An Extrusion Process for Producing Asymmetric Special-shaped Seamless Pipes Using Round Pipes

An asymmetrical and seamless tube technology, applied in the field of extrusion technology, can solve problems such as product inner cavity twisting, thimble rotation, affecting normal production, etc., to achieve the effect of improving balance and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

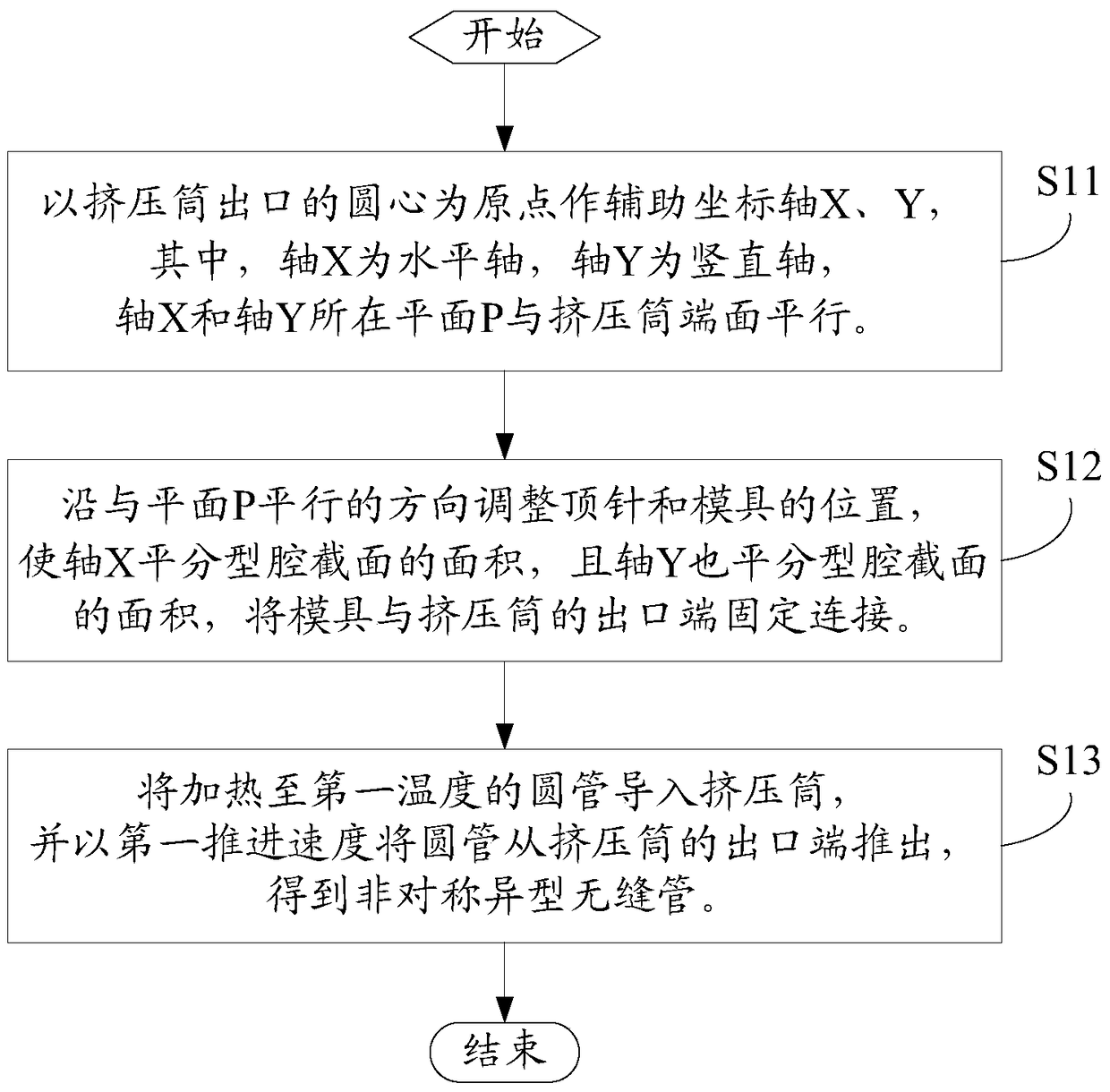

[0019] see figure 1 , a flow chart of an extrusion process for producing an asymmetric special-shaped seamless pipe using a round pipe provided by the present invention, specifically including:

