Paint barrel

A paint barrel and barrel body technology, applied in the field of paint barrels, can solve the problems of paint barrels colliding with each other, waste, paint outflow, etc., and achieve the effect of avoiding mutual collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the technical means, creative features, goals and effects achieved by this application easy to understand, the following will further elaborate this application in conjunction with specific implementation methods.

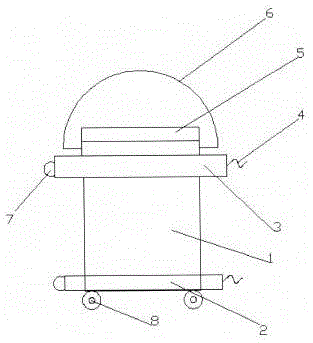

[0009] refer to figure 1 , the specific embodiment adopts the following technical solutions: a paint bucket, including a bucket body 1 and a bucket cover 5, a handle 6 is installed on the top of the bucket body 1, and the upper and lower outer sides of the bucket body 1 are covered with protective Ring I4 and protective ring II2, the diameters of the protective ring I4 and the protective ring II2 are connected, the side of the protective ring I4 and the protective ring II2 is provided with a hook 4, the protective ring I4 and the protective ring The other side of II2 is provided with a ring 7 .

[0010] It should be noted that the bottom of the barrel body 1 is provided with wheels 8 with braking devices.

[0011] In this specific implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com