Detection method of impurities in sulfur dioxide from tail gas recovery

A technology for the recovery of sulfur dioxide and tail gas, which is applied in the field of analysis to achieve the effects of high accuracy, good control of production and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

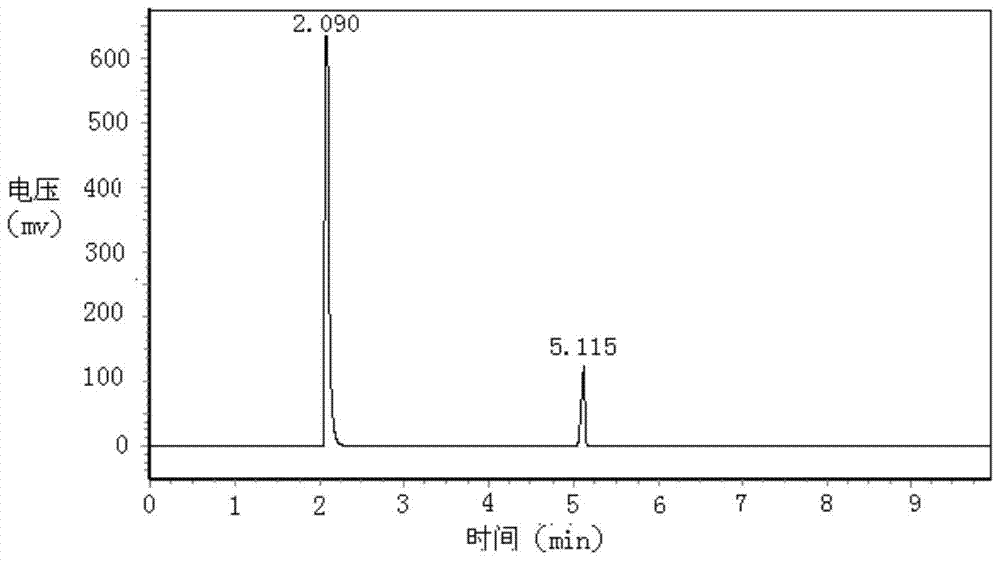

Embodiment 1

[0050] (1) The sulfur dioxide recovered from the tail gas of producing sucralose is naturally volatilized at room temperature, and a small amount of residue is not volatilized;

[0051] (2) Add 3 mL of methanol to dissolve the volatile residue and weigh it;

[0052] (3) According to the production process analysis, it can be known that the impurity contained therein is trichloroethane, and the substance obtained in step (2) is detected by gas chromatography, and the standard substance is used to locate, and the normalized percentage content of each peak is recorded, and the impurity three Ethyl chloride was quantitatively analyzed.

[0053] Described gas chromatography, working condition is as follows:

[0054] Chromatographic column: HP-5 capillary column, column length 30m, column inner diameter 0.25mm;

[0055] The stationary phase of the chromatographic column is 5% phenyl-95% methylpolysiloxane stationary phase;

[0056] Carrier gas: nitrogen;

[0057] The carrier gas...

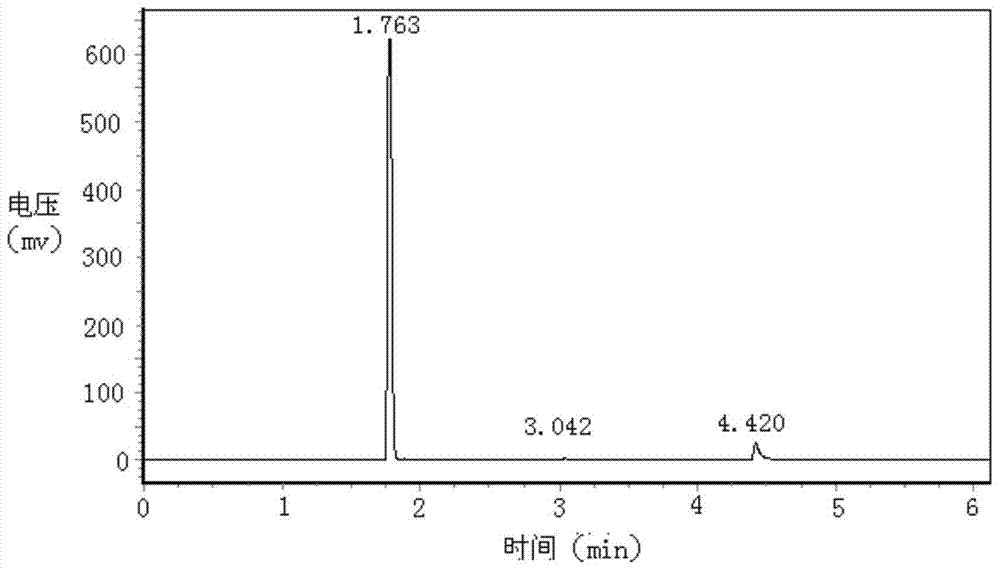

Embodiment 2

[0074] (1) by producing the sulfur dioxide 400g that terephthaloyl chloride tail gas reclaims, volatilize naturally at room temperature, have a small amount of residue and can not volatilize;

[0075] (2) Add 3 mL of ethanol to dissolve the volatile residue and weigh it;

[0076] (3) According to the production process analysis, it can be known that the impurity contained therein is DMF, and the substance obtained in step (2) is detected by gas chromatography, and the standard substance is used to locate, and the normalized percentage content of each peak is recorded, and the impurity trichloroethane Perform quantitative analysis.

[0077] Described gas chromatography, working condition is as follows:

[0078] Chromatographic column: HP-5 capillary column, column length 30m, column inner diameter 0.25mm;

[0079] The stationary phase of the chromatographic column is 5% phenyl-95% methylpolysiloxane stationary phase;

[0080] Carrier gas: nitrogen;

[0081] The carrier gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com