A kind of low dielectric microwave ferroelectric ceramic and its preparation method

A ferroelectric ceramic and microwave technology, applied in the field of microwave dielectric ceramics, achieves the effects of small dielectric constant, low microwave dielectric loss, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned low dielectric microwave ferroelectric ceramics comprises the following steps:

[0036] (1) BaO, ZnO and SiO 2 After mixing, carry out wet ball milling treatment, and pre-calcine at 1100°C after drying to obtain xBaO-yZnO-zSiO 2 Matrix ceramic powder;

[0037] (2) the above xBaO-yZnO-zSiO 2 The base ceramic powder is subjected to wet ball milling treatment, after being dried, polyvinyl alcohol (PVA) is added to granulate, and after being pressed into tablets, it is sintered to obtain a microwave ferroelectric material.

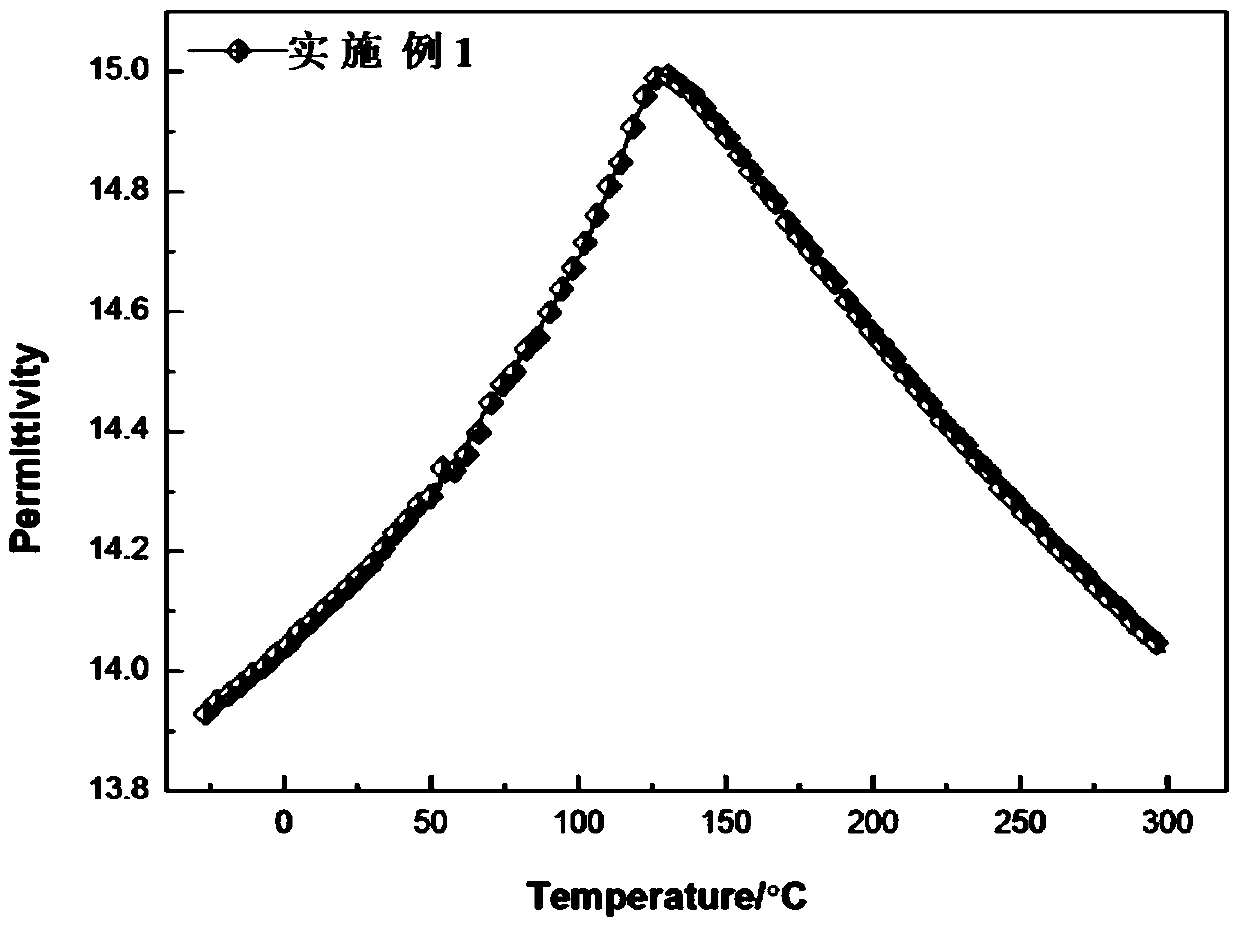

Embodiment 1

[0039] Embodiment 1: The preparation chemical formula is BaO-ZnO-SiO 2 Low dielectric microwave ferroelectric ceramics;

[0040] (1) Using analytically pure BaO, ZnO and SiO 2 Powder is used as raw material, after mixing according to the ratio of 1:1:1, zirconium balls are used as the medium and deionized water is used as the solvent, and the powder is mixed and stirred for 3 hours with a ball mill at a speed of 360r / min; the obtained slurry is dried and placed in the Pre-fired at 1100°C for 3 hours to obtain matrix ceramic powder;

[0041] (2) The matrix ceramic powder obtained is ball-milled again, and after drying, 3wt% polyvinyl alcohol (PVA) binder is added in the dry powder to granulate, and it is pressed under the pressure of 100MPa into a thickness and a diameter ratio of Cylindrical green samples of 0.4 to 0.6;

[0042] (3) After debinding the above green sample at a temperature of 550°C, raise the temperature to 1200°C at a rate of 5°C / min, and sinter in air for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com