Butyl rubber polypropylene thermoplastic elastomer capable of being sterilized by irradiation and preparation method of butyl rubber polypropylene thermoplastic elastomer

A thermoplastic elastomer and butyl rubber technology, which is applied in the field of butyl rubber polypropylene thermoplastic elastomer and its preparation, can solve the problems of deterioration of PP mechanical properties, loss of use function, aggravation of aging phenomenon, etc. Safety and effect of improving radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

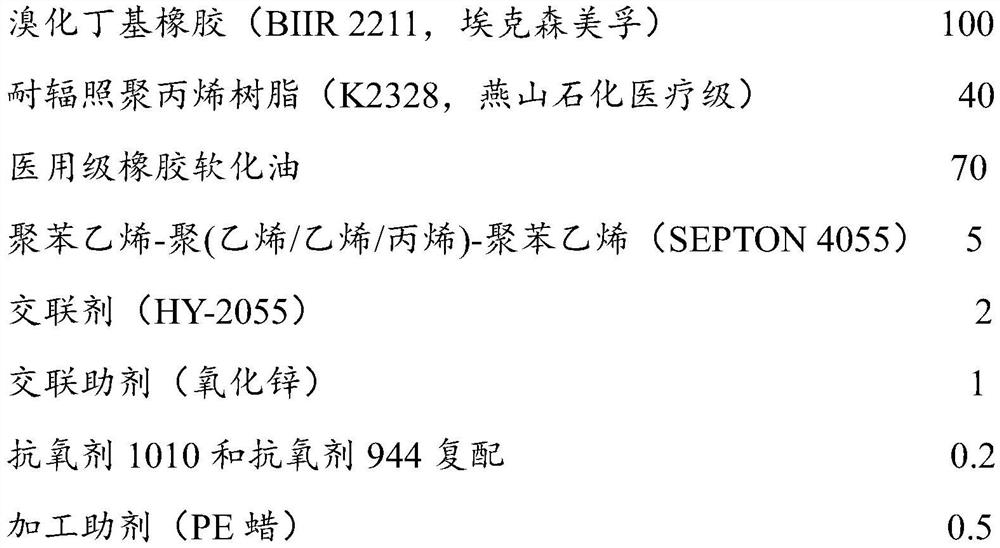

[0031] Embodiments 1-3: butyl rubber polypropylene thermoplastic elastomer material capable of irradiation sterilization and its preparation method

[0032] The preparation method of the butyl rubber polypropylene thermoplastic elastomer material which can be sterilized by radiation specifically comprises the following steps:

Embodiment 1

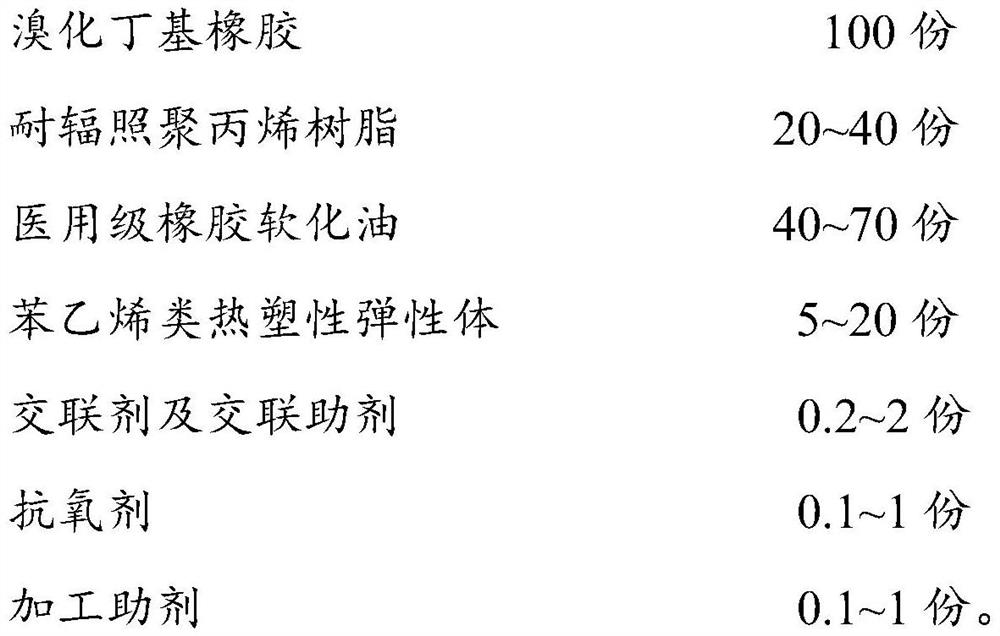

[0035] The butyl rubber polypropylene thermoplastic elastomer formula that can be sterilized by radiation is composed as follows, and each component is expressed in parts by weight.

