Bolt-tensioning-pretightened device and assembly formed by bolt-tensioning-pretightened device

A technology for bolts and components, which is applied in the field of bolt tensioning pretensioning devices and components composed of the devices, which can solve problems such as damage to bolts, nuts or sealing rings, unbalanced force on the connecting plate surface, and different pretensioning forces. Achieve the effects of preventing thread wear, high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

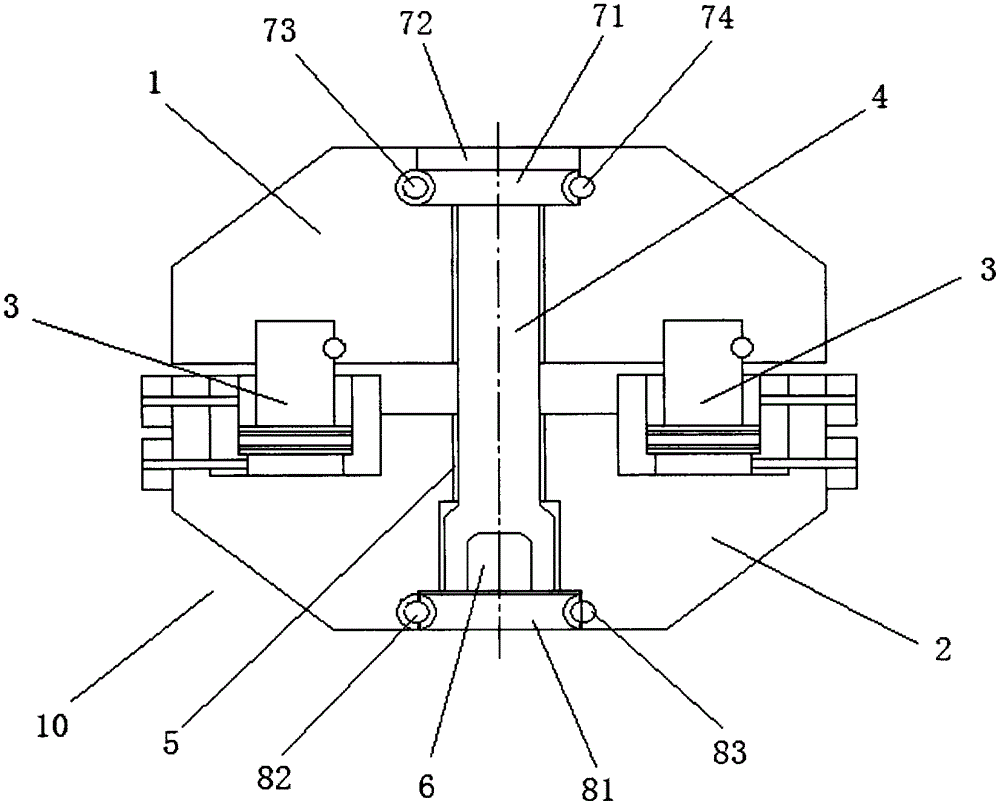

[0025] see figure 1 , a bolt tensioning pretensioning device, which includes a support 1 and a top plate 2, an oil cylinder 3 is arranged between the support 1 and the top plate 2, and the bottom of the oil cylinder 3 is fixed on the support 1, so The end of the ejection end of the oil cylinder 3 is fixed on the top plate 2, and the oil cylinder 3 drives the top plate 2 away from or close to the support 1; The pull rod 4 on the surface, the top plate 2 is provided with a through hole 5 for the pull rod 4 to pass through, the end of the pull rod 4 away from the support 1 is provided with a groove 6, and the groove 6 is connected to the The pull rod 4 is coaxial, the inner cavity of the groove 6 is a cylindrical structure, and its side wall is provided with an internal thread that matches the external thread of the bolt to be stretched; the support 1 is provided with a 4 forward or reverse rotation to screw the groove 6 into or out of the first driving device of the bolt to be ...

Embodiment 2

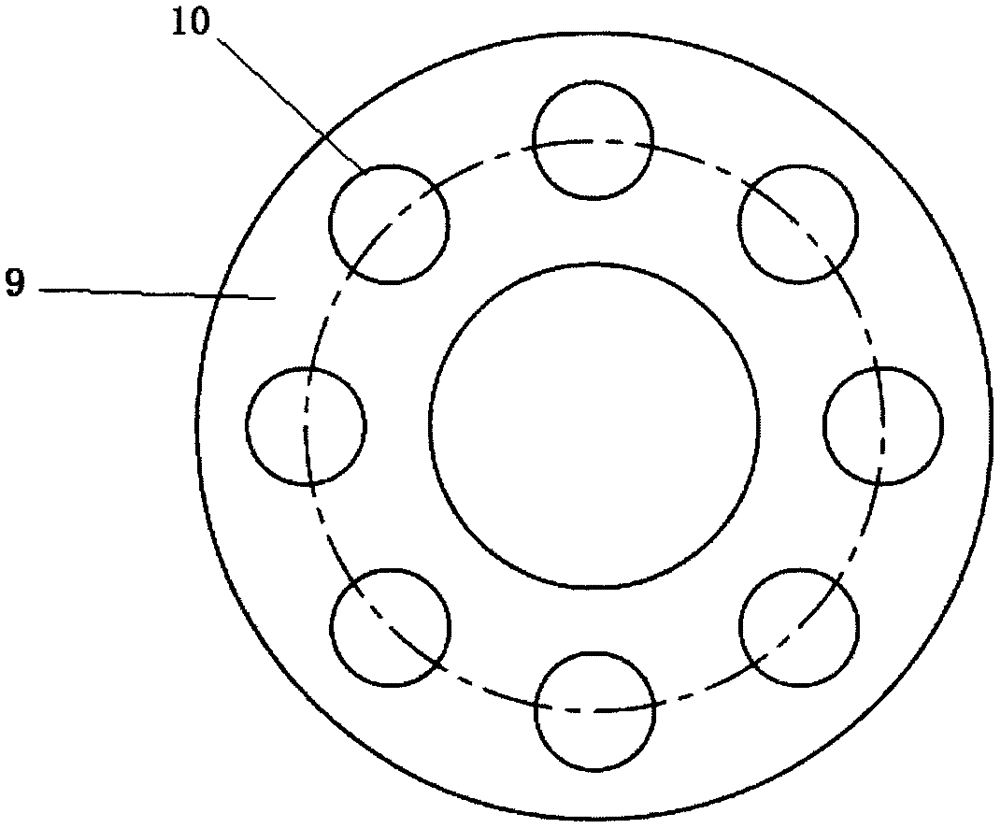

[0033] see figure 2 , a bolt tensioning pretensioning assembly, which includes a chassis 9, a plurality of bolt tensioning pretensioning devices 10 are arranged on one end surface of the chassis 9, and several bolt tensioning pretensioning devices 10 are arranged along the circumferential direction Arranged at even intervals, the bolt tensioning pretensioning device 10 is the bolt tensioning pretensioning device described in the first embodiment above, and several oil cylinders, the first driving and rotating device, and the second bolt tensioning pretensioning device 10 are arranged. The two driving and rotating devices are controlled synchronously, so that each bolt on the circumference of the flange-type connection object can be stretched by the same amount at the same time. After the nut is pre-tightened, the bolt is released, and the bolt shrinks axially under the action of the restoring force. The contraction strength of each bolt is equal, thereby ensuring that the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com