Marked fixed-length cut wire packaging box

A wire, fixed-length technology, applied in the field of printing, marking, length-cutting, and wire packaging boxes, can solve the problems of wire damage, transparent wrapping paper being easily damaged, affecting the normal use of wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

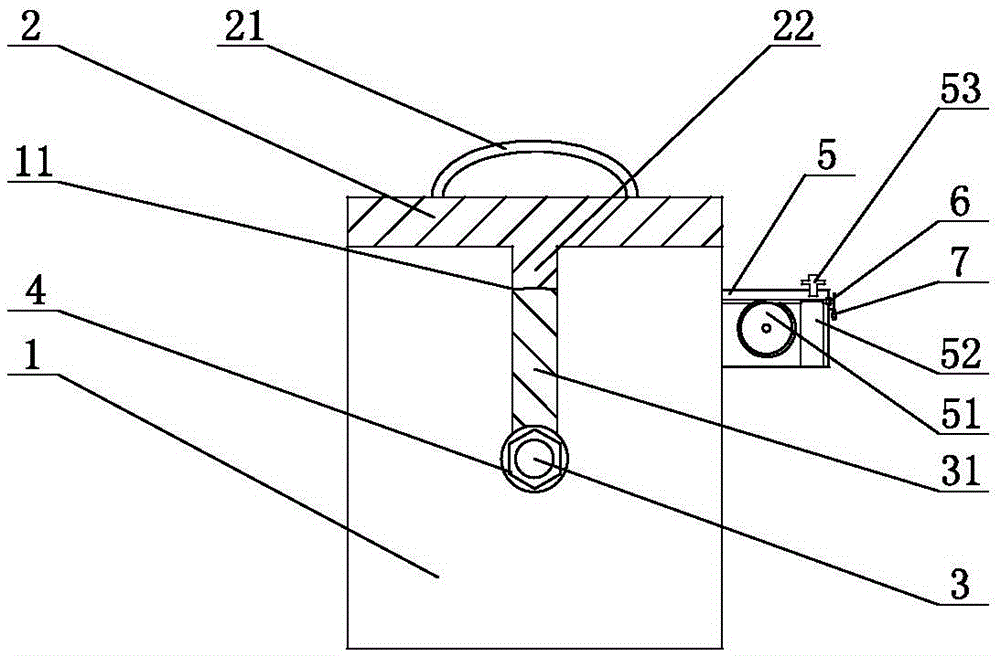

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

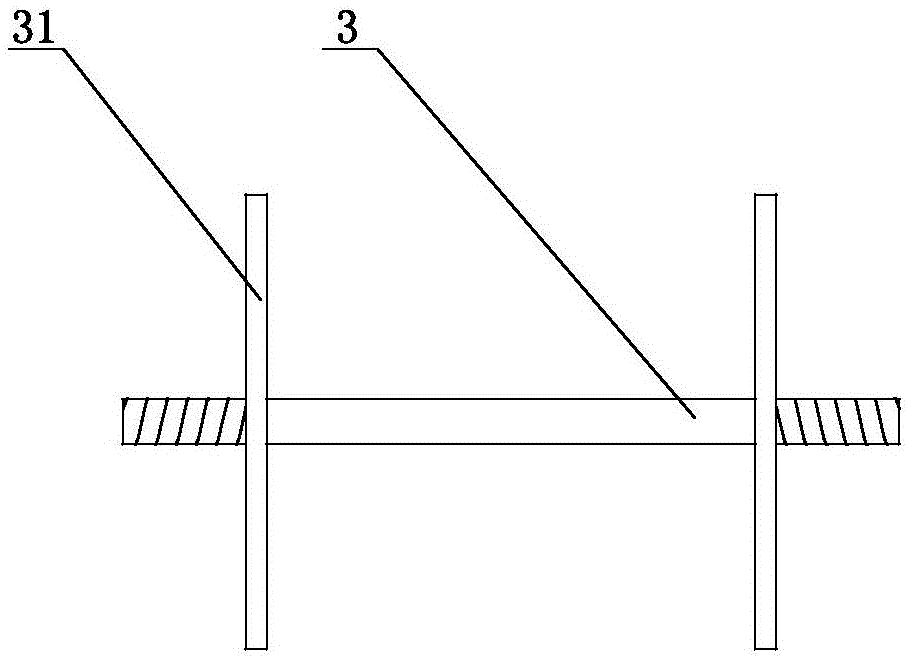

[0011] like figure 1 , 2 As shown, the printed and marked long-cut wire packaging box of the present embodiment includes a box body 1, an upper cover 2, a wire roller 3 and a roller nut 4, and roller mounting holes 11 are provided on the front and rear side walls of the box body 1. Front and rear baffles 31 are set on the wire roller 3, and the electric wires are wound between the front and rear baffles 31 of the wire roller 3. 3. The part with external thread is erected in the roller installation hole 11, and the roller nut 4 is sleeved on the position of the electric wire roller 3 outside the roller installation hole 11, and is close to the side walls of the front and rear sides of the box body 1. The cover 2 is clamped on the top of the box body 1, and a handle 21 is provided, and the upper cover 2 is provided with a protrusion 22 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com