Layered transparent conductive oxide thin films

A technology of oxide film and conductive oxide, which is applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of increasing process complexity, and achieve the elimination of Si growth problem, enhanced haze, low The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

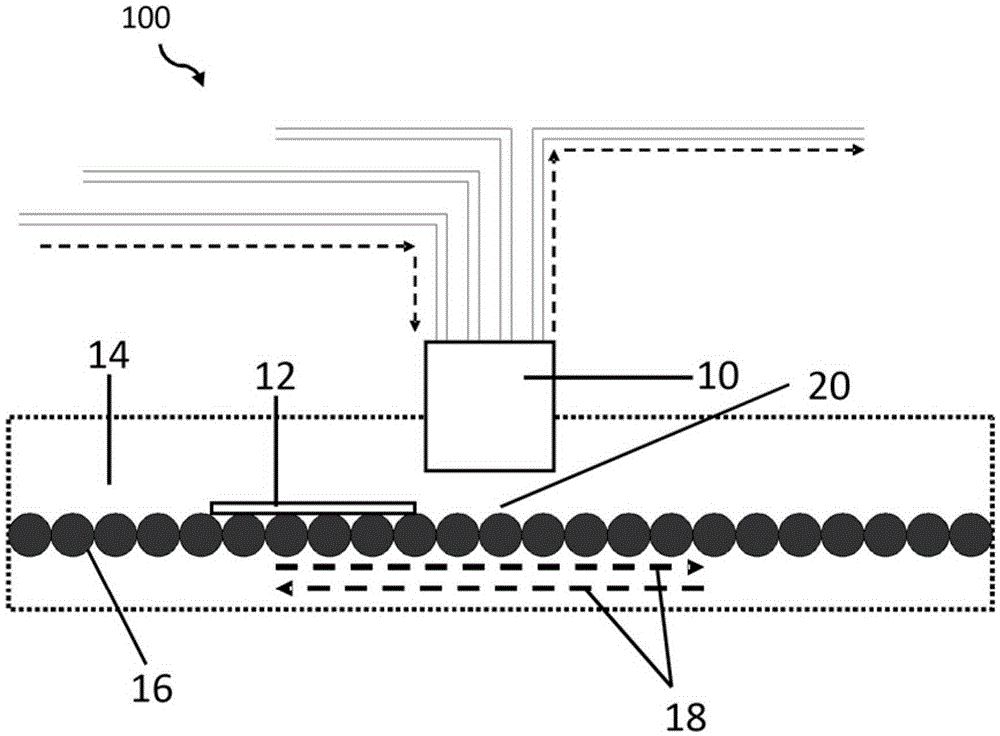

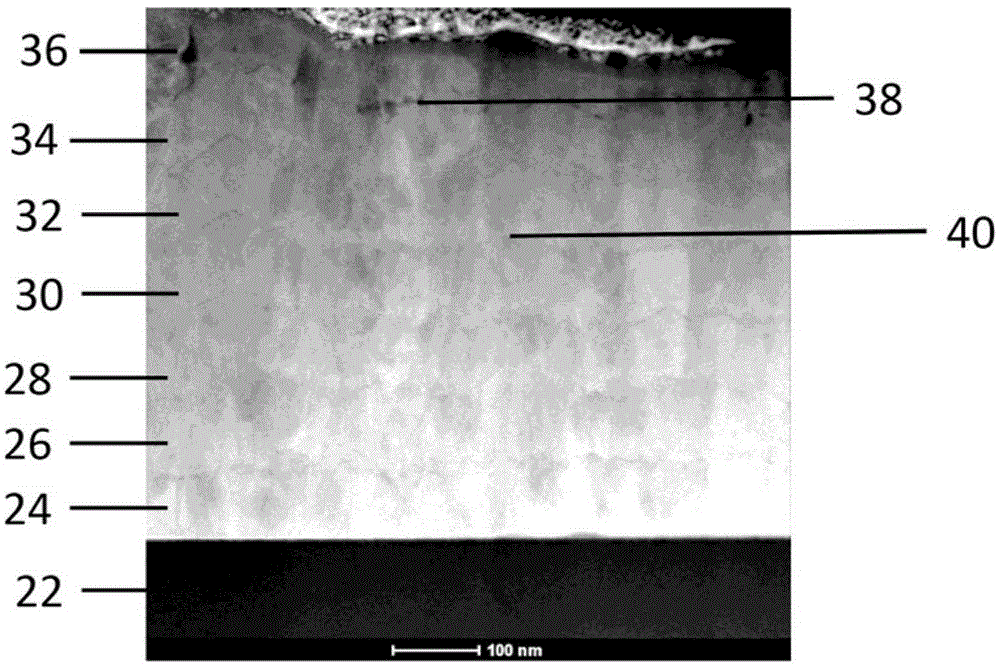

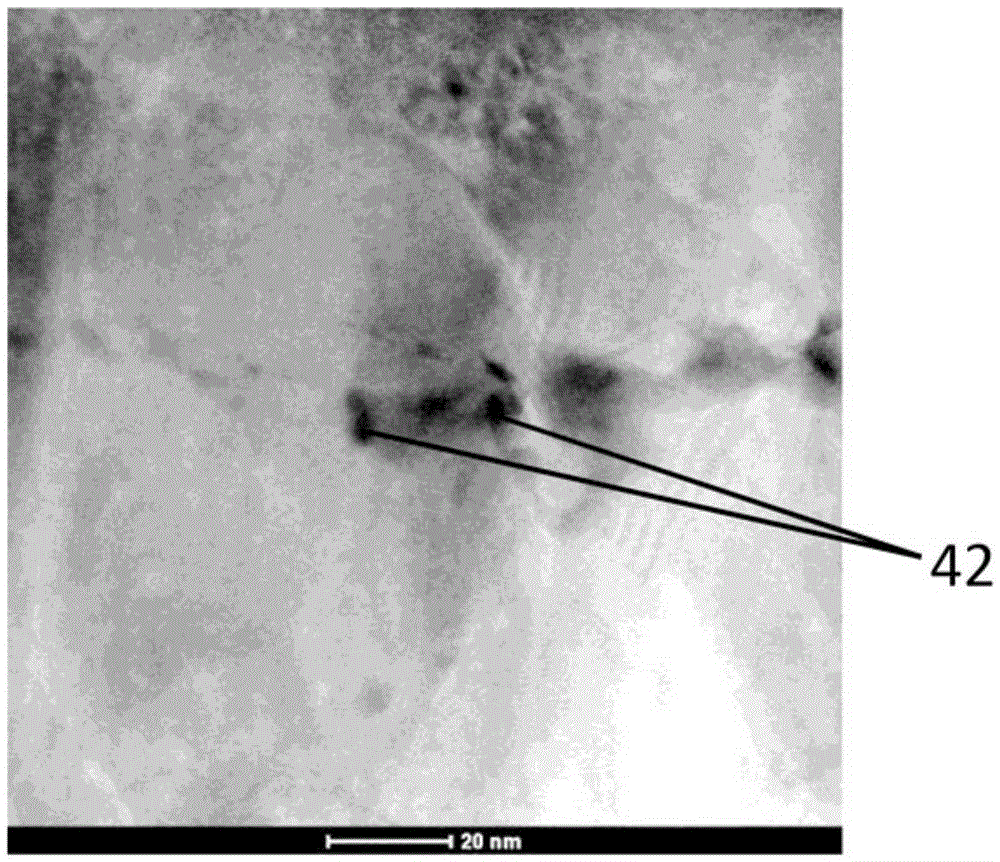

[0022] Reference will now be made in detail to one or more presently preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0023] As used herein, the term "substrate" can be used to describe either a substrate or a superstrate, depending on the photovoltaic cell configuration. For example, a substrate is a top plate if the substrate is on the light incident side of the photovoltaic cell when assembled to the photovoltaic cell. The overhead plate may be protected from impact and environmental degradation by photovoltaic material while allowing transmission of the appropriate wavelengths of the solar spectrum. Additionally, a plurality of photovoltaic cells may be arranged into a photovoltaic module. Photovoltaic devices can be described as cells, modules, or both.

[0024] Where numerical ranges are recited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com