Integrated operating rod of outdoor grounding knife switch

A technology of grounding knife switch and operating lever, which is applied in the field of operating levers, can solve the problems of waste of operating time, easy rusting of operating levers, and lack of versatility, and achieve the effect of saving time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

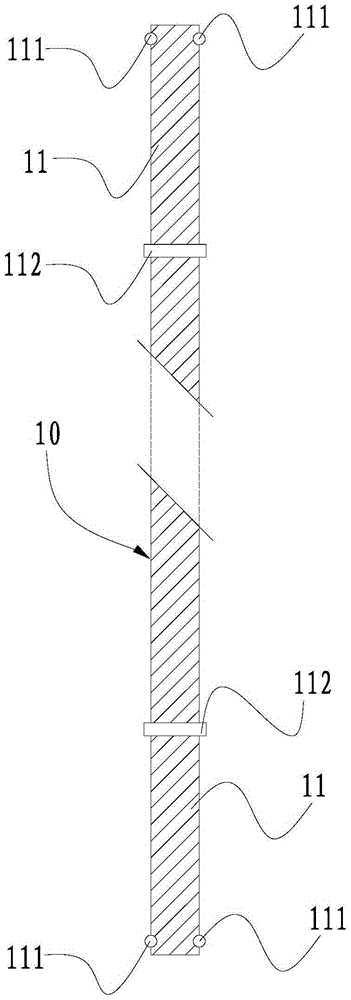

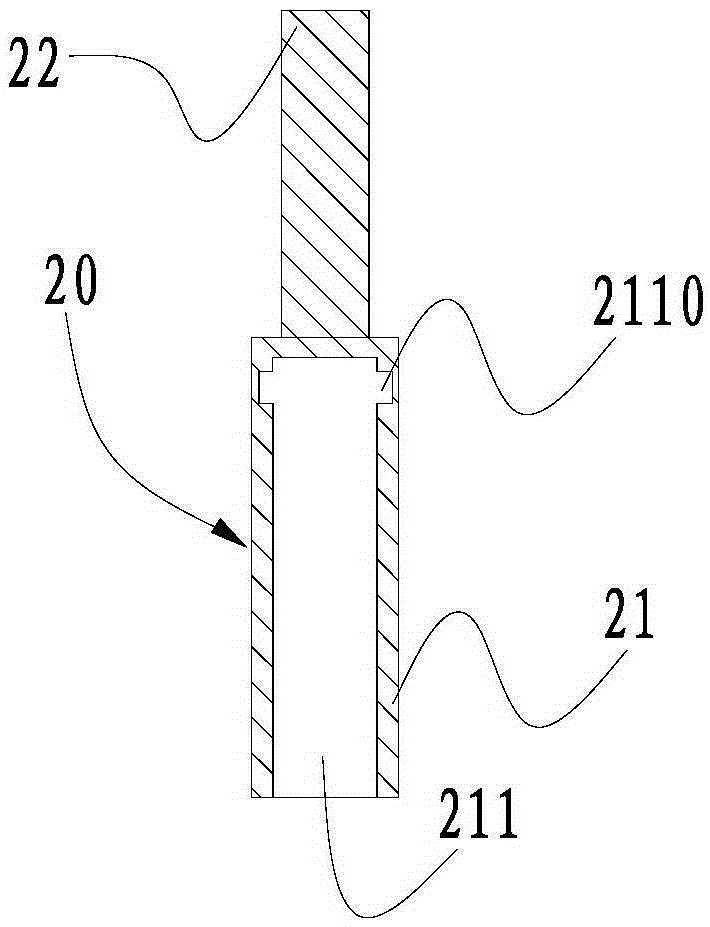

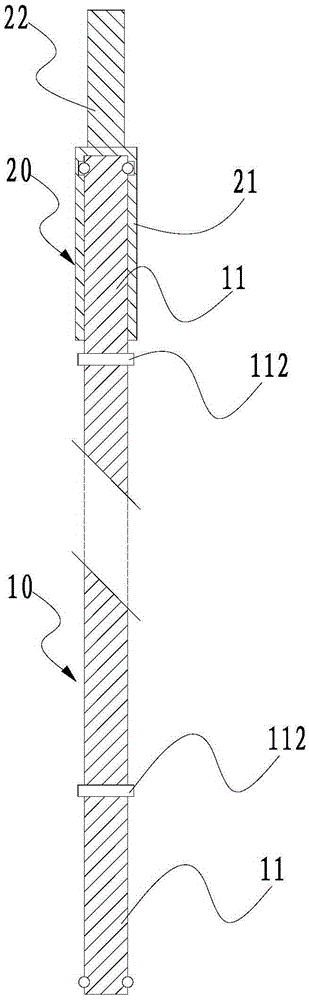

[0015] see Figure 1 to Figure 3 , the one-in-one outdoor grounding knife switch operating rod includes a base rod 10 and an adapter part 20 detachably sleeved on the end of the base rod 10, the adapter part 20 includes a sleeve part 21 and an actuating rod 22, the sleeve One end of the sleeve part 21 is closed and the other end is provided with a socket hole 211. The actuating rod 22 is arranged on the top of the closed end of the sleeve part 21. The inner diameter of the socket hole 211 corresponds to the outer diameter of the end of the basic rod 10. The actuating rod 22 The outer diameter is set corresponding to the hole diameter of the grounding knife switch actuating hole (not shown in the figure), and the base rod 10 cooperates with the adapter part 20 through the sleeve part 21, so that the grounding knife switch is linked by the actuating rod 22 of the adapter part 20 (figure Not shown) do the split action.

[0016] see Figure 1 to Figure 3 , both ends of the basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com