Dust removing device for motor production

A technology of dust removal device and driving device, which is applied in the direction of electromechanical devices, manufacturing motor generators, cleaning methods using gas flow, etc., can solve the problems of general dust removal effect, influence of rotor insulation, increase of air gap dust, etc., and achieve convenient maintenance And replace the effect, increase stability, expand the effect of purging range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

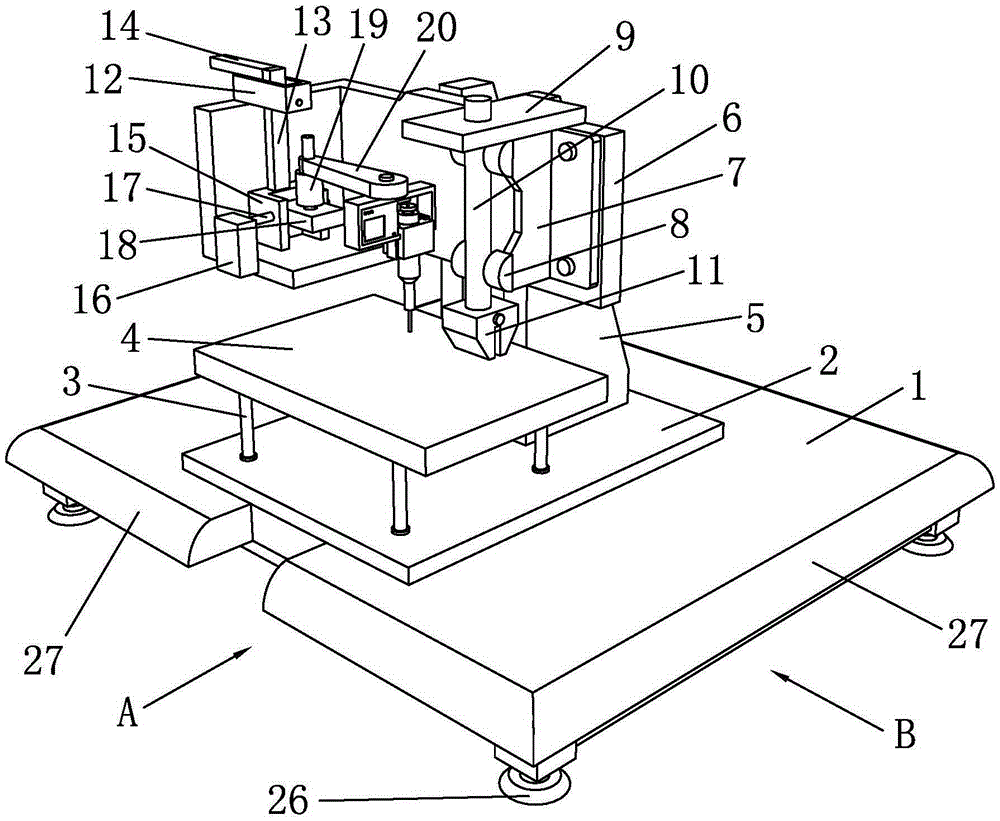

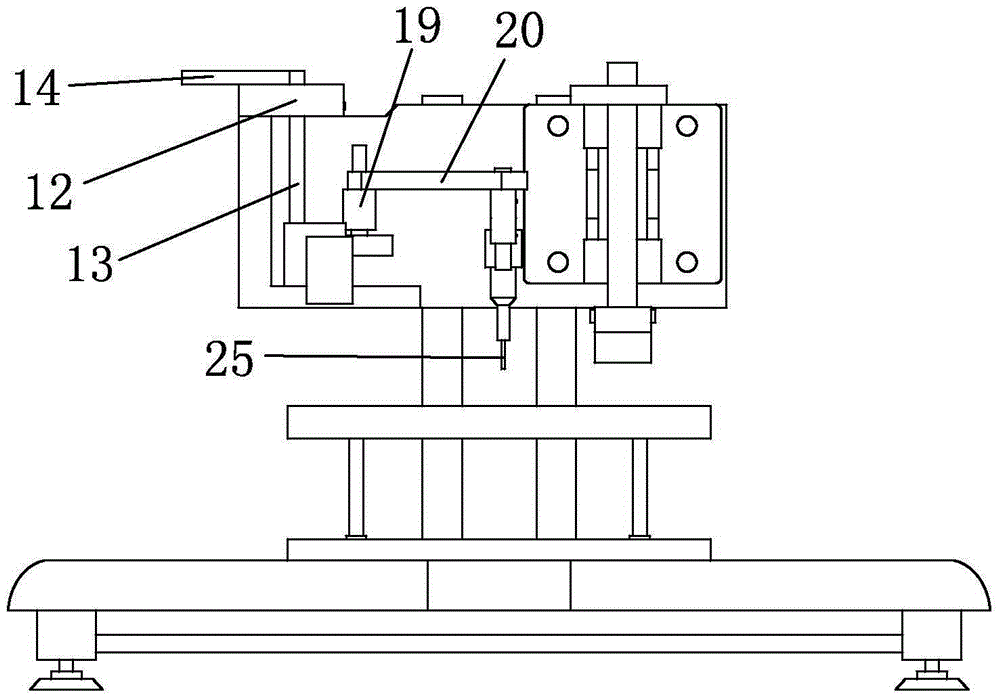

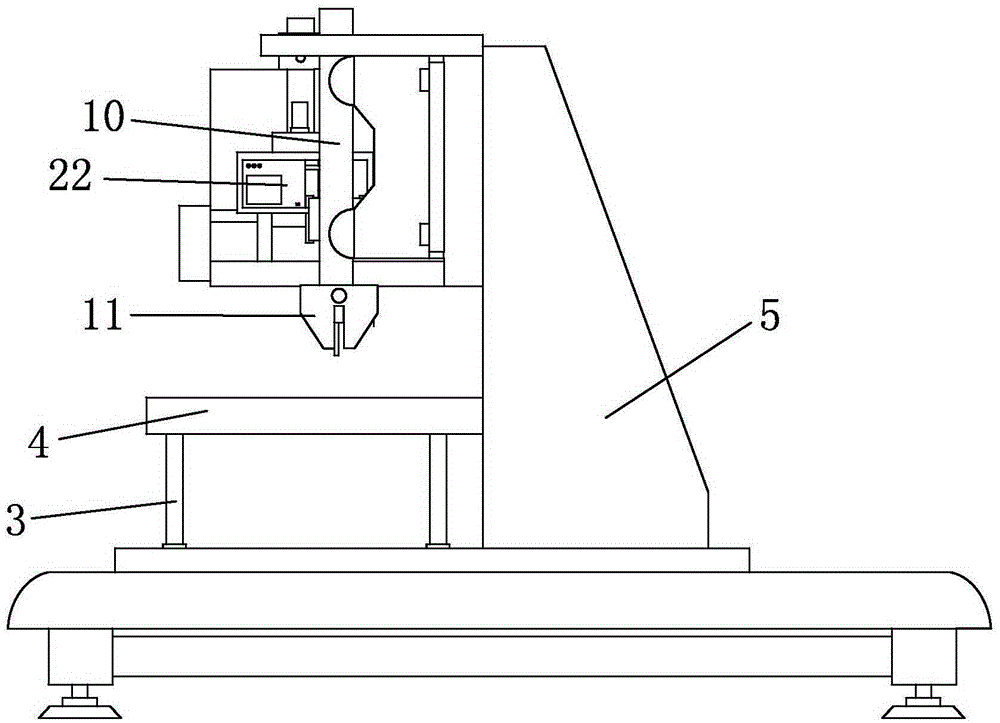

[0027] Such as Figure 1 to Figure 9 As shown, it is a dust removal device for motor production according to the present invention, which includes a base 1 , and a foot 26 is provided at the bottom of the base 1 . Support foot 26 comprises adjusting rod and plastic base, can adjust the overall height of supporting foot 26 by adjusting rod, can lift whole base 1 off the ground like this to a certain height, avoids the phenomenon that base 1 directly contacts with the ground and causes the bottom of base 1 to wear and tear, and The plastic base can increase the friction and improve the stability of the base 1 . Base 1 is provided with support plate 2, and support plate 2 is provided with support bar 3, and support bar 3 is to be connected on the support plate 2 by thread, is convenient to support bar 3 from support plate 2, is installed, disassembled, on support plate A washer is arranged between 2 and the support rod 3, which can increase the firmness of the support rod 3 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com