One Mode Continuously Variable Transmission With Low Loss Configuration

A technology of continuously variable transmissions and transmissions, which is applied to vehicle gearboxes, components with teeth, transmission devices, etc., and can solve problems such as complex layout and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The following description is merely exemplary in nature and is not intended to limit the disclosure, application, or uses.

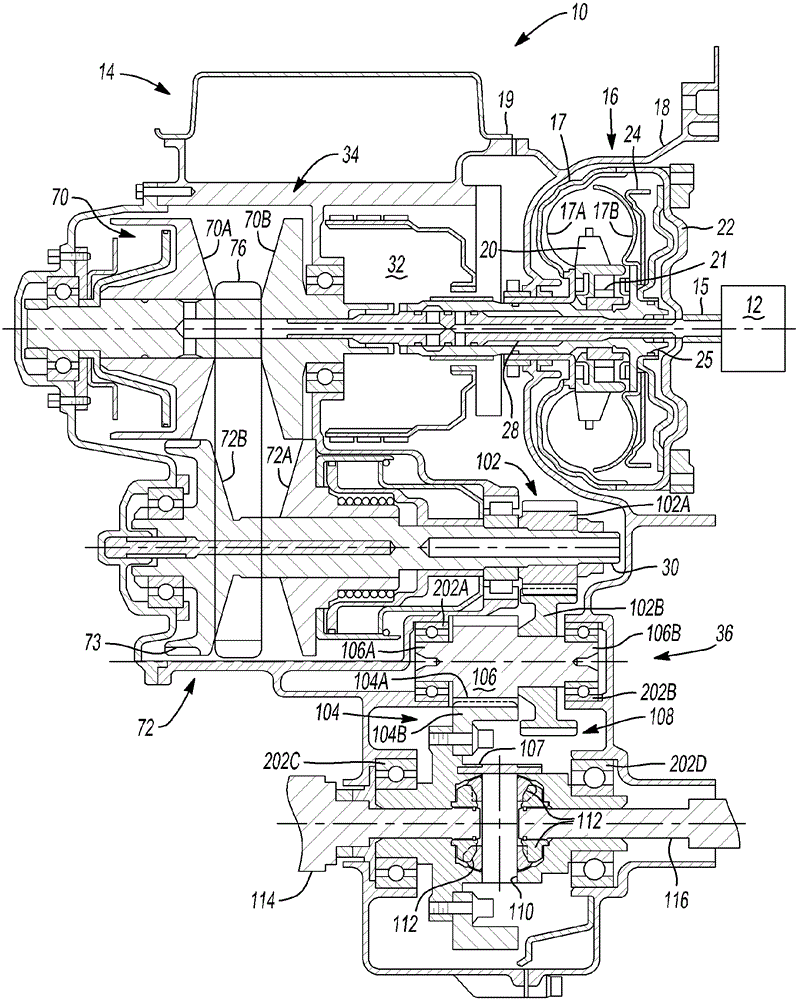

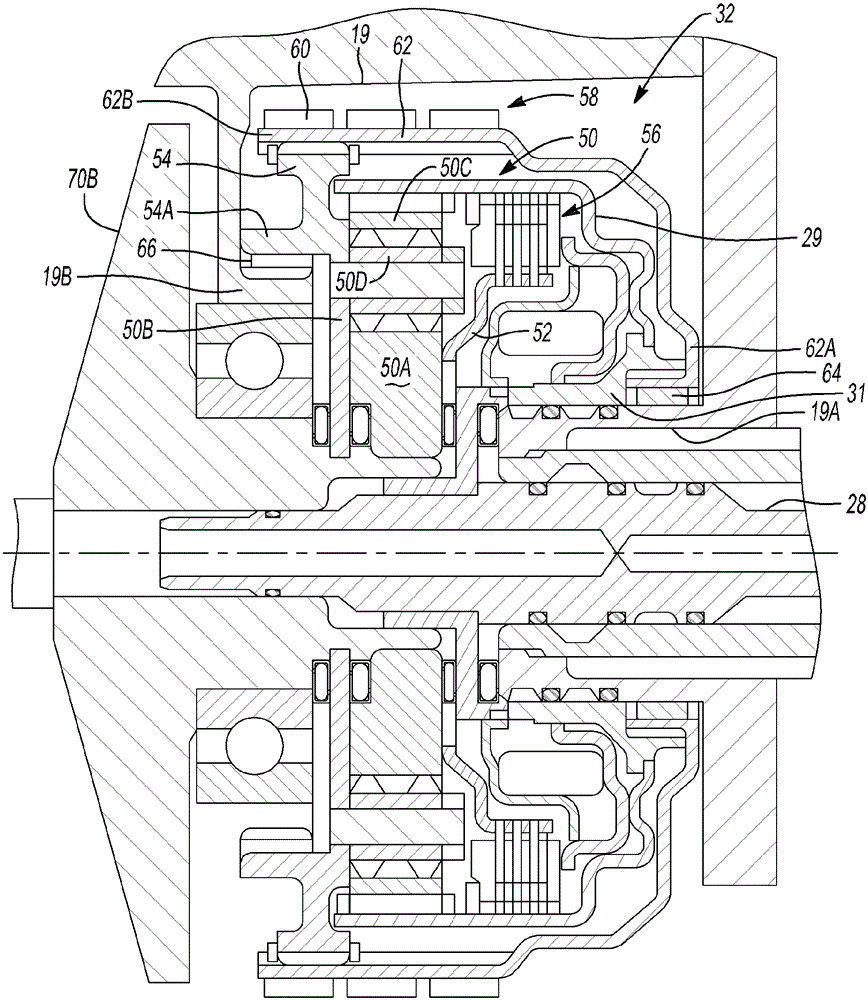

[0073] refer to figure 1 and 2 , a powertrain for a motor vehicle is generally indicated by reference numeral 10 . The powertrain 10 generally includes an engine 12 interconnected with a transmission 14 . Engine 12 may be a conventional gasoline, diesel, or flex-fuel internal combustion engine, a hybrid engine, or an electric motor, or any other type of motive force without departing from the scope of the present disclosure. The engine 12 includes an engine output shaft 15 that supplies drive torque to a transmission 14 through a torque converter 16 .

[0074] The torque converter 16 includes a toroid 17 contained within a torque converter housing 18 . Torque converter housing 18 is coupled to transmission housing 19 . The toroidal body 17 includes a pump 17A, a stator 20 connected to the transmission housing 19 by a one-way clutch 21 to prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com