Detection method for detecting isophorone diisocyanate by using gas chromatography-mass spectrometer

A technology of isophorone diisocyanate and GC-MS, which is applied in the field of analysis, can solve the problems of undetected detection of IPDI, etc., and achieve the effect of high accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

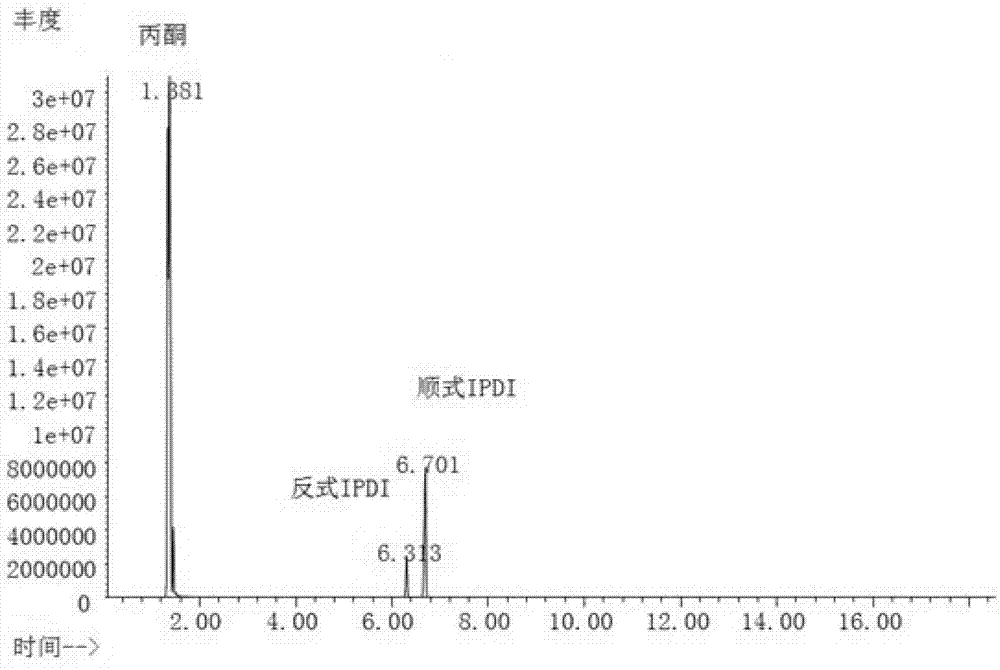

Embodiment 1

[0028] There is an existing batch of isophorone diisocyanate (IPDI) cargo, the quantity is 100 kg, and the effective content of IPDI in this batch of cargo needs to be tested.

[0029] The chromatographic conditions used: the chromatographic column is HP-5MS5%PhenylMethylSilox capillary column; the column temperature is 150°C for 2min, and the temperature is raised to 200°C at 5°C / min for 10min; helium is used as the carrier gas, and the carrier gas pressure is 91.92kMPa , the gas flow rate is 0.8ml / min; the gasification chamber temperature is 260°C; the split ratio is 30:1;

[0030] The mass spectrometry conditions used: ion source is EI ion source; ionization voltage is 70eV, ion source temperature is 230°C; quadrupole temperature is 150°C; transfer line temperature is 280°C.

[0031] Specific steps include:

[0032] (1) Configure IPDI standard solution

[0033] Accurately weigh 10.2mg of IPDI standard in a 100mL volumetric flask, and dilute to the mark with acetone to mak...

