Circulating fluidized bed boiler uses high temperature cyclone separator to blow off the tail heating surface device

A technology of cyclone separator and circulating fluidized bed, which is applied in the direction of fluidized bed combustion equipment, lighting and heating equipment, fuel burning in melting state, etc., can solve the problem of reducing the economic benefits of circulating fluidized bed boilers, weakening flue gas and industrial Problems such as mass heat exchange and reduction of boiler thermal efficiency are achieved to achieve the effects of easy implementation, small structure size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

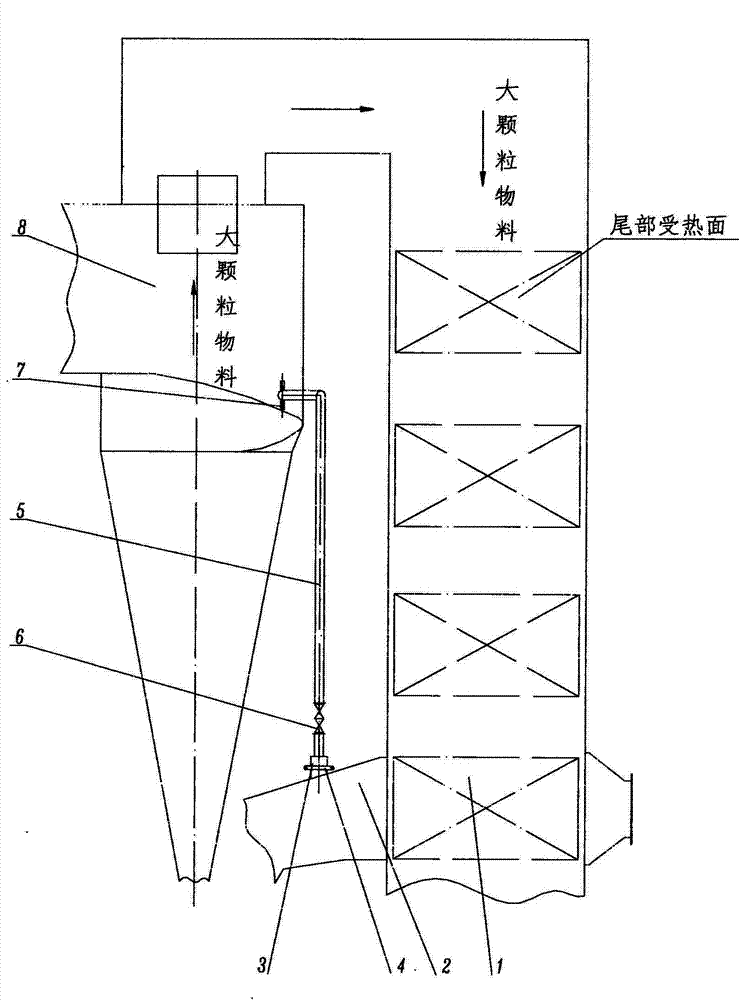

[0011] The circulating fluidized bed boiler of the present invention uses the high-temperature cyclone separator to blow off the tail heating surface device.

