Service Brake Protection Valves and Work Vehicles

A brake protection valve and service braking technology, which is applied in the field of vehicles, can solve the problems such as the difficulty of ensuring the consistency of the rollover model and the calculation results, the difficulty in detecting key parameters, and the difficulty in implementation, so as to achieve easy structure and control process, and avoid rollover. Accident, pressure output softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

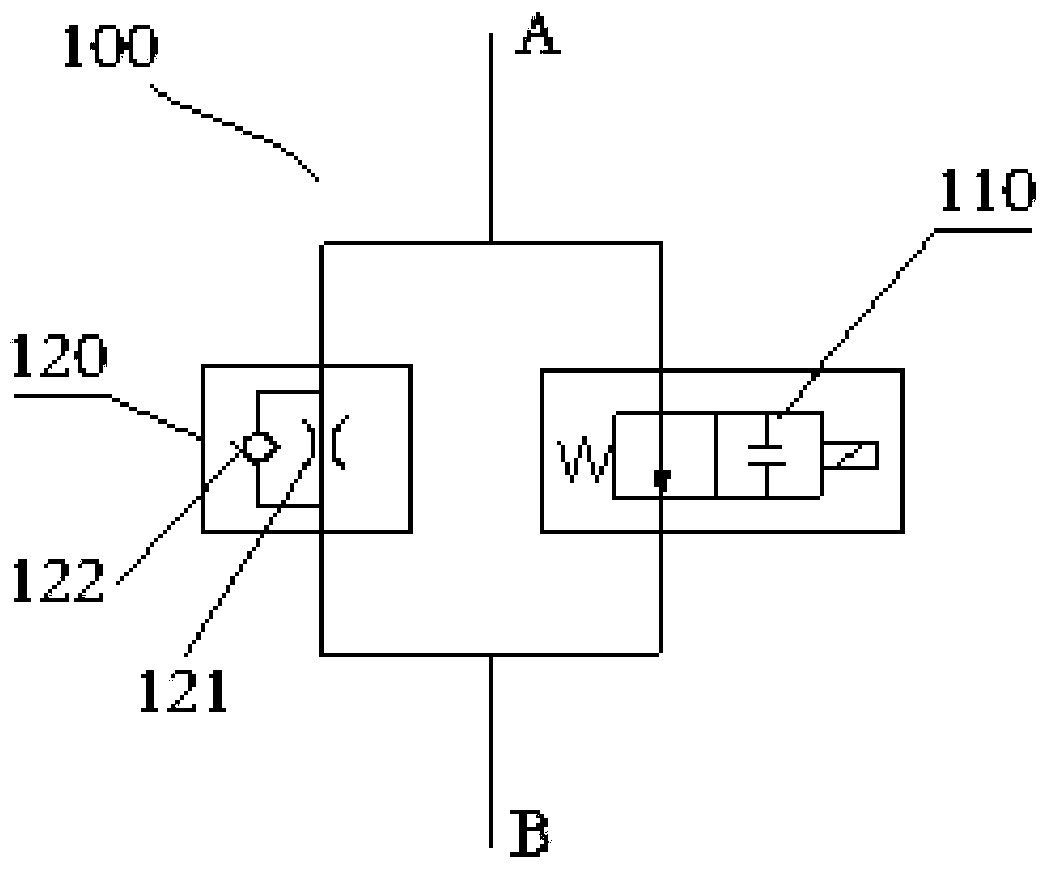

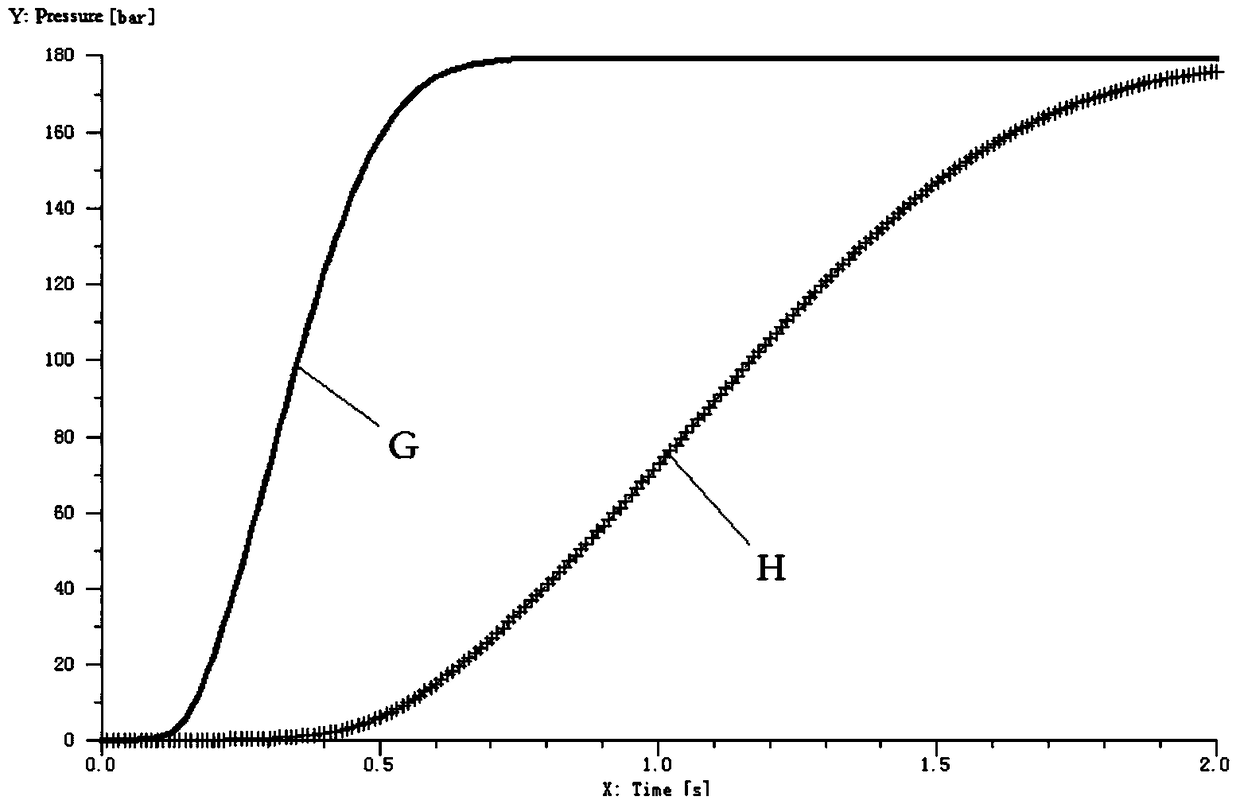

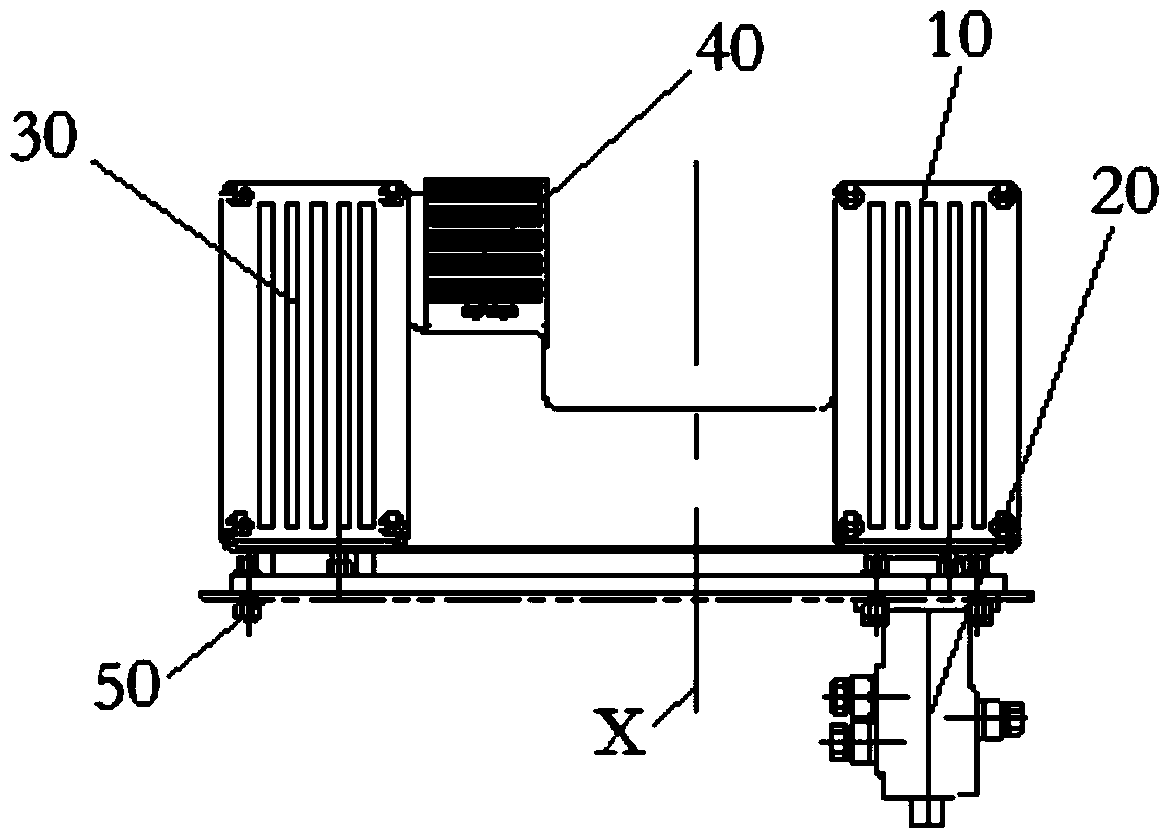

[0043] figure 1 It is a schematic diagram of the principle of the service brake protection valve of the first embodiment of the present invention.

[0044] Such as figure 1 As shown, the service brake protection valve 100 of the first embodiment has a first connection port A, a second connection port B and includes a switching module and a pressure limiting module. Wherein the first connection port A is used to connect with the service brake valve of the service brake system of the working vehicle, and the second connection port B is used to connect with the brake cylinder of the