Base Assembly for Floor Cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Hereinbelow, an exemplary embodiment of the present invention will be described with reference to accompanying drawings.

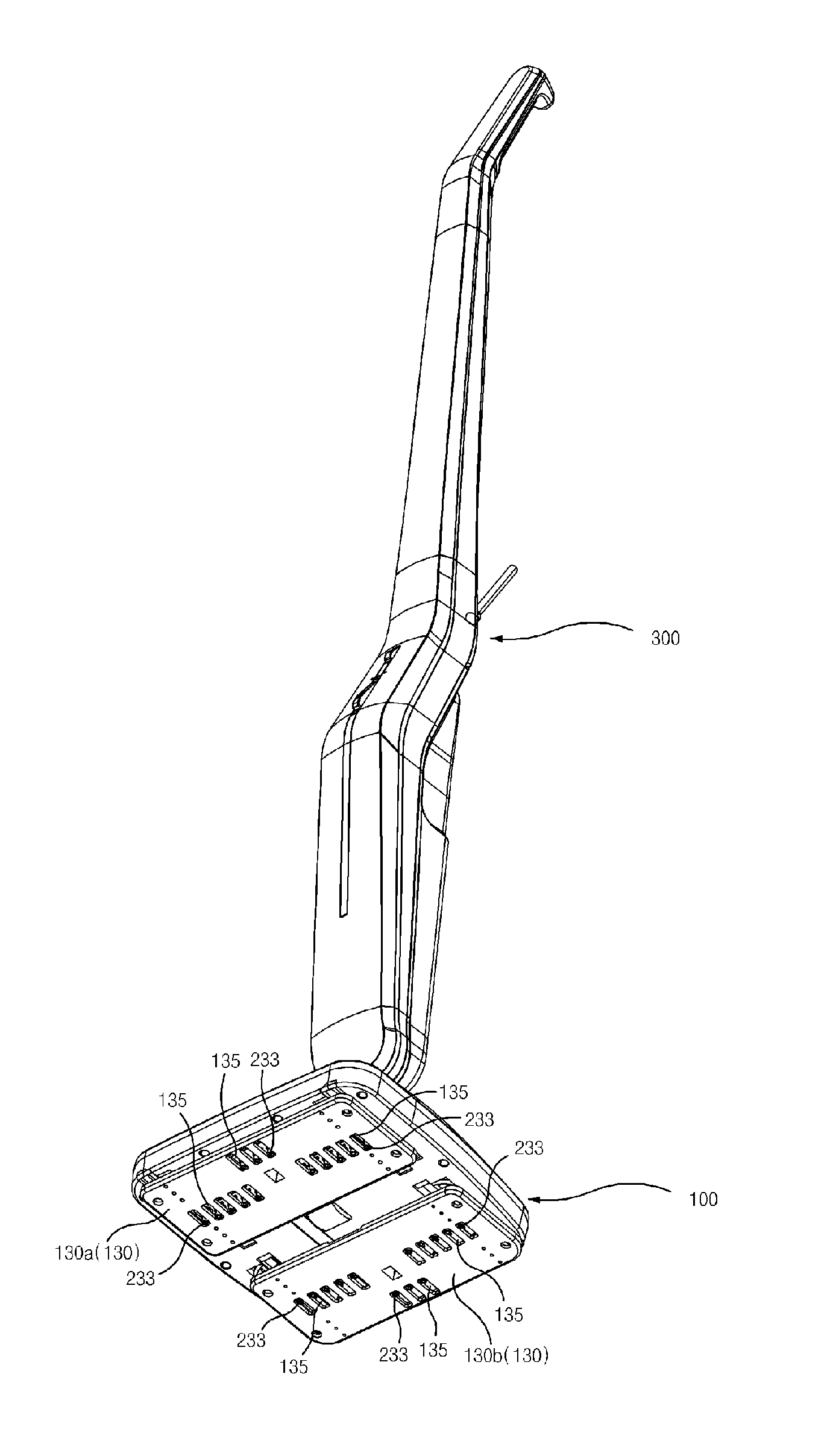

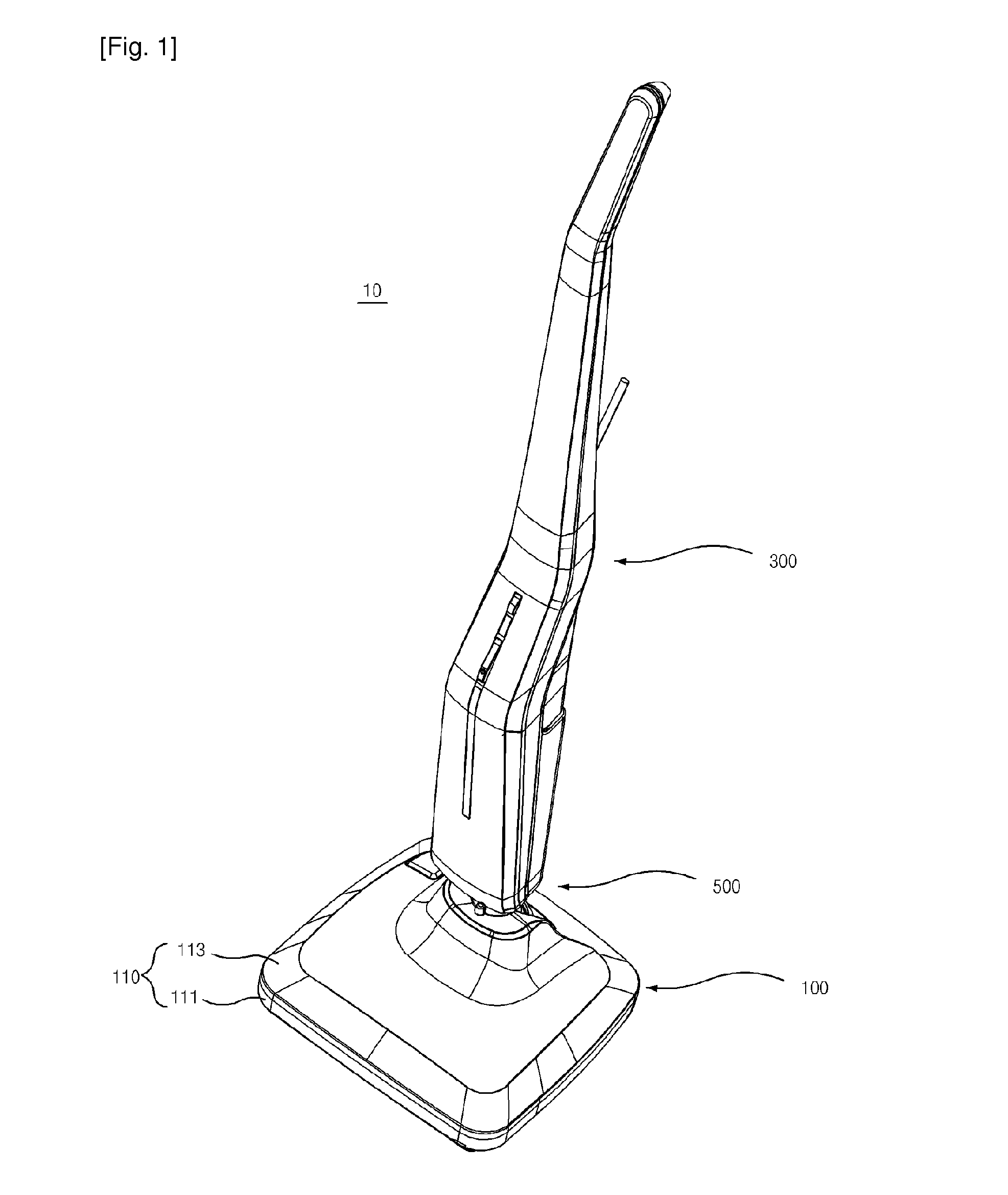

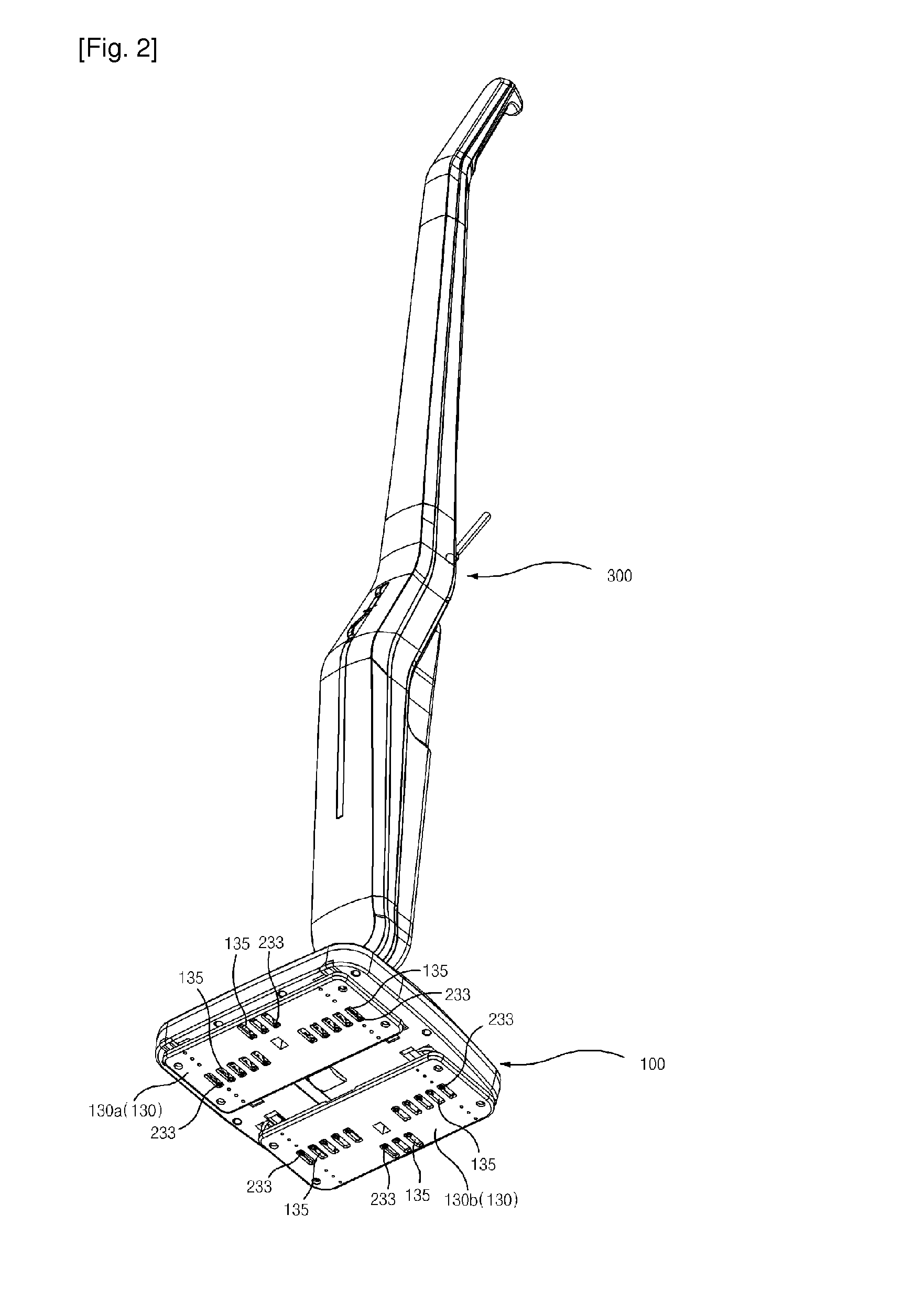

[0038]FIG. 1 is a front side perspective view illustrating a floor cleaner according to an exemplary embodiment of the present invention, FIG. 2 is a rear side perspective view of FIG. 1, and FIGS. 3 and 4 are front and rear side exploded perspective views illustrating a base assembly for the floor cleaner according to the exemplary embodiment of the present invention. In addition, FIGS. 5 and 6 are perspective views illustrating a principal part in assembled and disassembled states, respectively, FIG. 7 is a perspective view illustrating a driving member and a mounting case according to an exemplary embodiment of the present invention in a separated state, and FIG. 8 is a rear view of a base assembly for a floor cleaner according to an exemplary embodiment of the present invention. Moreover, FIG. 9 is a cross-sectional view taken along line q-q or line q-q o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com