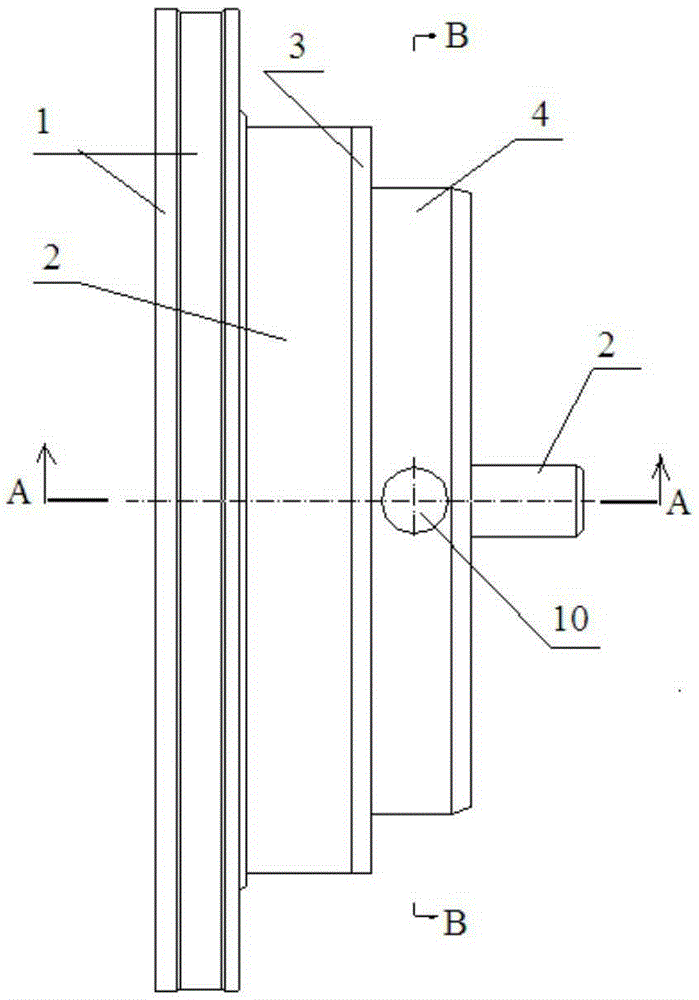

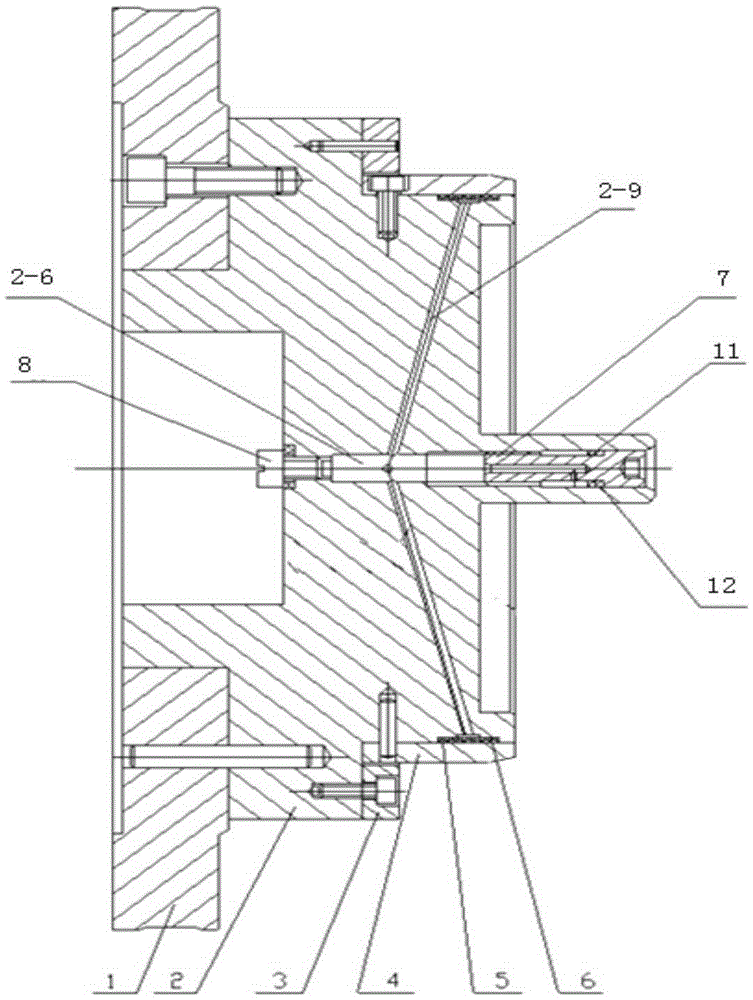

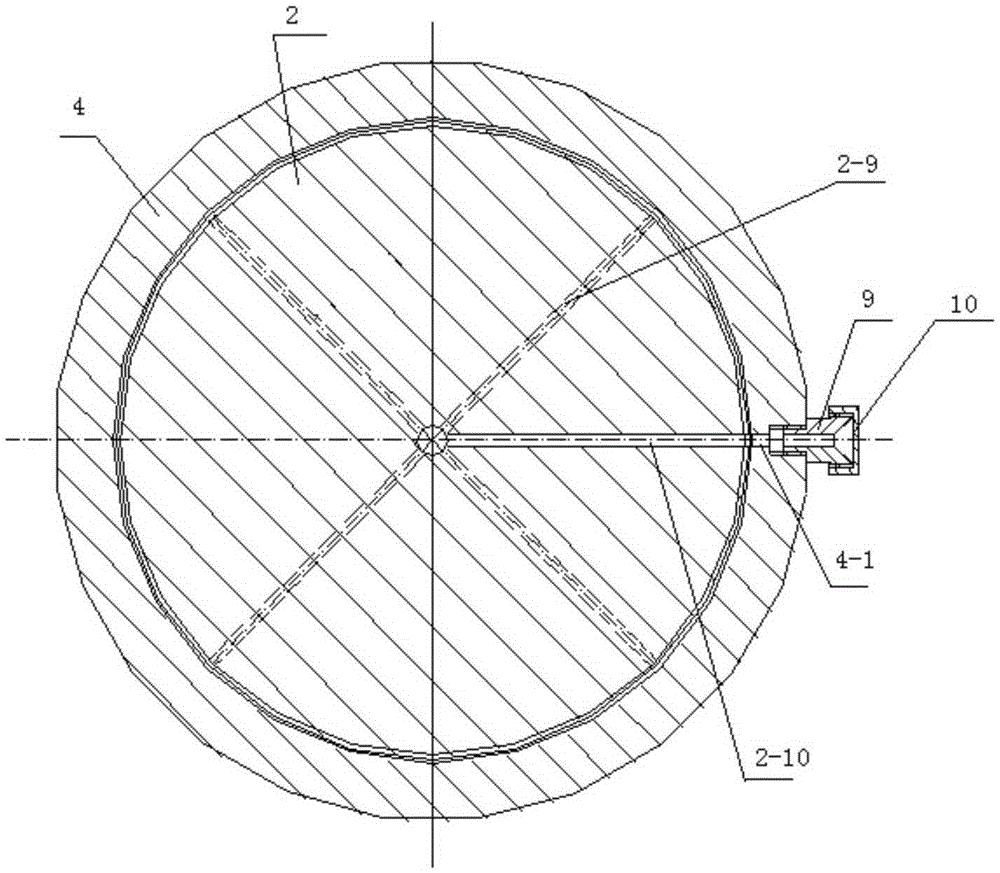

[0020] In this embodiment, the hydraulic tensioning fixture such as figure 1 , figure 2 , image 3 As shown, it includes a base 1 , a main body 2 , a support ring 3 , a positioning sleeve 4 , a spacer ring 5 , a sealing ring 6 , a screw plug 7 , an exhaust screw 8 , an oil cup 9 and a screw cover 10 .

[0021] The base 1 is as figure 2 As shown, the end faces of the left and right ends of the base are parallel to each other, and a central hole combined with the main body is provided, and the center line of the center hole is perpendicular to the end faces of the left and right ends of the base. The subject 2 as Figure 4 As shown, it is a stepped cylindrical platform, and from the left end to the right end of the stepped cylindrical platform are the first circular platform section 2-1, the second circular platform section 2-2, the third ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com