Blast hole depth gauge and measuring device

A measuring instrument and hole depth technology, which is used in measuring devices, mechanical depth measurement, radio wave measurement systems, etc., can solve the problems of difficulty in accurately measuring the actual hole depth, insufficient precision and accuracy, and large discrepancies in the explosion area. Achieve the effect of single-person on-site measurement operation, reduce work intensity, and improve fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] The purpose of this specific embodiment is to accurately measure the hole depth under the condition that there is water in the blast hole.

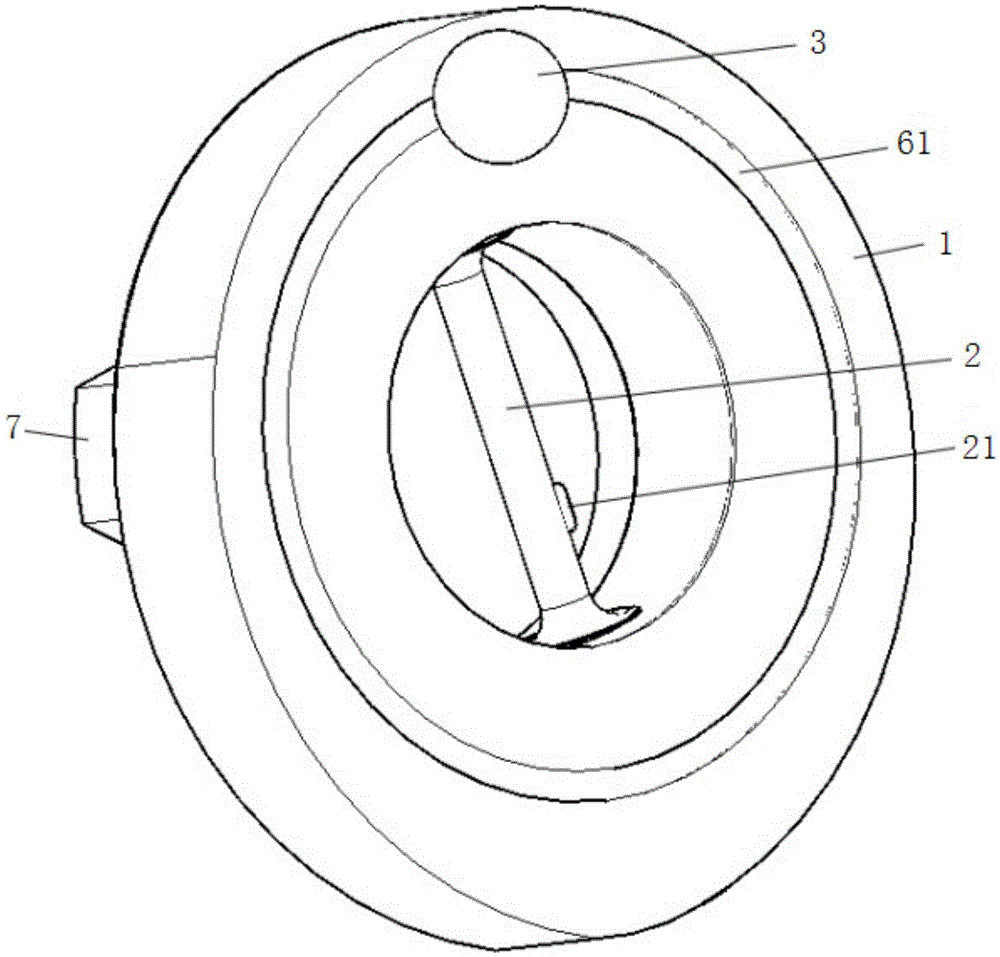

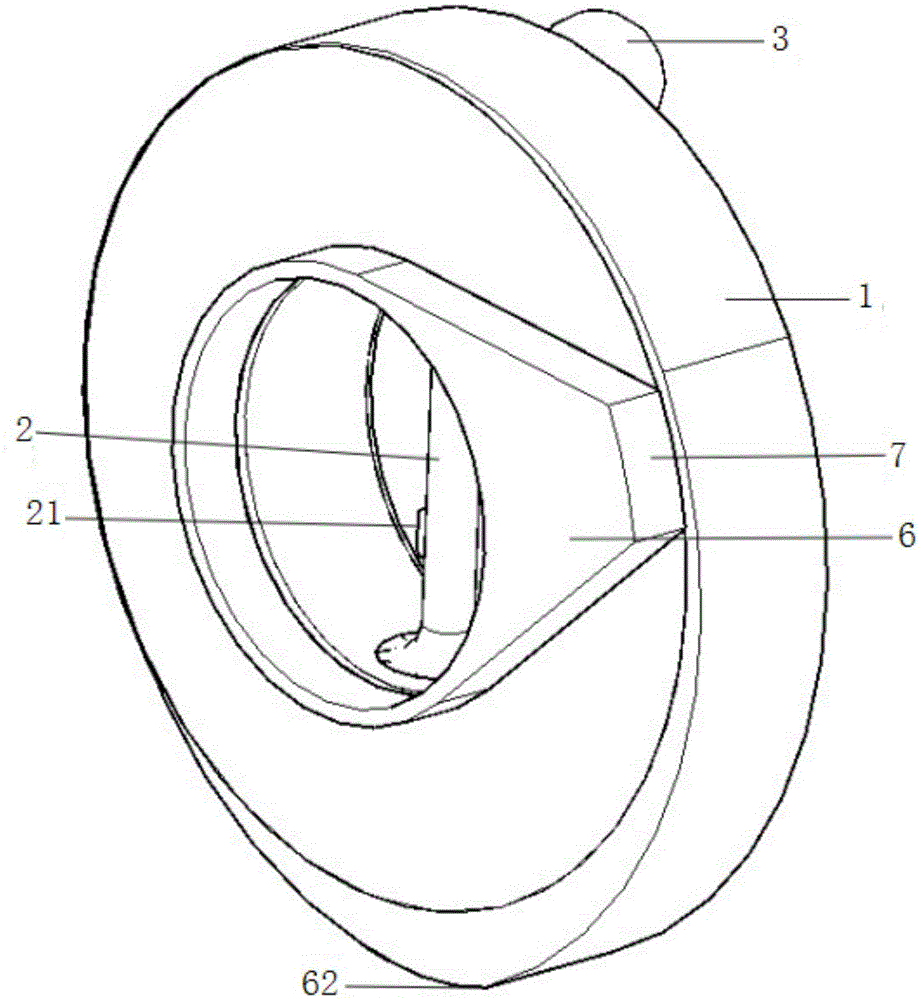

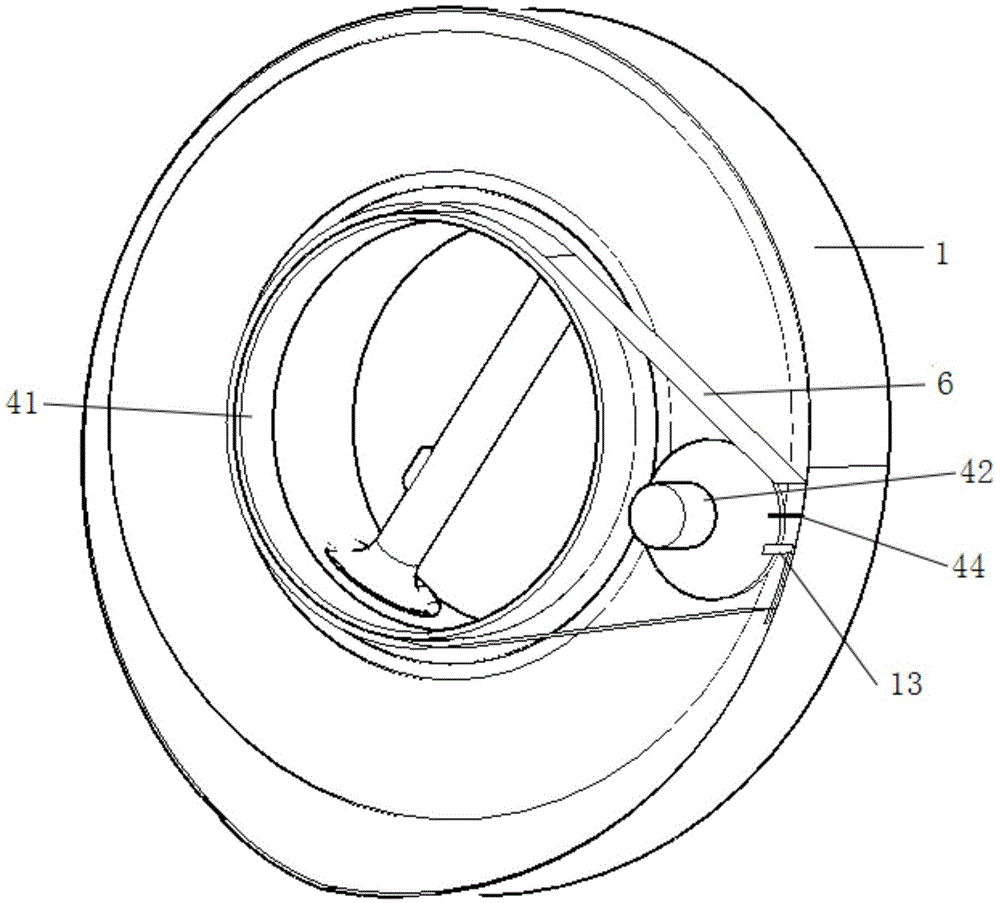

[0027] Such as figure 1 , figure 2 As shown, a blasthole depth measuring instrument includes a casing 1, a handle 2, a crank 3, a winding wheel 4, a measuring rope, a weight 5, and a depth display device 6, and the handle 2 is arranged on the casing 1 The middle part, the crank handle 3, the winding wheel 4, and the depth display device 5 are all fixed on the shell 1, such as image 3 As shown, the depth display device 6 includes an observation window 7, such as Figure 4 As shown, the blasthole depth measuring instrument also includes a measuring rope pressure sensing device, and the measuring rope pressure sensing device includes a measuring rope winding fixed roller 8, a measuring rope winding action roller 9, a measuring rope pressure sensing plate 10, a spring leaf 11, a spring The fixed plate 12, the spring leaf pointer ...

specific Embodiment approach 2

[0035] Since the measurement of the blasthole depth usually requires synchronous GPS positioning operations, this embodiment is mainly to facilitate the carrying of measuring instruments, GPS receivers and other equipment.

[0036] Such as Figure 10 As shown, a blasthole depth measuring device includes the blasthole depth measuring instrument in Embodiment 1, the hole depth measuring device also includes a carrying device, and the carrying device includes a measuring instrument frame 71, a belly top device 72, and a strap 73 , the measuring instrument frame 71 includes a measuring instrument carrying groove 74, the belly top device 72 includes a belly top belt 75 and a belly ejector bar 76, one end of the belly ejector bar 76 is connected to the measuring instrument frame 71 through a Y-shaped joint 77, and the other end of the belly ejector bar 76 passes through The universal joint 78 is connected to the belly top belt 75, and the strap 73 is connected to the measuring instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com