service brake system. Wherein, the switching module can control the service brake protection valve to switch between the first working mode and the second working mode. In the first working mode, the first connection port A communicates with the second connection port B through the switching module. In the second working mode, the first connection port A communicates with the second connection port...

no. 2 example

[0070] Figure 4 It is a schematic diagram of the principle of the service brake protection valve of the second embodiment of the present invention.

[0071] The difference between the service brake control valve of the second embodiment and the first embodiment is that in the second embodiment, the pressure limiting element of the pressure limiting sub-module is not a throttling device, but a pressure reducing device.

[0072] Such as Figure 4 As shown, the service brake control valve 200 of the second embodiment has a first connection port C and a second connection port D, the first connection port C is used to connect with the service brake valve, and the second connection port D is used to connect with the brake valve. Cylinder connection. The service brake valve protection valve 200 includes a switching module and a pressure limiting module. The switching module and the pressure limiting module are arranged in parallel. The switching module includes a reversing valve...

no. 3 example

[0079] Figure 5 It is a schematic diagram of the principle of the service brake protection valve of the third embodiment of the present invention.

[0080] Such as Figure 5 As shown, the service brake protection valve 300 of the third embodiment has a first connection port E, a second connection port F and includes a switching module M1 and a pressure limiting module M2. Wherein the first connection port E is used to connect with the service brake valve of the service brake system of the working vehicle, and the second connection port F is used to connect with the brake cylinder of the service brake system. Wherein, the switching module M1 can control the service brake protection valve 300 to switch between the first working mode and the second working mode. In the first working mode, the first connecting port E communicates with the second connecting port F through the switching module M1, and in the second working mode, the first connecting port E communicates with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com