Vertical electric separation mechanism for electric connector

An electrical connector and connecting mechanism technology, applied to the components, connections, circuits and other directions of the connecting device, can solve the problems of large space occupation, inability to realize automatic control, inability to realize electromagnetic vertical separation of connectors, etc., and achieve simple and convenient operation. , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention proposes a vertical electrical separation mechanism for an electrical connector, which realizes automatic unlocking and separation in the vertical direction of the electrical connector. Compared with the existing manual vertical separation electrical connector, it has the ability to realize automatic unlocking and separation through electrical signal control. Advantages, improve the convenience of use, and save the use of space.

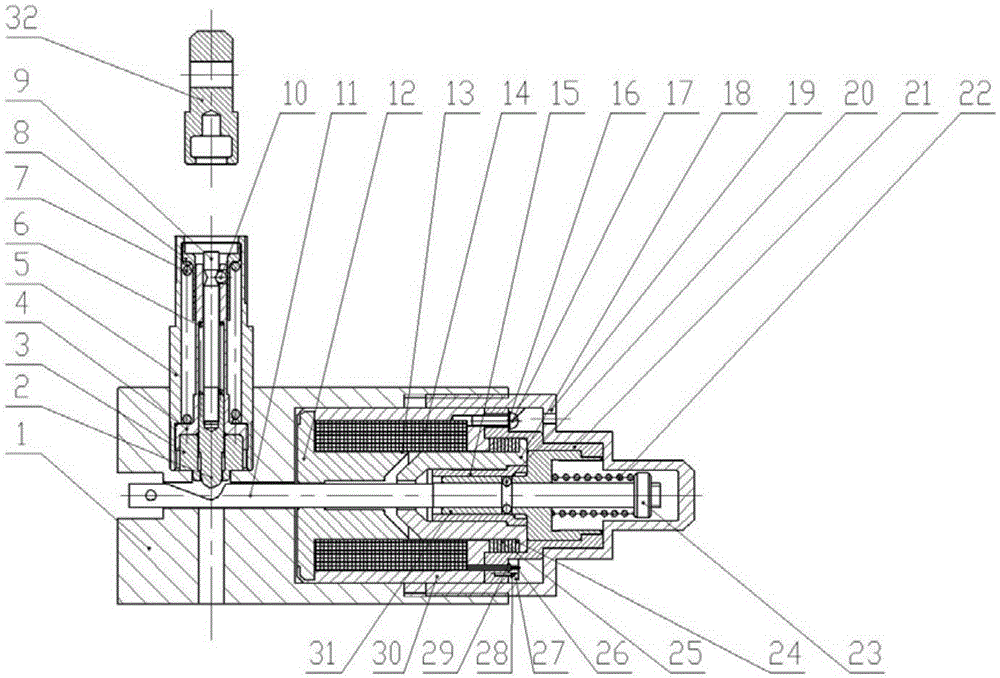

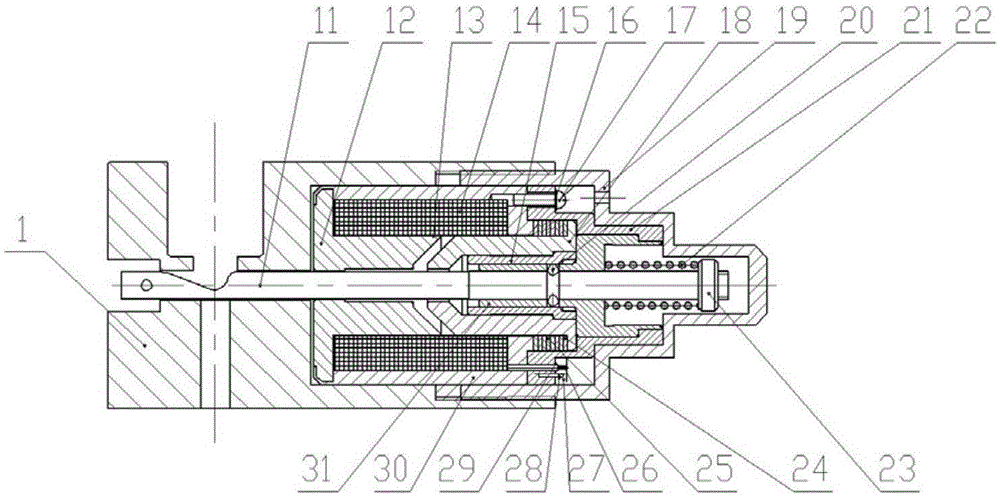

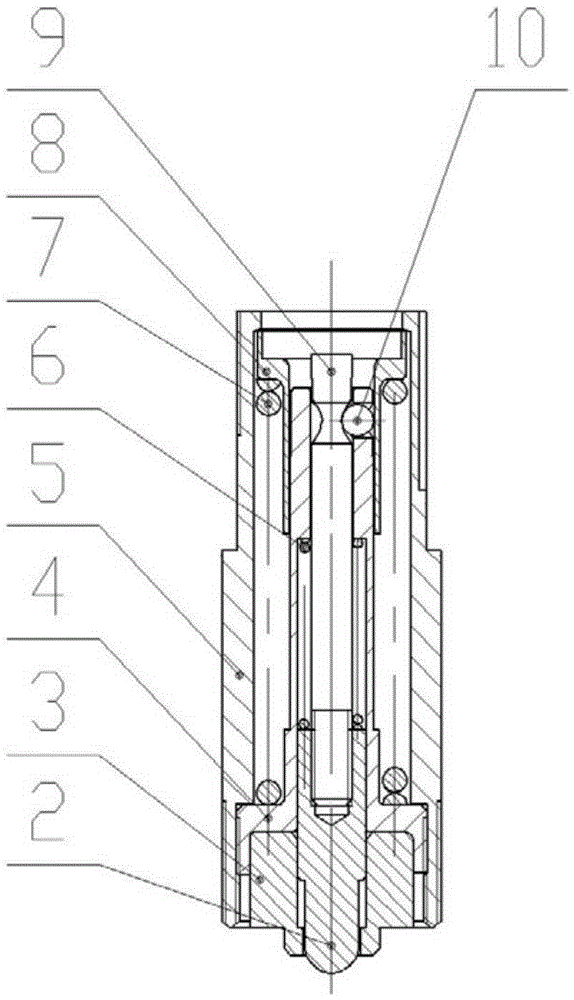

[0022] A vertical electrical separation mechanism of an electrical connector such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes support 1, top cap 2, movable sleeve 3, steel ball positioning sleeve 4, jacket 5, top pressure spring 6, separation spring 7, sheath 8, ejector rod 9, steel ball 10, pin rod 11, Yoke 12, bushing 13, wire package 14, armature adhesive sleeve 15, spring washer 16, slotted cylindrical head screw 17, armature 18, parallel nut 19, steel ball 20, wire package cover 21, preloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com