Milk sterilizer

A sterilizer, milk technology, applied in the preservation of milk, dairy products, applications, etc., can solve the problems of complex process and high cost, and achieve the effect of simplifying the sterilization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

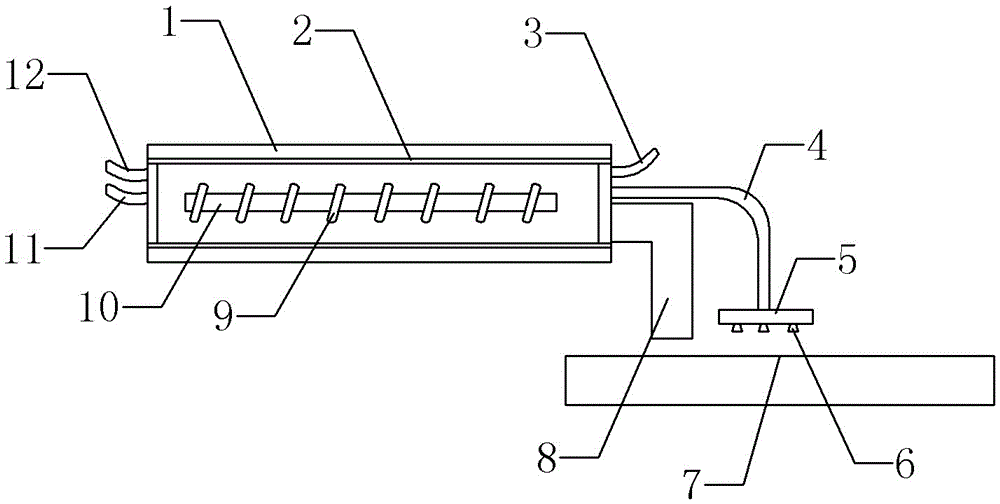

[0011] The reference signs in the drawings of the description include: sterilization cylinder 1, heat insulation layer 2, steam outlet pipe 3, liquid outlet pipe 4, mounting plate 5, liquid outlet nozzle 6, conveyor belt 7, bottle outlet pipe 8, sterilization pipe 9, Rotating shaft 10, liquid inlet pipe 11, steam inlet pipe 12.

[0012] The embodiment is basically as attached figure 1 As shown: the milk sterilizer of this embodiment includes a horizontal sterilization cylinder 1, and a layer of heat insulation layer 2 is arranged on the inner wall of the sterilization cylinder 1. A horizontal rotating shaft 10 is arranged in the sterilization cylinder 1, and a sterilizing tube 9 is spirally wound on the rotating shaft 10. When the rotating shaft 10 rotates, the sterilizing tube 9 and the rotating shaft 10 form a screw conveyor for conveying feeding bottles.

[0013] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com