Wood shutter blade

A shutter and blade technology, applied in decorative arts, shading screens, ventilation layout, etc., can solve the problems of paint pollution, reduced utilization rate of wooden blades, and unreachable blades, so as to solve the difficulty of obtaining materials, improve the utilization rate, and match the the effect of coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

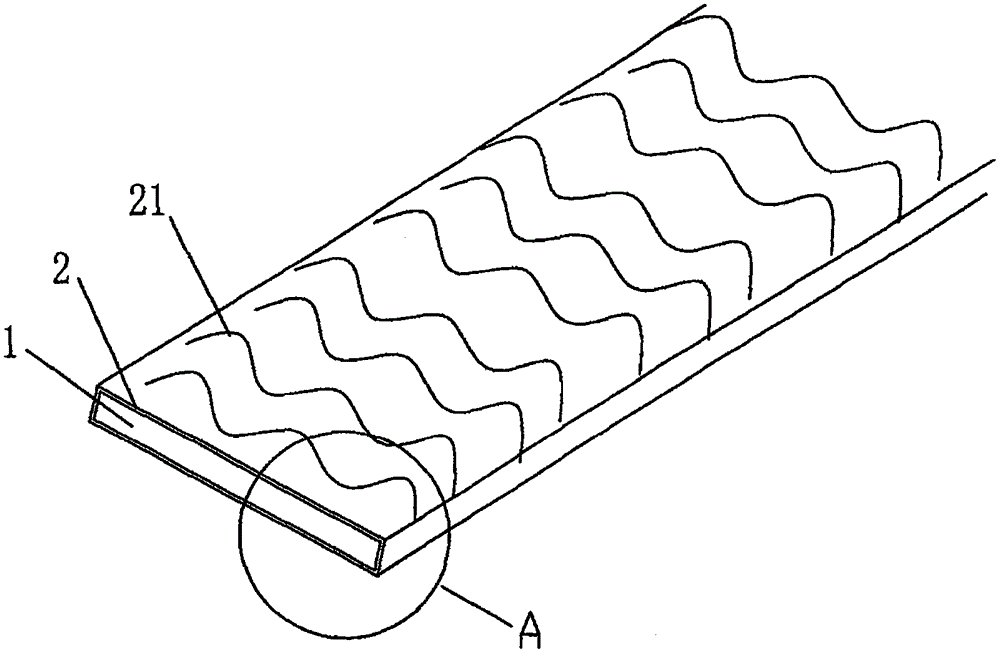

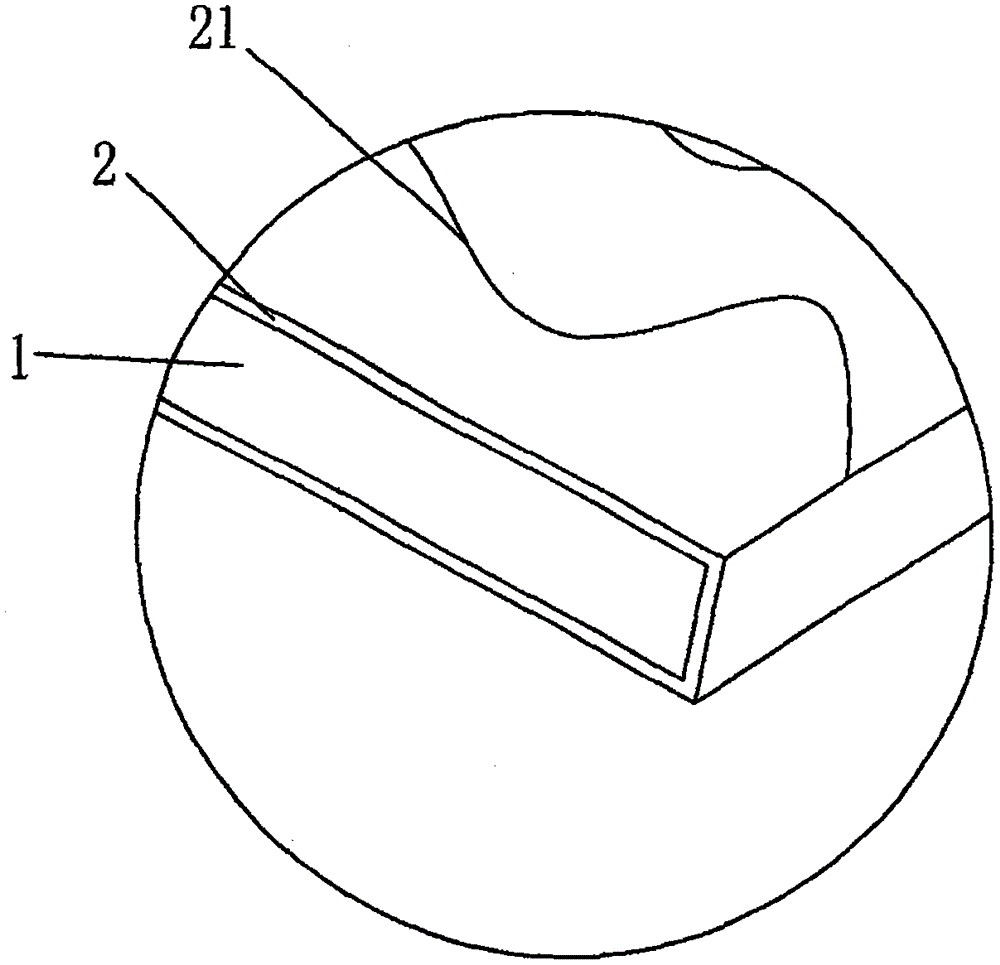

[0009] as attached figure 1 As shown, a wooden shutter blade is mainly composed of a blade main body 1 and a printing layer 2 on the outer surface of the main body 1 . The blade main body 1 is processed by wood material, and the printing layer 2 on the surface is formed with patterns of various textures.

[0010] The texture in this embodiment is beech wood grain 21 similar to scales.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap