Thin tube dedicated fixture under action of axial and internal pressure composite load

A composite load, special fixture technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of limiting the abundance of test plans, unable to withstand excessive loads, etc., to achieve good sealing, reasonable design, easy test operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

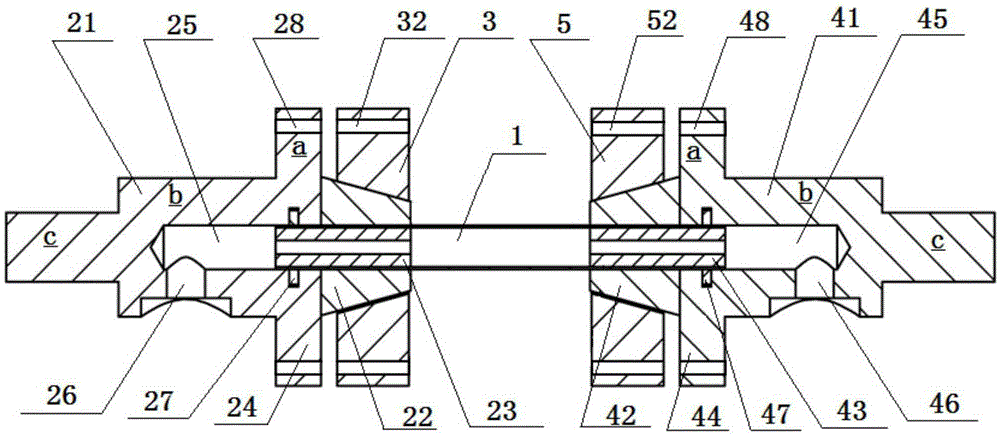

[0030] The specific clamp for thin tubes under the composite load of axial and internal pressure of the present invention will be described in detail below with reference to the embodiments and drawings.

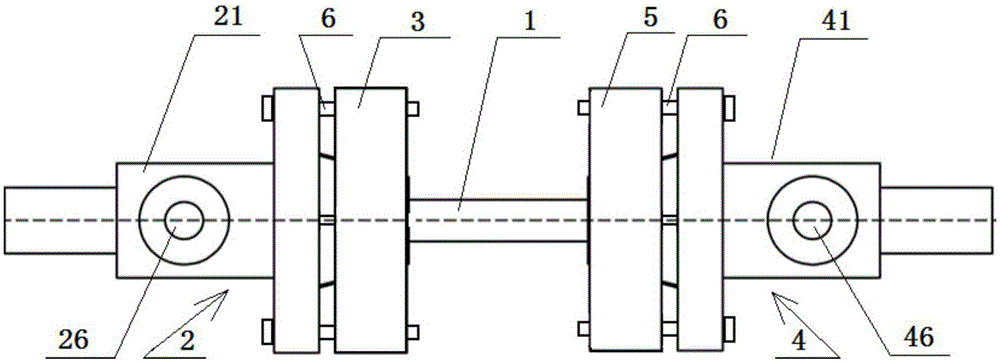

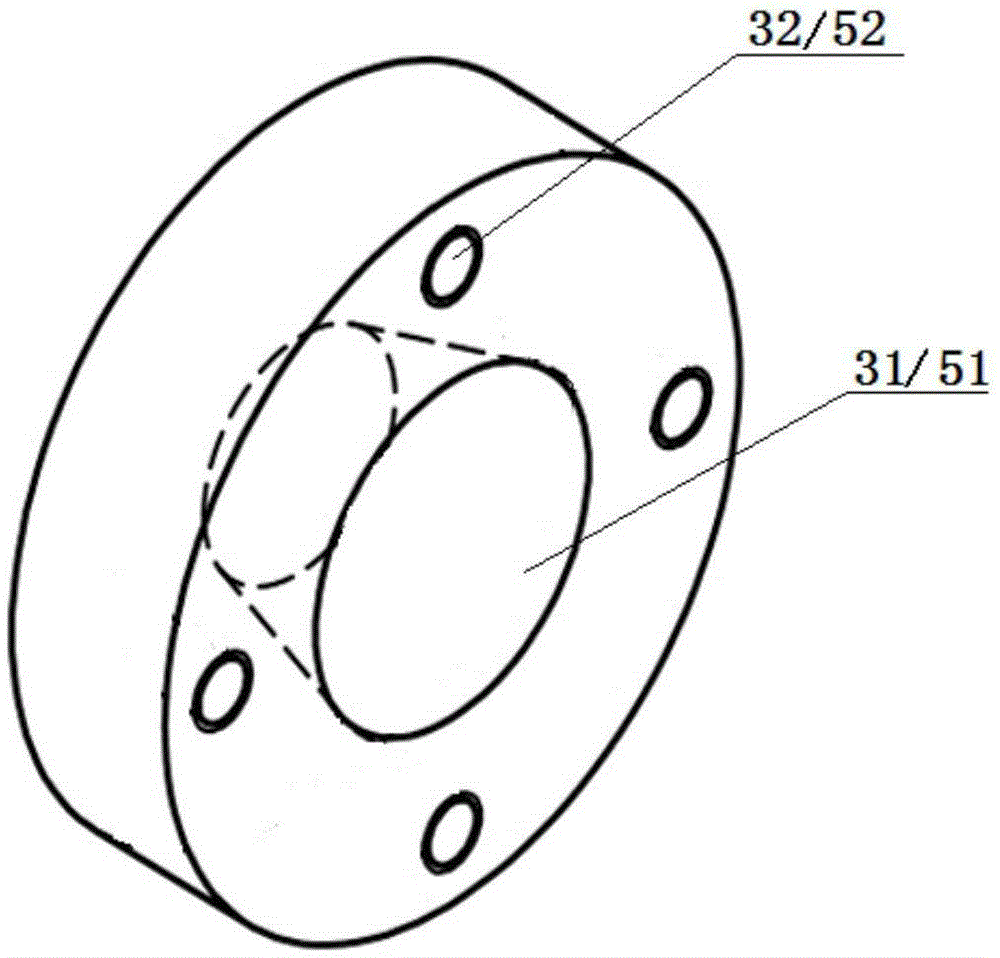

[0031] Such as figure 1 As shown, the special clamp for thin tubes under the combined axial and internal pressure load of the present invention includes: a front end clamping mechanism 2, which is connected to the measured thin-walled round tube 1 through a front flange 3, and is used to clamp the measured thin-walled round tube 1, and introduce hydraulic oil or air pressure to the measured thin-walled circular tube 1; the rear end clamping mechanism 4, connects the measured thin-walled circular tube 1 through a rear flange 5, and is used to clamp the rear port of the measured thin-walled circular tube 1 , and make sure to seal the hydraulic oil outlet end of the thin-walled circular tube 1 under test. If the hydraulic oil is introduced from the front end oil port of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com