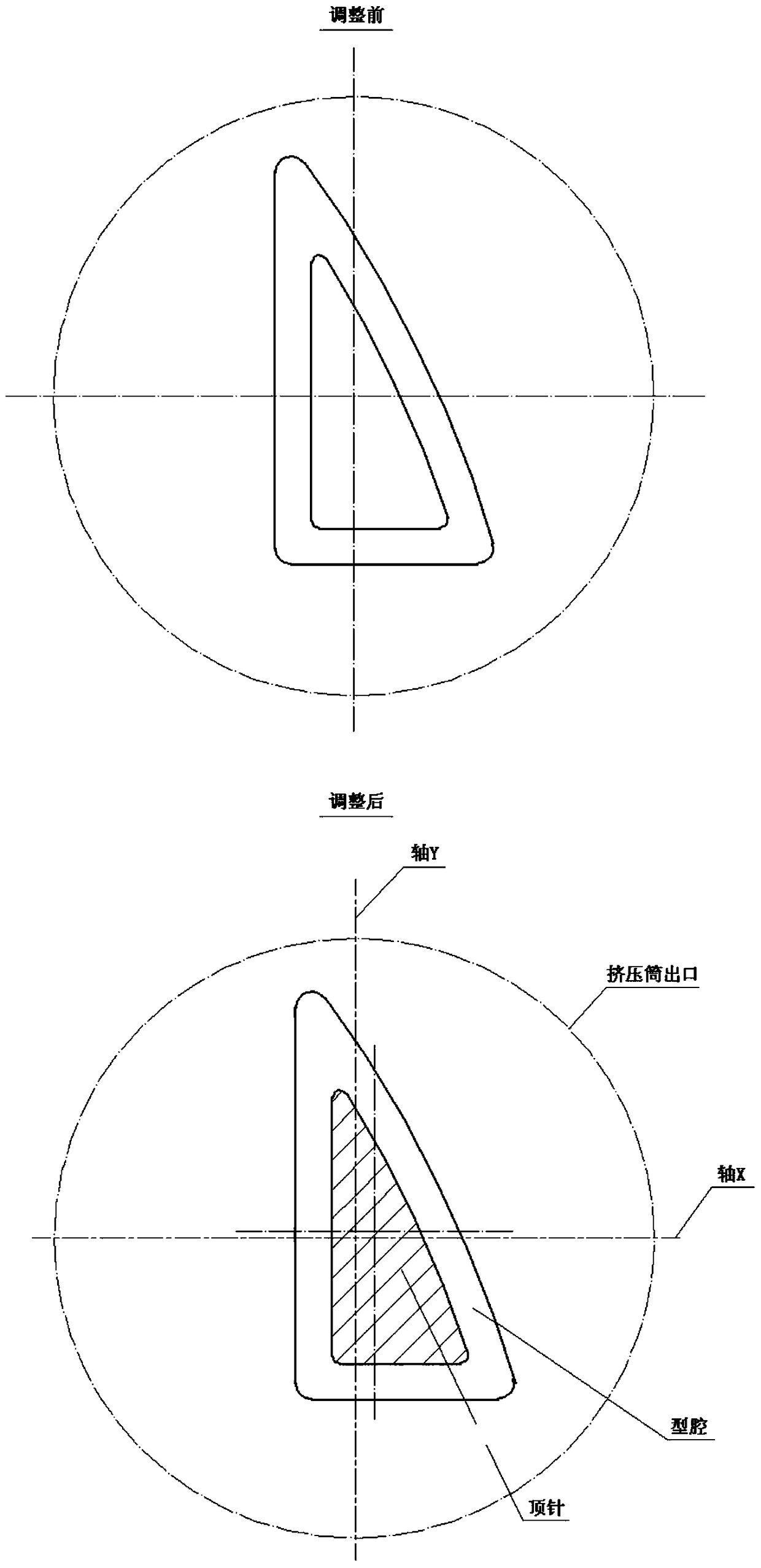

[0020] Step S11, take the center of the exit of the extrusion cylinder as the origin as the auxiliary coordinate axes X and Y, wherein the axis X is the horizontal axis, the axis Y is the vertical axis, and the plane P where the axes X and Y are located is parallel to the end surface of the extrusion cylinder.

[0021] It should be noted that the auxiliary coordinate axes X and Y are virtual straight lines, which only serve to divide the section of the cavity and will not affect the extrusion of the raw material tube from the exit of the extrusion cylinder.

[0022] Step S12, adjust the position of the thimble and the mold along the direction parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com