Oil-mist spraying device for fibers

A fiber and oil agent technology, applied in the field of fiber oil spray device, can solve problems such as affecting the fiber processing quality and insufficient uniformity of fiber oil mist, and achieve the effect of improving processing quality and uniform oil mist spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

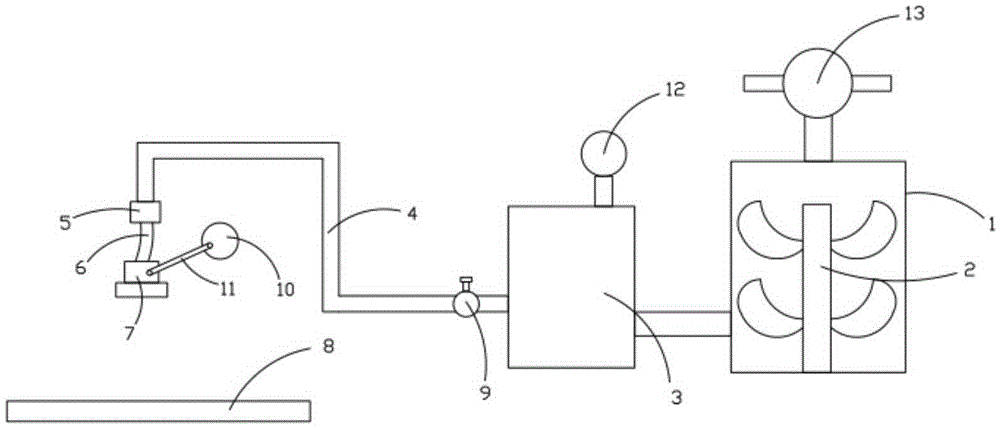

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, the present invention discloses a fiber oil spray device, comprising a sealed mixing tank 1 for mixing oil and water, a stirring assembly 2 arranged in the sealed mixing tank 1, and the sealed mixing tank 1 The connected pressurized tank 3, the conveying pipeline 4 connected with the pressurized tank 3, the control switch 5 arranged at the water outlet end of the conveying pipeline 4, the mist connected with the control switch 5 through the connecting hose 6 The atomization nozzle 7, the driving mechanism for controlling the left and right swing of the atomization nozzle 7, the conveyor belt 8 for transporting fibers arranged under the atomization nozzle 7, and the pressure adjustment switch 9 is also arranged on the transportation pipeline 4 , the drive mechanism includes an eccentric wheel 10 driven by a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com