Rapid connecting structure of LED lamp wick

A technology of LED wick and quick connection, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve problems such as unsuitable connection structures, and achieve the effect of simple structure and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

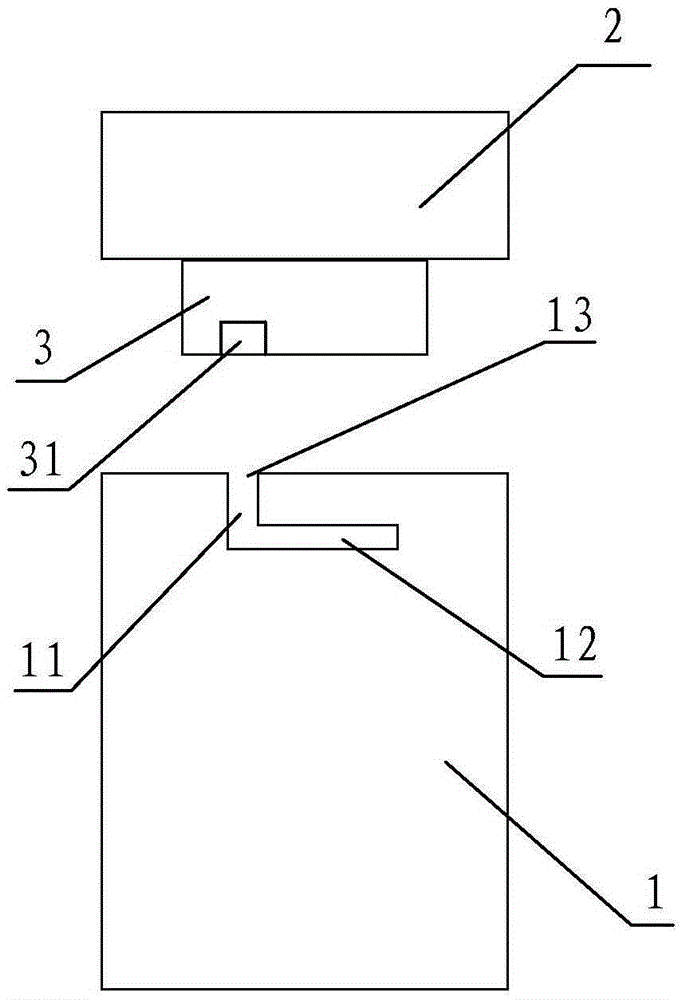

[0013] Such as Figure 1-2 As shown, a quick connection structure of an LED wick includes a connecting end of the LED wick 1 and a lamp holder 2 connected to the LED wick 1. The end of the lamp holder 2 connected to the LED wick 1 is provided with a tubular protrusion 3, and the tubular protrusion 3 is provided with a protrusion 31 on the outer wall, and one end of the LED wick 1 connected to the lamp holder 2 is provided with a first chute 11 and a second chute 12 capable of accommodating the sliding of the protrusion 31 , the first chute 11 and the second chute The angle between 12 is 30-90 degrees, and the first chute 11 is provided with an opening 13 at the end where the LED wick 1 is connected to the lamp holder 2 to accommodate the protrusion 31 to slide in.

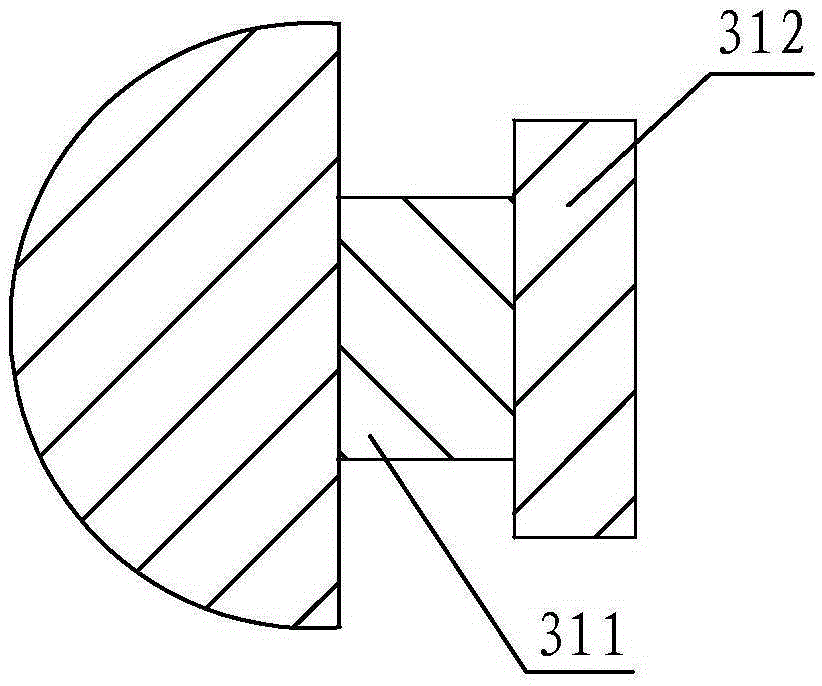

[0014] The bump 31 includes a connecting block 311 and a slider 312 arranged on the outer wall along the radial direction of the tubular boss 3, and the size of the slider 312 along the axial direction of the tubul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com