Design method of intelligent module encapsulation structure for electric actuator

An electric actuator and module packaging technology, applied in the direction of electrical equipment housing/cabinet/drawer, electrical components, sealed housing, etc., can solve the problems of space layout, low protection and sealing, low operational reliability, etc., to improve the yield , The effect of strong dustproof and waterproof ability and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

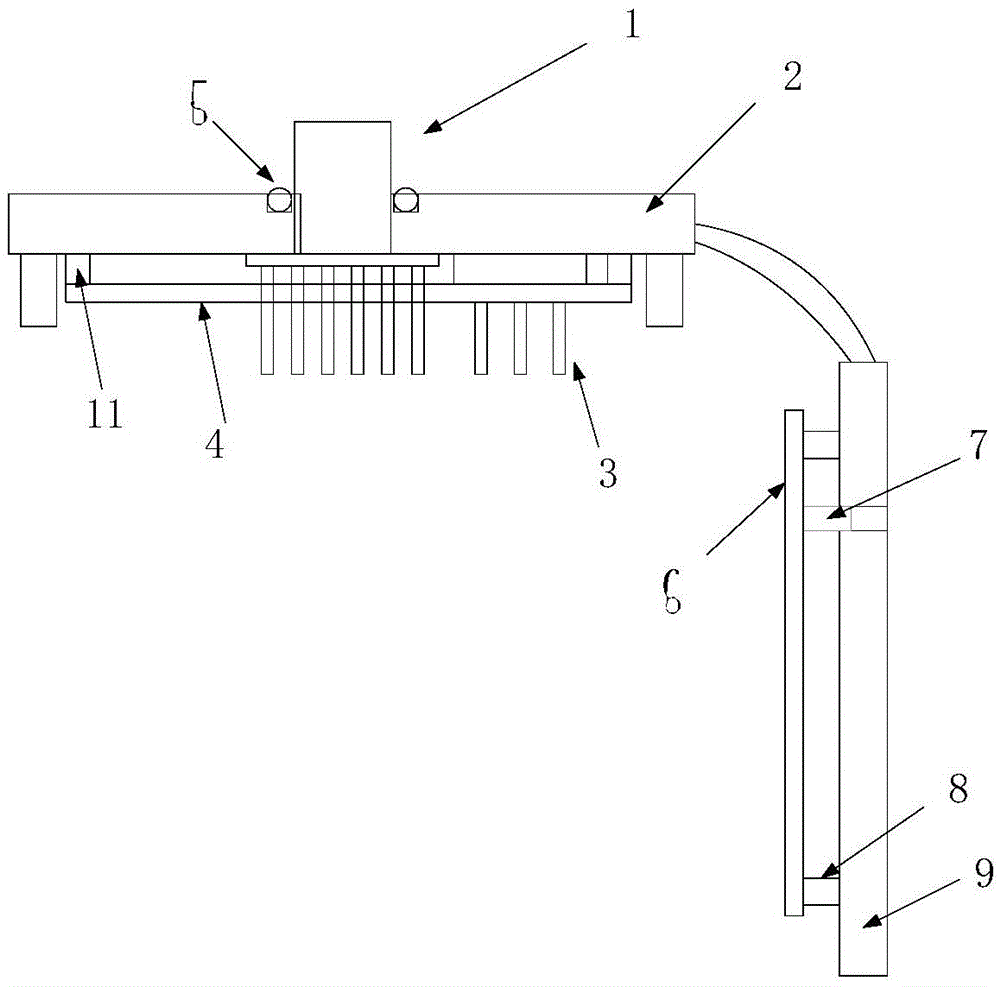

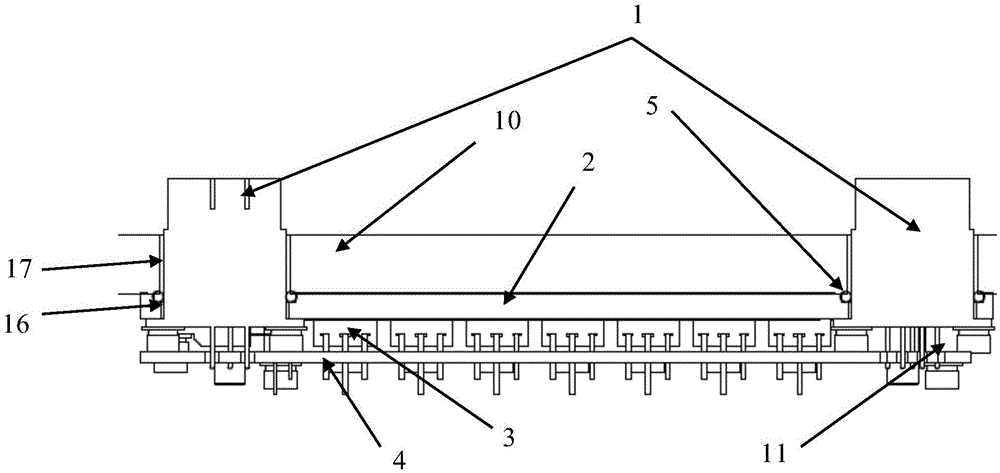

[0041] According to the present invention, the intelligent module structure of the electric actuator is as follows: figure 1 As shown, it mainly includes: aviation plug 1, first aluminum plate 2, MOS tube 3, first PCB board 4, sealing O-ring 5, second PCB board 6, light guide column 7, first sealing rivet nut 11, second Seal rivet nut 8, second aluminum plate 9.