[0036]

[0037] Preparation Process:

[0038] (1) Rubber and plastic pre-mixing: mix bromobutyl rubber, radiation-resistant polypropylene resin, medical grade rubber softening oil, styrene thermoplastic elastomer, antioxidant, and other additives according to their respective weight parts Finally, put it into the internal mixer, the temperature of the internal mixer is 165 °C, and internal mixer for 30 minutes, so that the rubber and resin are fully mixed and uniform, and sent into the single-screw extruder for granulation, so as to obtain the pre-mixed intermediate.

[0039] (2) Dynamic vulcanization: put the pre-mixed intermediate, cross-linking agent, and cross-linking auxiliary agent into a twin-screw extruder in a certain proportion for dynamic vulcanization and granulation. The screw spe...

Embodiment 2

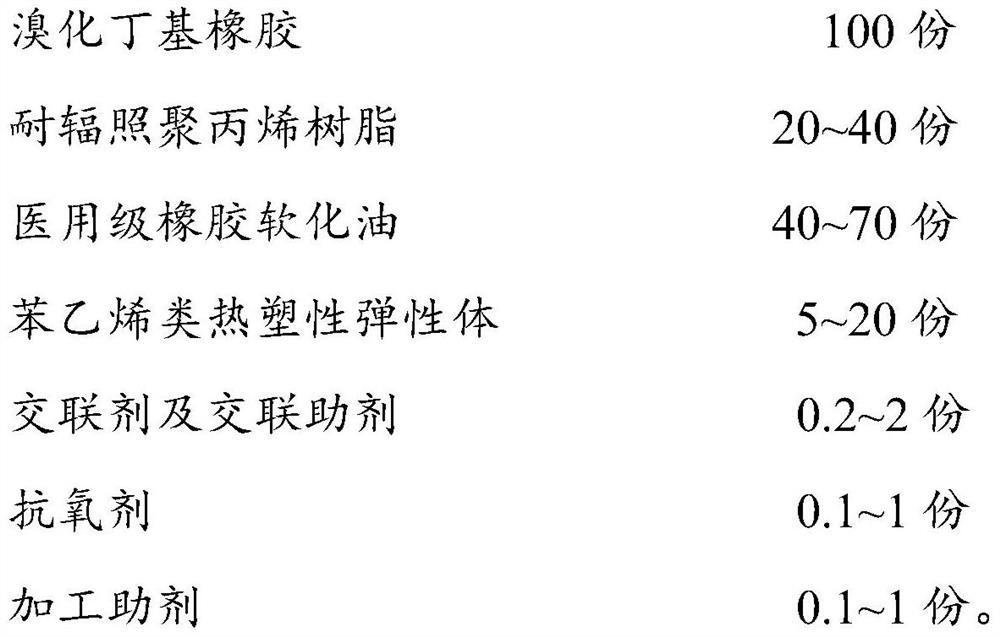

[0041] The butyl rubber polypropylene thermoplastic elastomer formula that can be sterilized by radiation is composed as follows, and each component is expressed in parts by weight.

[0042]

[0043] Preparation Process:

[0044](1) Rubber and plastic pre-mixing: mix bromobutyl rubber, radiation-resistant polypropylene resin, medical grade rubber softening oil, styrene thermoplastic elastomer, antioxidant, and other additives according to their respective weight parts Finally, put it into the internal mixer, the temperature of the internal mixer is 165 °C, and internal mixer for 30 minutes, so that the rubber and resin are fully mixed and uniform, and sent into the single-screw extruder for granulation, so as to obtain the pre-mixed intermediate.

[0045] (2) Dynamic vulcanization: put the pre-mixed intermediate, cross-linking agent, and cross-linking auxiliary agent into a twin-screw extruder in a certain proportion for dynamic vulcanization and granulation. The screw spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com