A centering guide device for steel strip processing

A guide and steel belt technology, applied in metal processing equipment, manufacturing tools, workpiece surface treatment equipment, etc., can solve problems such as flanging and warping of steel belts, avoid jamming, reduce labor intensity, and avoid left-right deviation. shift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

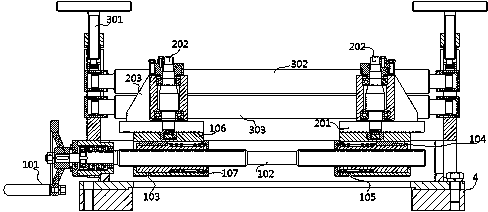

[0025] Such as figure 1 As shown, a centering and guiding device for steel strip processing in this embodiment includes a base 4, an adjustment mechanism, a guiding mechanism and a centering mechanism, wherein brackets are arranged symmetrically on both sides above the base 4, and the guiding mechanism It includes an upper horizontal roller 302 and a lower horizontal roller 303 arranged in parallel up and down, and the two ends of the upper horizontal roller 302 and the lower horizontal roller 303 are respectively fixed on the supports on both sides of the base 4; the two ends of the upper horizontal roller 302 are respectively provided with screw rods 301, the screw mandrel 301 is provided with a hand wheel, turning the hand wheel can realize the lifting and pressing down of the upper horizontal roller 302, thereby adapting to the range of motion in the upper and lower spaces of the steel strips of different thicknesses, the steel strip is lifted from the upper horizontal roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com