Embodiment 2

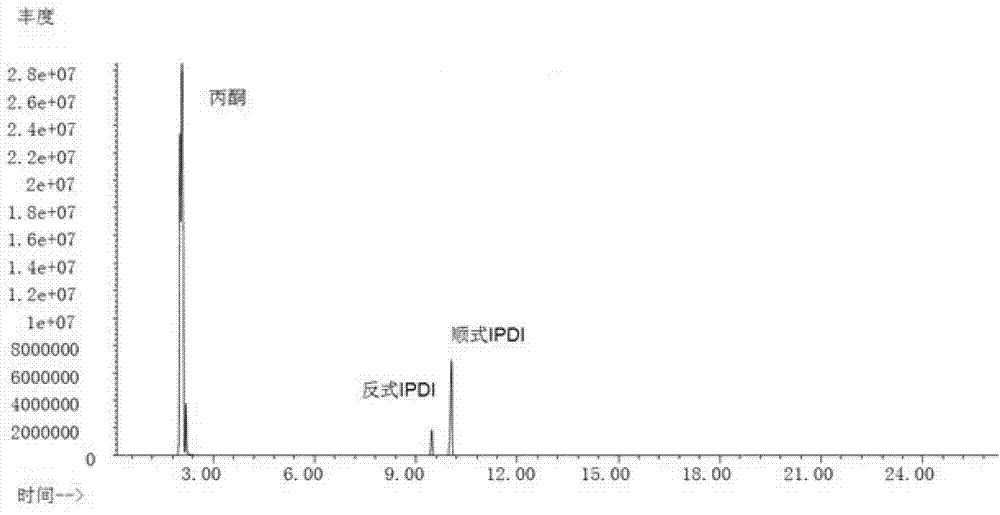

[0048] There is an existing batch of isophorone diisocyanate (IPDI) cargo, the quantity is 200 kg, and the effective content of IPDI in this batch of cargo needs to be tested.

[0049] The chromatographic conditions used: the chromatographic column is HP-5MS5%PhenylMethylSilox capillary column; the column temperature is 150°C for 2min, and the temperature is raised to 200°C at 5°C / min for 10min; helium is used as the carrier gas, and the carrier gas pressure is 91.92kMPa , the gas flow rate is 1.0ml / min; the gasification chamber temperature is 260°C; the split ratio is 30:1;

[0050] The mass spectrometry conditions used: ion source is EI ion source; ionization voltage is 70eV, ion source temperature is 230°C; quadrupole temperature is 150°C; transfer line temperature is 280°C.

[0051] A kind of method that utilizes gas spectrometer to detect isophorone diisocyanate (IPDI), concrete steps comprise:

[0052] (1) Configure IPDI standard solution

[0053] With embodiment 1;

...

Embodiment 3

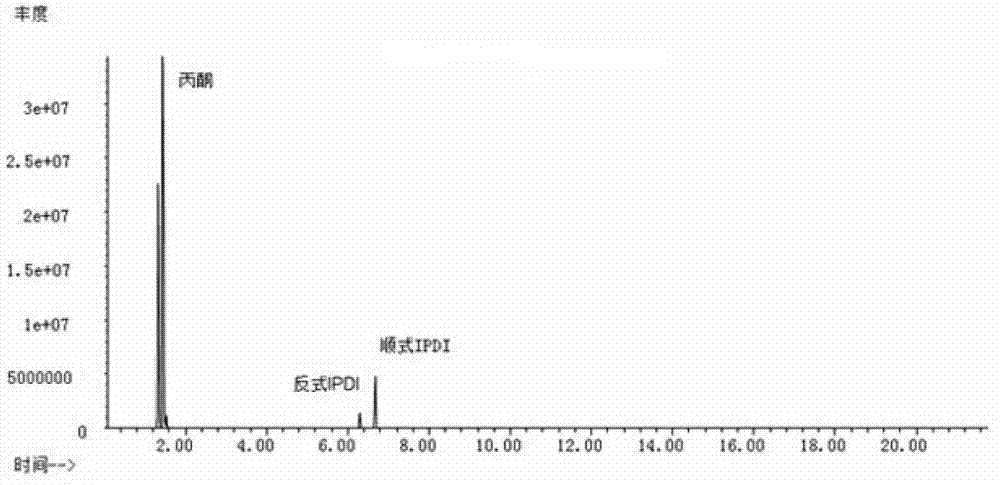

[0068] There is an existing batch of isophorone diisocyanate (IPDI) cargo, the quantity is 500 kg, and the effective content of IPDI in this batch of cargo needs to be tested.

[0069] The chromatographic conditions used: the chromatographic column is HP-5MS5%PhenylMethylSilox capillary column; the column temperature is 150°C for 2min, and the temperature is raised to 200°C at 5°C / min for 10min; helium is used as the carrier gas, and the carrier gas pressure is 91.92kMPa , the gas flow rate is 1.5ml / min; the gasification chamber temperature is 260°C; the split ratio is 30:1;

[0070] The mass spectrometry conditions used: ion source is EI ion source; ionization voltage is 70eV; ion source temperature is 230°C; quadrupole temperature is 150°C; transfer line temperature is 280°C.

[0071] A kind of method that utilizes gas spectrometer to detect isophorone diisocyanate (IPDI), concrete steps comprise:

[0072] (1) Configure IPDI standard solution

[0073] With embodiment 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com