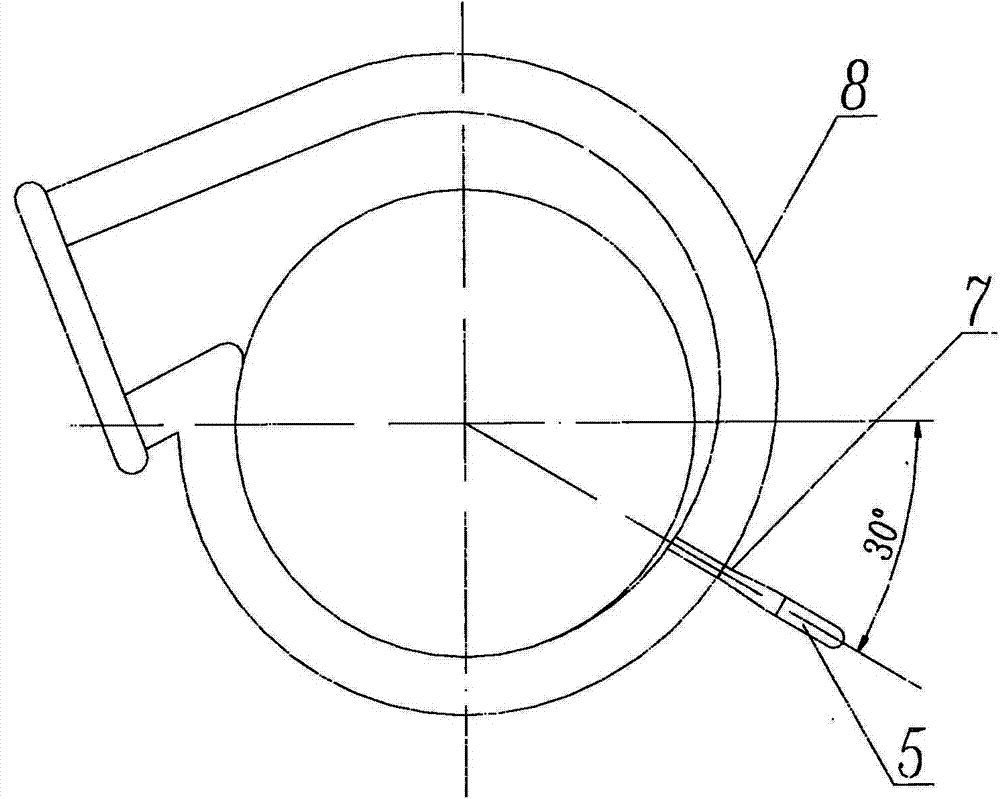

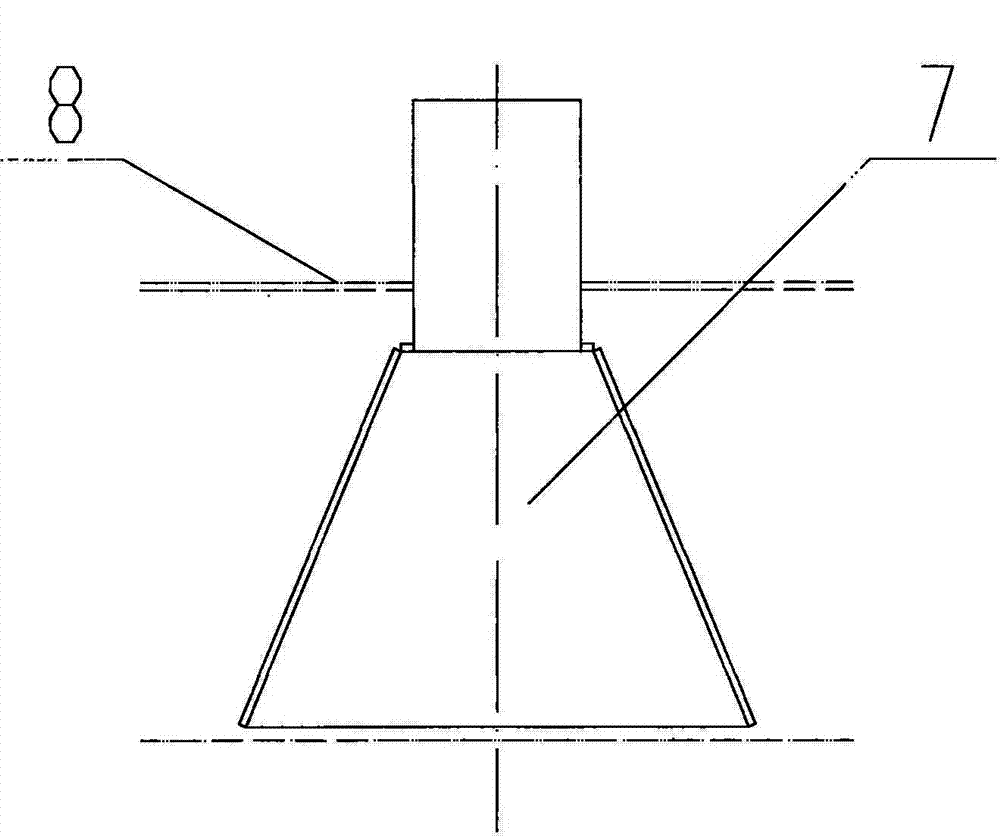

[0012] See Figure 1 ~ Figure 3 , the circulating fluidized bed boiler uses a high-temperature cyclone separator to purge the tail heating surface device, which is composed of: air preheater 1, primary air outlet duct 2, bellows 3, expansion joint 4, air pipe 5, butterfly valve 6, square mouth The nozzle 7 and the high-temperature cyclone separator 8 are composed. An air pipe 5 is arranged between the high-temperature cyclone separator 8 and the air preheater 1. The outlet of the air preheater 1 is provided with a primary air outlet duct 2. The air duct 2 is provided with a bellows 3, the air duct 5 communicates with the bellows 3 through the expansion joint 4, and the air duct 5 is provided with a butterfly valve 6 for opening and closing the blowing tail heating surface device. The high-temperature cyclone separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com