High-speed EMU axle end grounding device wear test bench

A technology for high-speed EMUs and grounding devices, applied in the direction of testing wear resistance, etc., can solve the problem that the test bench cannot simulate high-speed working conditions, and achieve the effect of improving the overall technical level, ensuring test data, and avoiding rapid wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing, the present invention is described in further detail:

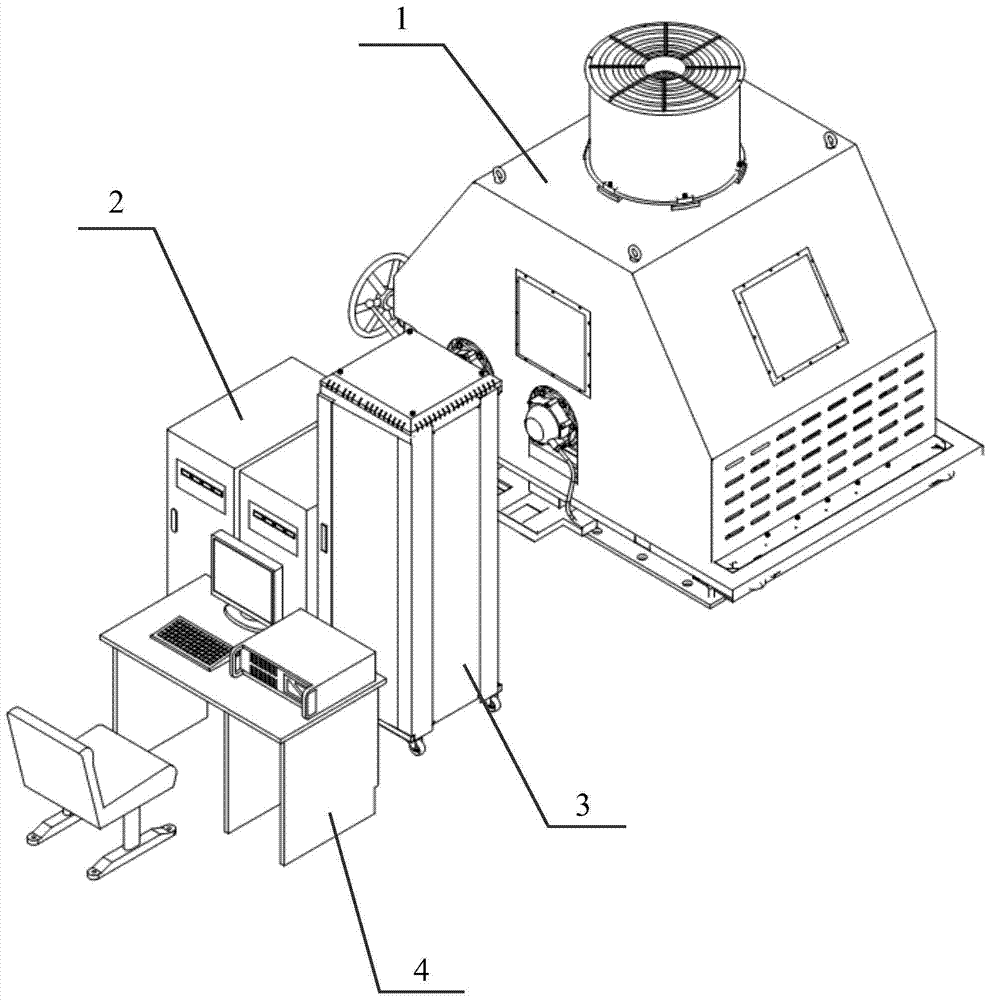

[0061] Such as figure 1 As shown, the high-speed EMU shaft end grounding device wear test bench of the present invention is mainly composed of a test bench 1, a constant current source 2, an electric control cabinet 3 and an industrial computer 4; the test bench 1 mainly carries out loading and Power-on performance and fatigue test, the constant current source 2 is used to provide a stable current to the grounding device to simulate the current transmission in the actual operation process, the electric control cabinet 3 is used to display the speed, temperature, loading force, etc. of the test bench 1 and the motor The operation of the fan is switched on and off and the speed is controlled; the industrial computer 4 is used to record and display the data that needs to be measured in various tests, as well as the operation of the entire system.

[0062] The industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com