A method of constructing underground garage by utilizing the bad situation of slope land

A kind of underground garage, poor technology, applied in the direction of buildings, building types, building components, etc., can solve the problems that parking can only be located in the courtyard and the first floor of the building, increase the amount of filling, and increase the construction period, etc., to achieve effective It is beneficial to site road and landscape planning, saves construction costs and improves construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

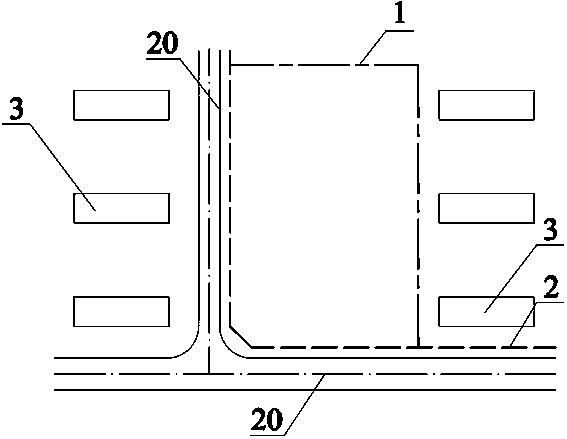

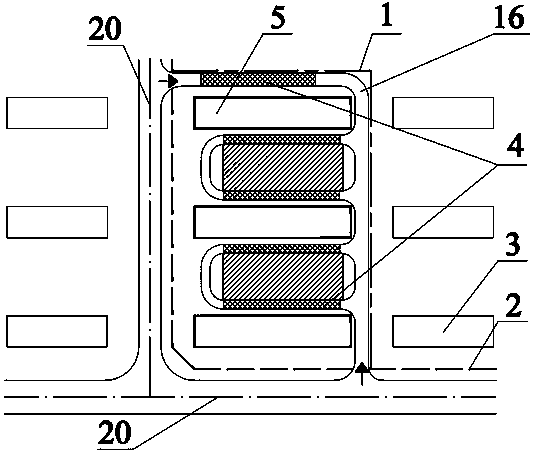

[0057] Such as Figure 7~11 Shown is a method for building an underground garage when the slope is 8%. It includes a planning area. The planning area is equipped with a garage area and a ramp area 4, and the garage area is equipped with an underground garage area 11 and a street shop area 6, and a street shop area At the lowest elevation of the original natural floor of the site 6, an entrance area 12 to enter the underground garage area and a step area 13 for people to enter and exit the ground are set.

[0058] The specific planning and construction steps include: (1) First plan the location of the planning area, plan out the underground garage area 11 according to the location of the planning area, reserve a later ramp area 4 next to the underground garage area 11, and follow the underground garage area 11 during construction. The outer wall can be paved with multiple straight-line two-way fire lanes and pedestrian and non-motor vehicle roads 16 in the site. When there is a fir...

Embodiment 2

[0064] The design method of embodiment 2 is roughly the same as that of embodiment 1, and the building structure is also roughly the same. The difference is: Figure 12~14 As shown, the underground garage area 11 can be set as a basement level or two underground levels. The height of the garage and the lowest ground elevation of the basement level can be calculated according to the calculation in Example 1. In the basement level garage area 15 Design the ramp into the underground second-story garage area 18, the slope of the ramp is 15%, and the ramp entrance between the garages is separated by a fire-proof rolling shutter with a fire resistance rating of not less than 3 hours.

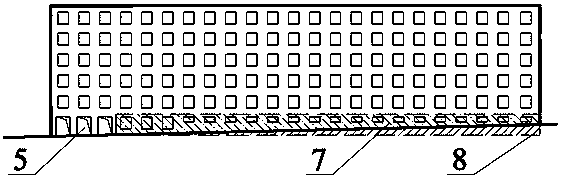

[0065] Due to waterproof and moisture-proof requirements, the ground of the proposed building 5 in the upper part of the underground garage area 11 needs to be higher than the roof of the garage, so that the height between the lower part of the main building and the underground garage area 11 is higher th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com