Stator assembly and eddy current retarder for eddy current retarder

An eddy current retarder and stator assembly technology, applied in the field of auto parts, can solve problems such as affecting vehicle passability, and achieve the effect of increasing the torque of the retarder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

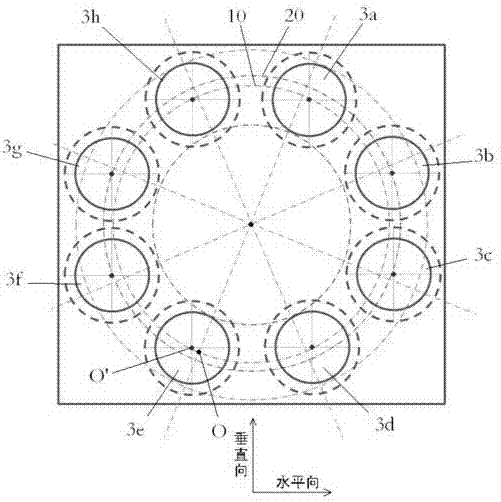

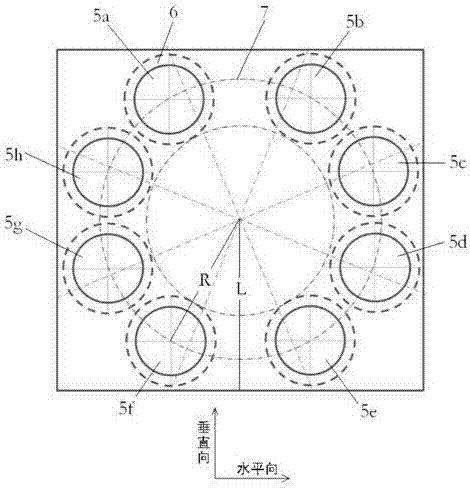

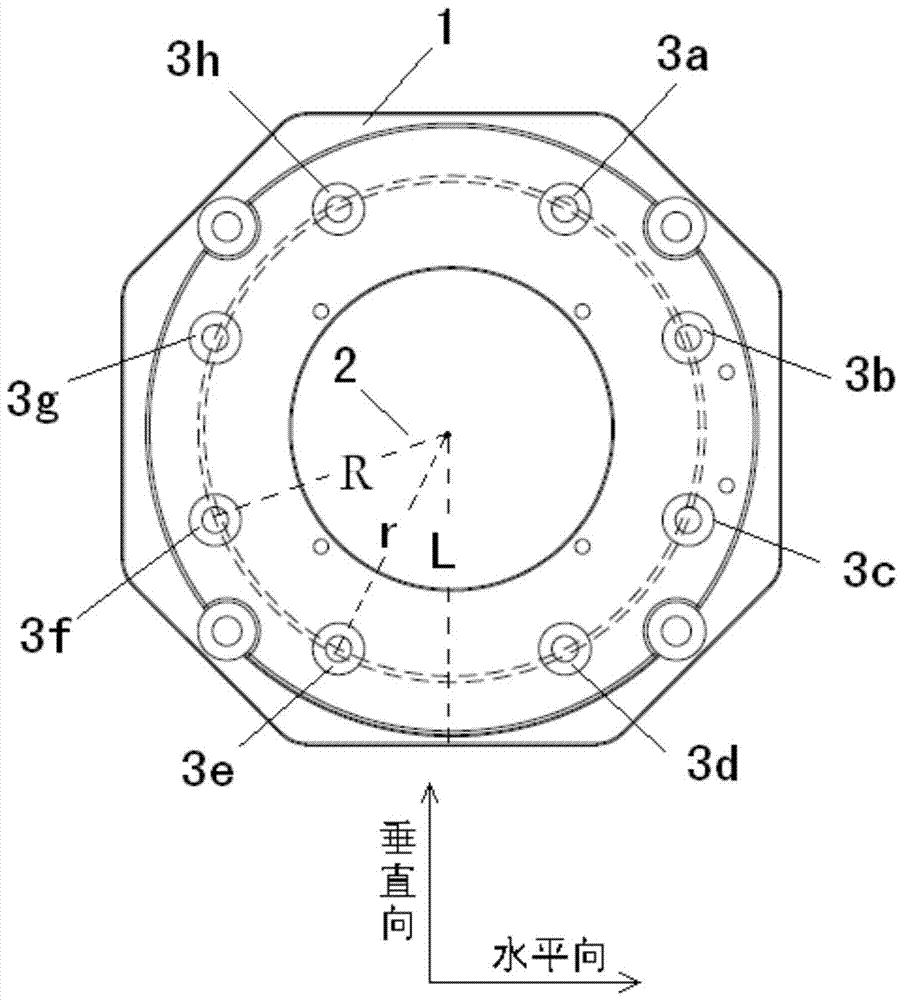

[0030] The stator assembly of the eddy current retarder provided by the present invention is also composed of 8 or 6 magnetic poles, wherein the distance from the two lowest poles to the center of the circle is r, and the distance from the rest of the poles to the center of the circle is greater than or equal to r . figure 1 It is the first embodiment of the eddy current retarder provided by the present invention, such as figure 1 Therefore, the magnetic poles 3e and 3d are located at the bottom of the retarder stator assembly. The distance between the circumference of the magnetic poles 3e and 3d and the center of the circle is r. In this way, compared with the prior art, when the retarder is installed on the vehicle, the space dimension of the retarder is still L, which remains unchanged. The distance from the circumference of the magnetic poles 3b, 3c, 3f, 3g, 3a and 3h to the center of the circle is R, and R is greater than r. The formula for calculating the total torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com