Off-line sterilization method of a respirator on a buffer tank

An offline sterilization and respirator technology, applied in the field of filling buffer tanks, can solve the problems of inability to completely sterilize and delay the production process, and achieve the effect of saving time, improving production efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

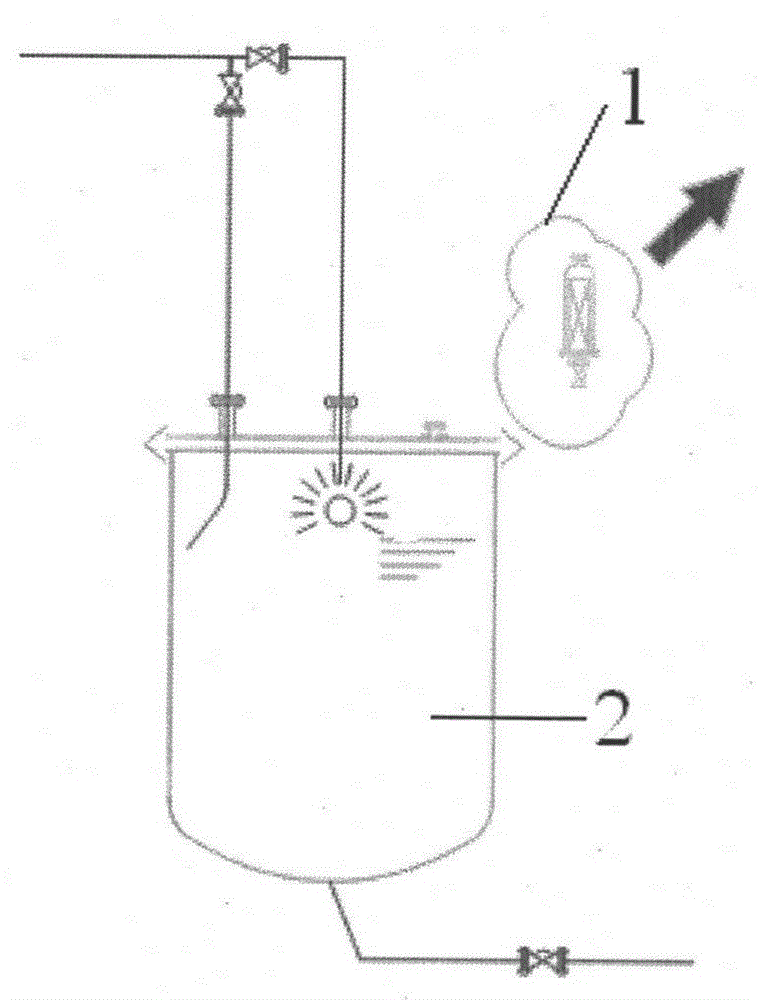

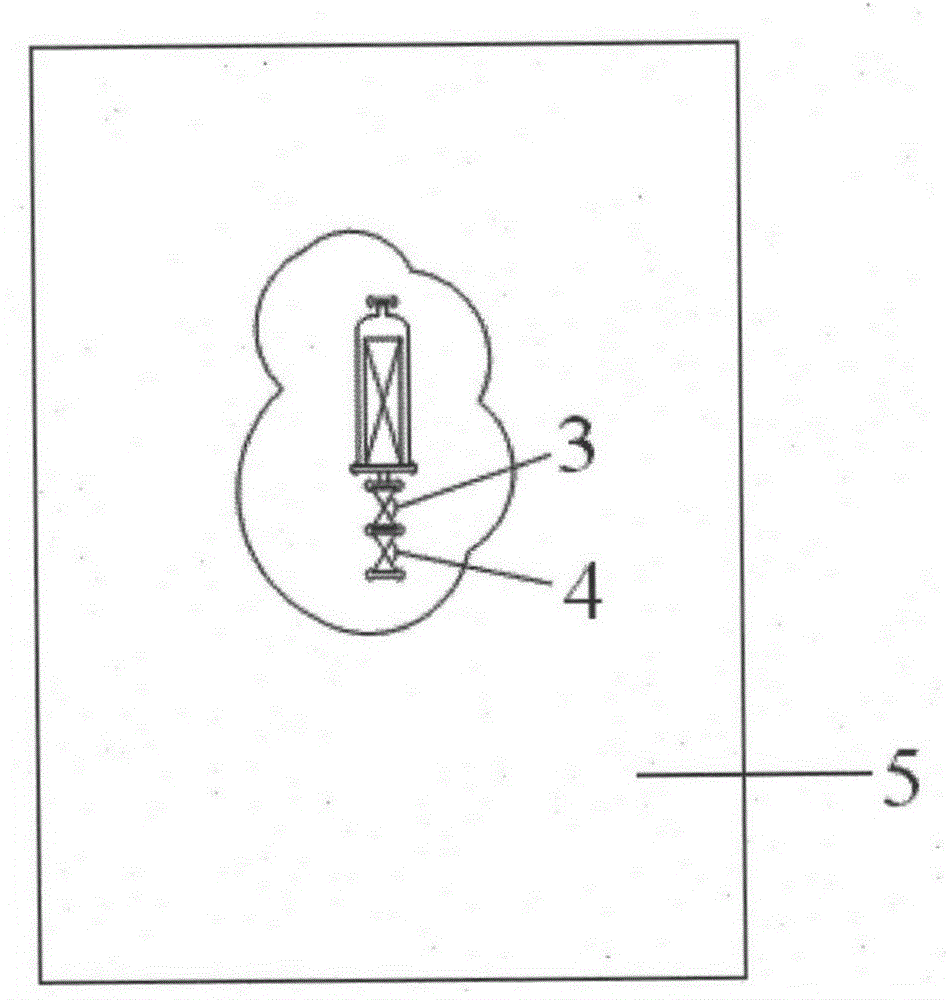

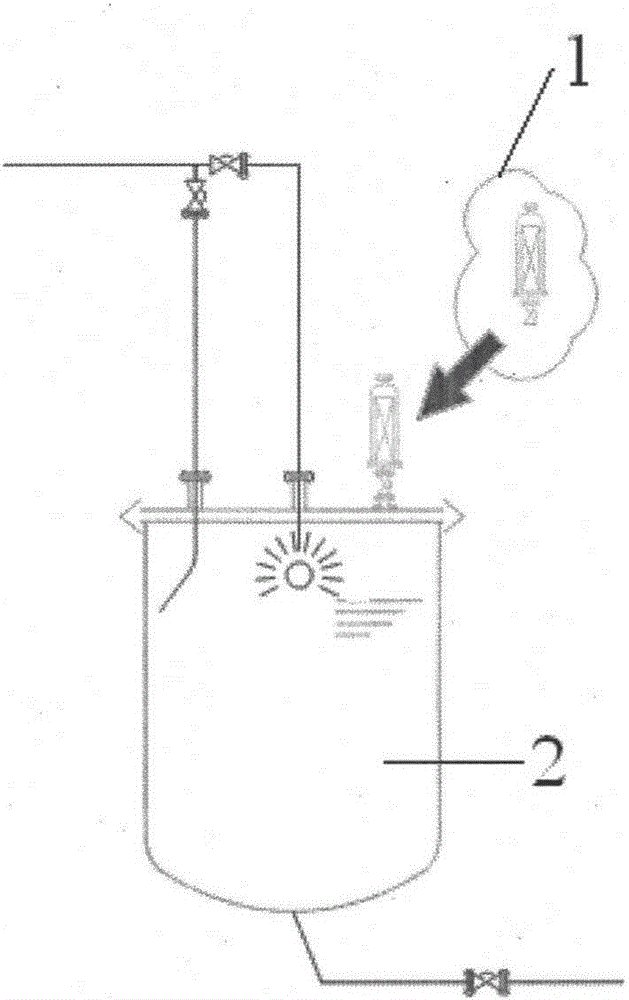

[0023] Figure 1 ~ Figure 3 The schematic diagram of the off-line sterilization method process of the respirator on the buffer tank provided by the present invention, the respirator is installed on the respirator port on the buffer tank of the filling machine, and the respirator hand valve is housed below the respirator, and the buffer tank The offline sterilization method for respirators on the Internet consists of the following 3 steps:

[0024] Step 1: Combine figure 1 , remove the respirator and respirator hand valve combination 1, the respirator port on the buffer tank 2 is sealed with a stuffy plate, and then the buffer tank 2 can be automatically sterilized online. The online sterilization of the buffer tank refers to the online sterilization of the buffer tank through internal steam circulation after the respirator is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com