Manual operating tool for inserted connection of slotted head steel tubes

A manual operation, steel pipe technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of not being able to use ordinary tools, reduce labor intensity, prevent oil theft and oil theft process accidents, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the embodiments of the present invention are only used to illustrate the present invention and not to limit the present invention. Without departing from the technical idea of the present invention, various replacements and changes can be made according to common technical knowledge and conventional means in the field. All should be included within the scope of the present invention.

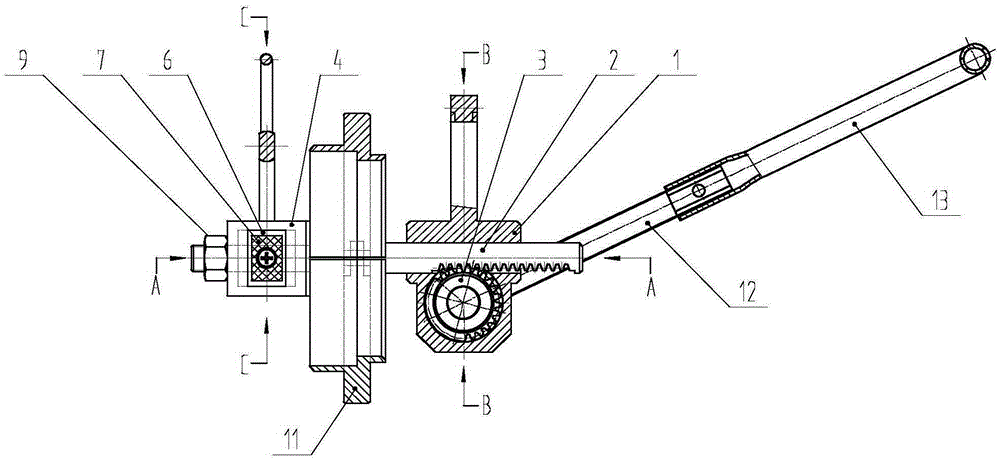

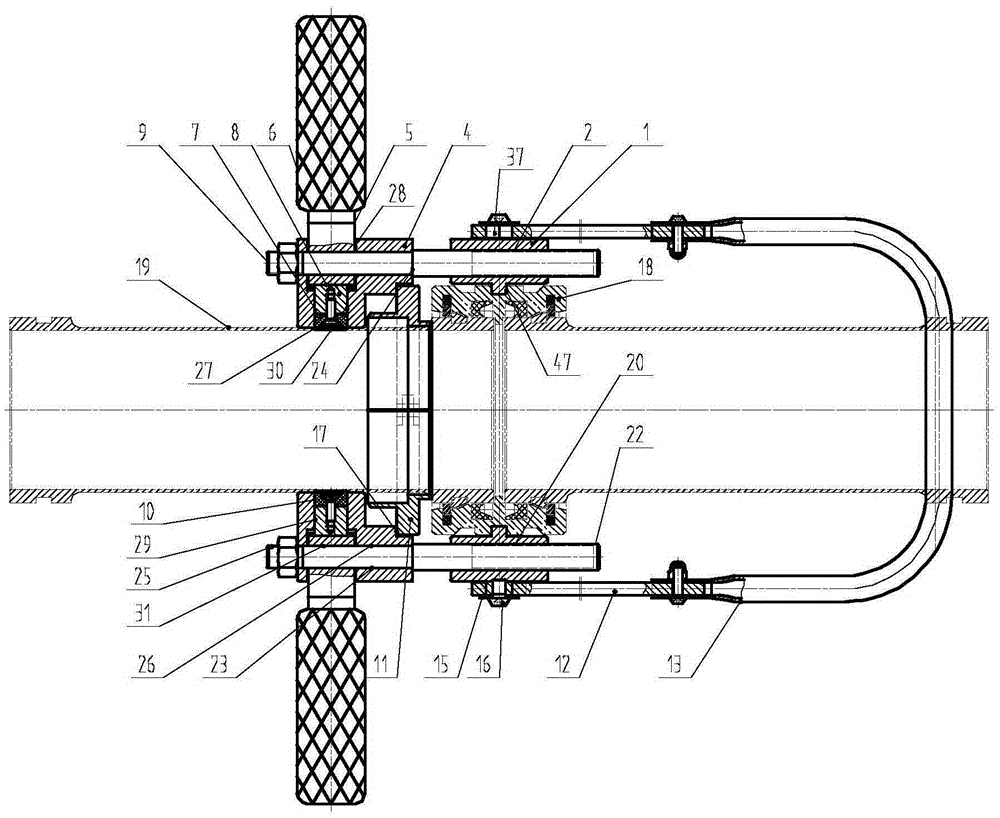

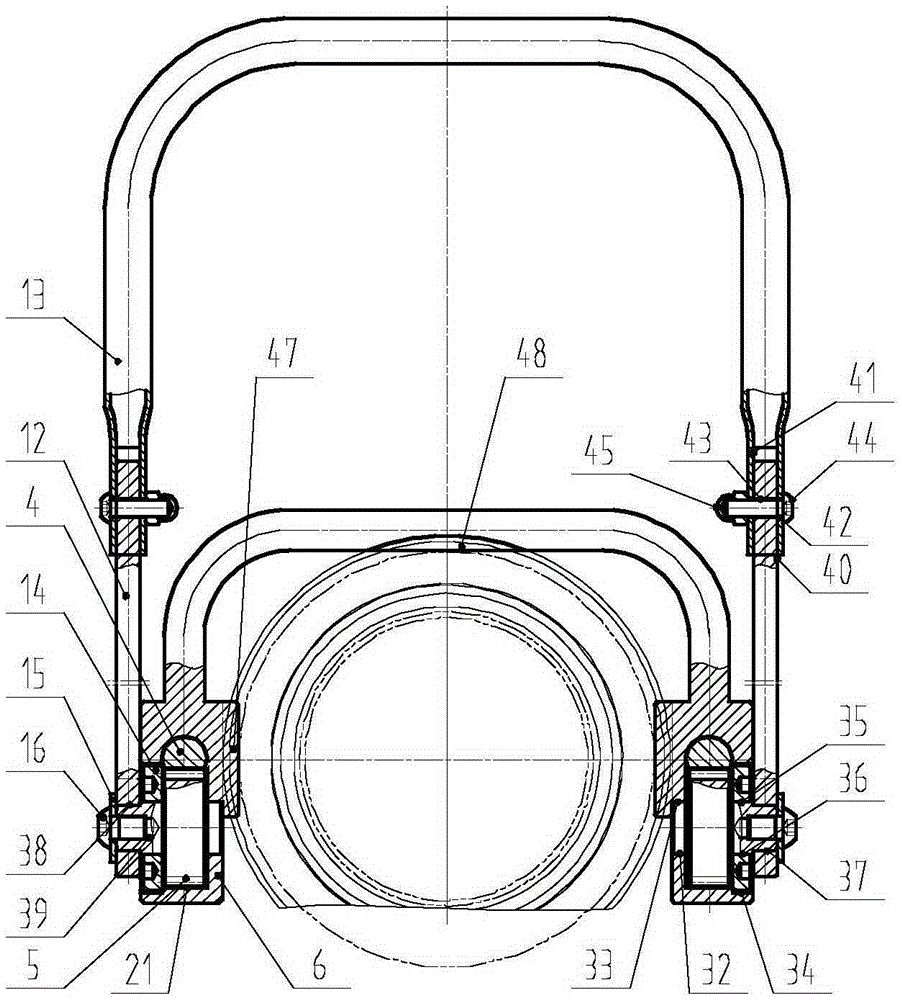

[0029] Such as figure 1 and figure 2As shown, a special tool for plug-in connectors, including box body 1, rack shaft 2, gear 3, chuck body 4, pedal 5, chuck 6, friction plate 7, assembly and disassembly sleeve assembly 11. Handle head 12, handle 13, box cover 14; axial hole I20 and transverse hole I21 are respectively set in the box body 1, and boss 47 is set near the side of the pipeline in the box body 1; the rack shaft 2 Slidingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com