Process and equipment for treating medical garbage

A technology of medical waste and treatment process, which is applied in the field of waste treatment, and can solve problems such as high moisture content, complex components, and excessive exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

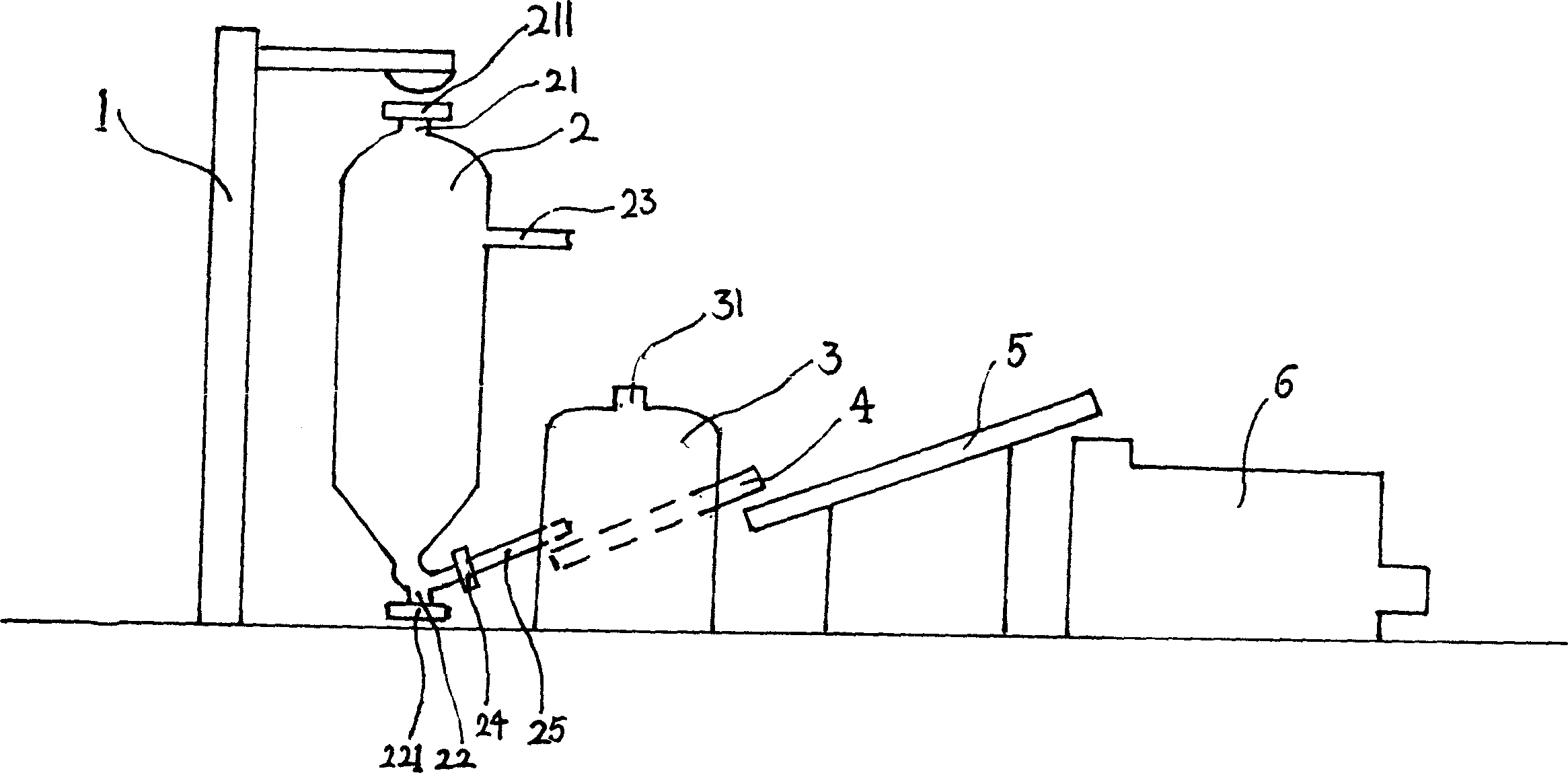

[0021] The principle and specific implementation of the medical waste treatment process and equipment provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0022] As shown in the figure, the composition of the medical waste treatment equipment provided by the present invention includes a waste conveying device 1, a comprehensive processor 2, a collector 3, a sorter 5, a wear-resistant pulverizer 6, and a point for transporting waste from the collector. Select the belt conveyor4. After the medical waste enters the comprehensive processor 2 through the feed port 21 at the upper end of the comprehensive processor 2 from the waste conveying device (elevator, conveyor belt) 1, the feed port 2 is sealed by the sealing mechanism 211, and then input 138 by the steam input device 23 ℃-160℃ steam, make the pressure in the comprehensive processor 2 reach 2-6 atmospheres, and keep it for 20-50 minutes, then open the garbage disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com