Lifting hook capable of achieving automatic engagement and disengagement

A hook and automatic technology, applied in the field of automatic hooking and decoupling hooks, hooks, can solve problems such as hidden safety hazards, low work efficiency, injury to staff, etc., and achieve collision prevention, convenient operation and strong automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

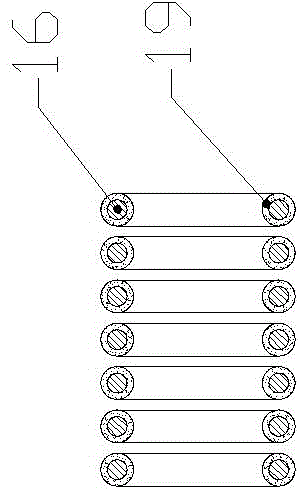

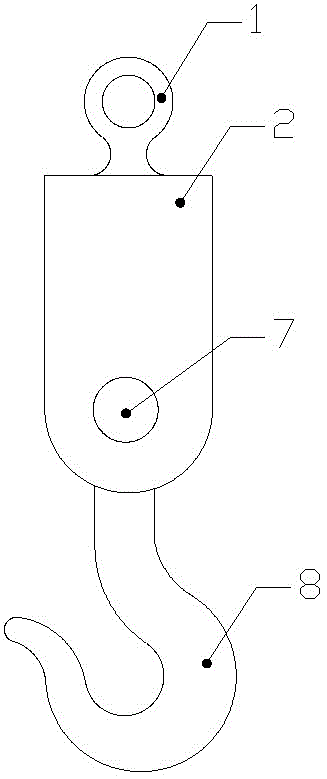

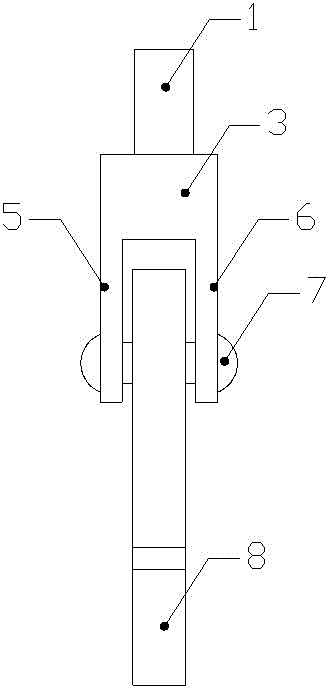

[0025] like Figure 1-6 As shown, a hook capable of automatic hooking and unhooking, it includes a suspension ring 1, the lower end of the suspension ring 1 is provided with a fixed plate 2, the fixed plate 2 is composed of a horizontal plate 3, a vertical plate 4, a side plate A5 and the side plate B6; the middle part of the side plate A5 and the side plate B6 passes through a hinge shaft 7, and the hinge shaft 7 is connected with a hook 8, and one side of the upper end of the hook 8 is opened. There is a hole A9, a cross bar A10 is arranged in the hole A9, a threaded hole 11 is arranged on the lower side of the hole A9, a threaded column 12 is arranged in the threaded hole 11, and the right end of the threaded column 12 is arranged There is a permanent magnet 13; a hole B14 is provided at the position opposite to the hole A9 on the vertical plate 4, and a cross bar B15 is arranged in the described hole B14, and a spring 16 is connected on the described cross bar B15. The ot...

Embodiment 2

[0028] like Figure 1-6 As shown, a hook capable of automatic hooking and unhooking, it includes a suspension ring 1, the lower end of the suspension ring 1 is provided with a fixed plate 2, the fixed plate 2 is composed of a horizontal plate 3, a vertical plate 4, a side plate A5 and the side plate B6; the middle part of the side plate A5 and the side plate B6 passes through a hinge shaft 7, and the hinge shaft 7 is connected with a hook 8, and one side of the upper end of the hook 8 is opened. There is a hole A9, a cross bar A10 is arranged in the hole A9, a threaded hole 11 is arranged on the lower side of the hole A9, a threaded column 12 is arranged in the threaded hole 11, and the right end of the threaded column 12 is arranged There is a permanent magnet 13; a hole B14 is provided at the position opposite to the hole A9 on the vertical plate 4, and a cross bar B15 is arranged in the described hole B14, and a spring 16 is connected on the described cross bar B15. The ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com