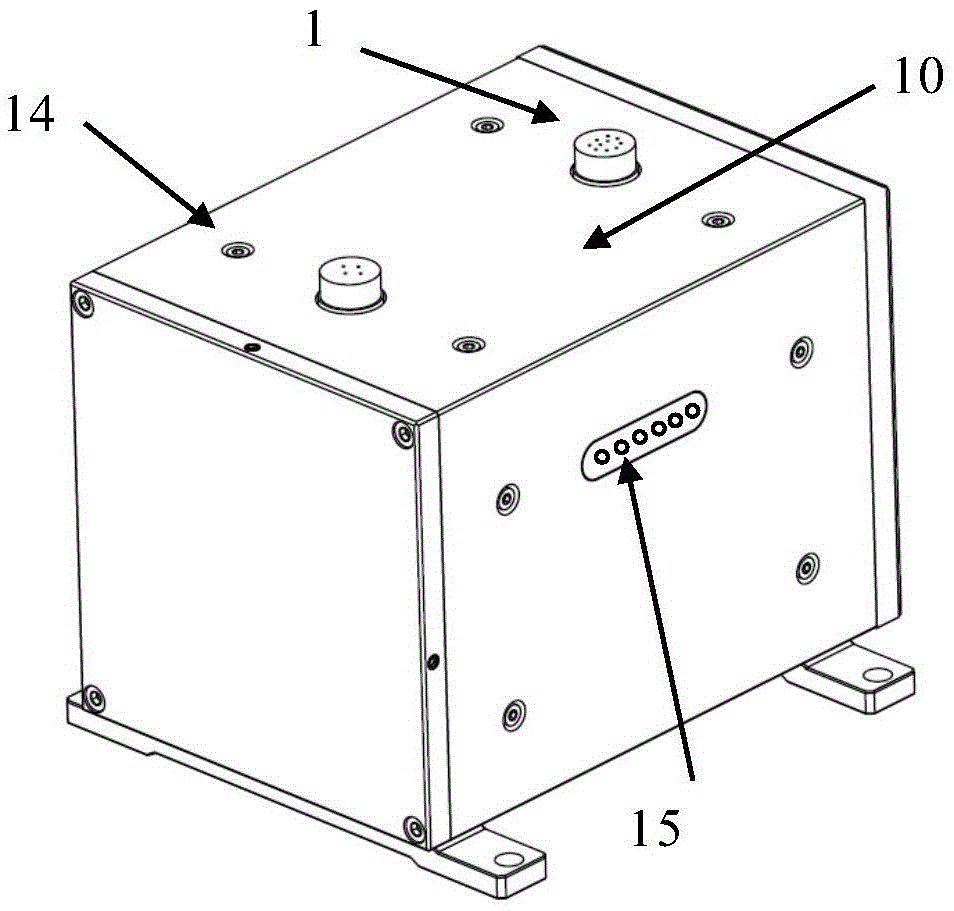

[0042] The mode that the intelligent module is installed in the sealed casing 10 is as follows: figure 2 As shown, the screw 14 is screwed into the second sealing rivet nut 8 of the intelligent module from the outside of the sealed casing 10, and the O-ring 5 is pressed to seal the gap between the aviation plug 1 body and the first aluminum plate 2. At the same time, a light guide hole 15 is opened in a corresponding part outside the sealed casing 10 and sealed with PC material 12 to realize the light guide function.

[0043] figure 1 , figure 2 Shown are the schematic diagram of the structure of the intelligen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com